Robot system and method for producing a to-be-processed material

A technology of robot system and processed object, which is applied in the direction of manufacturing tools, general control system, control/regulation system, etc., and can solve the problems of laser blurring and whitening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

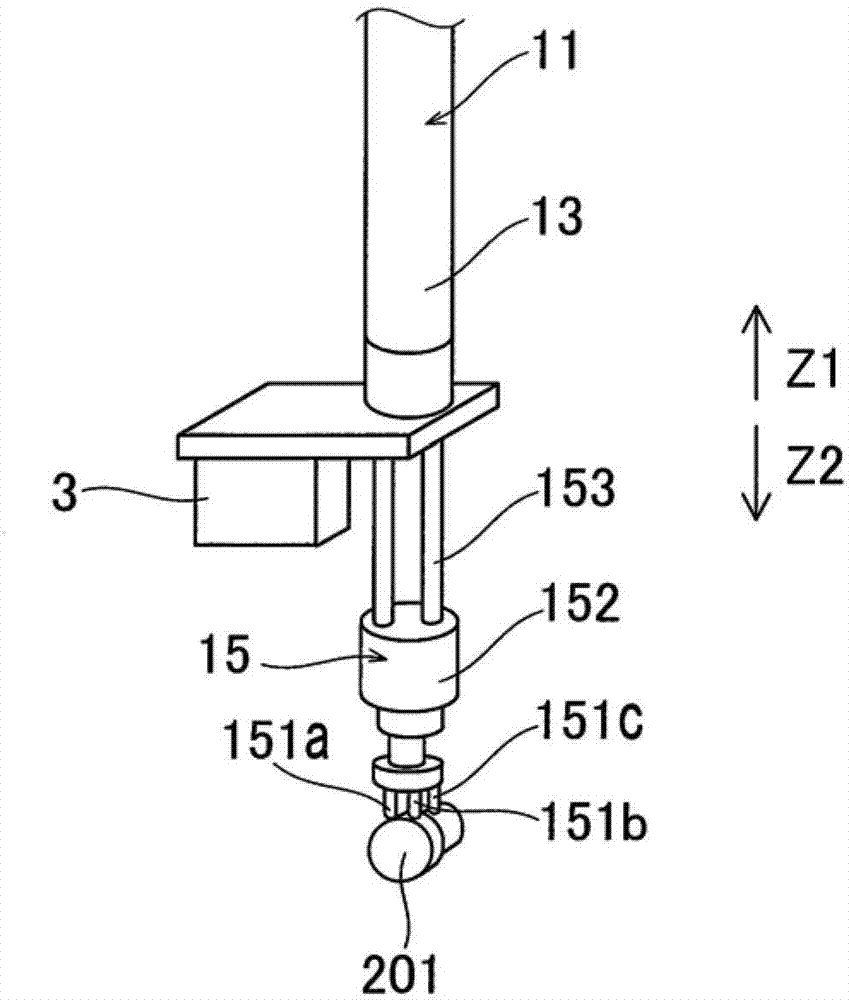

[0046] Embodiments of the present invention will be described below based on the drawings.

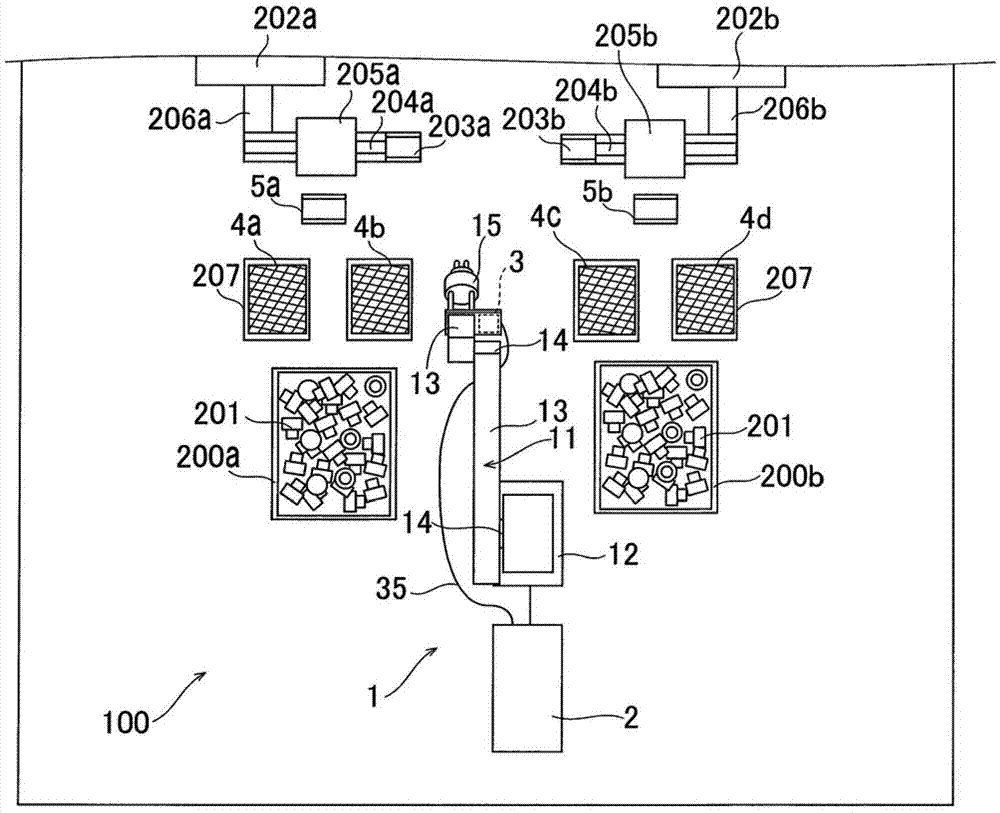

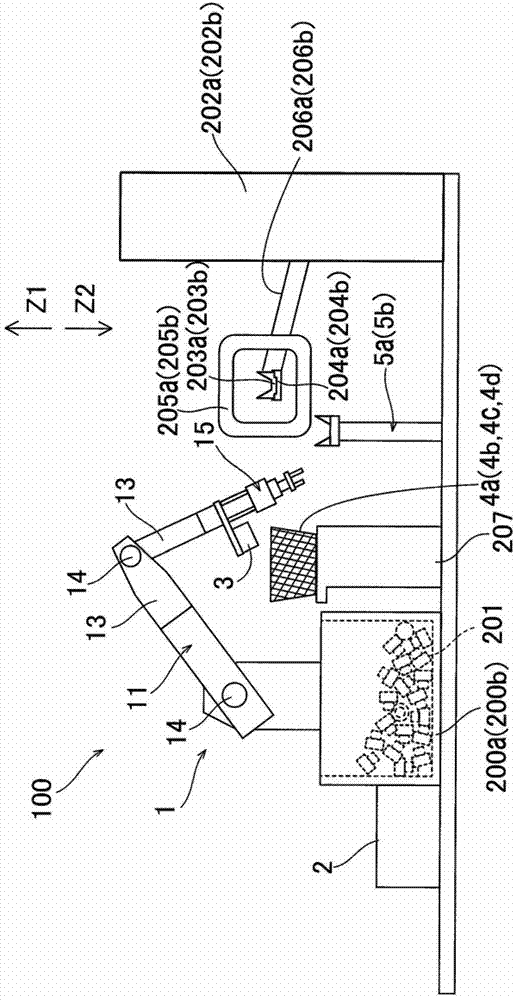

[0047] First, refer to Figure 1 to Figure 9 The configuration of the robot system 100 of this embodiment will be described.

[0048] Such as figure 1 As shown, the robot system 100 has: a robot 1; a robot controller 2, which is used to control all actions of the robot system 100; a configuration state detection part 3; four temporary placement parts 4a, 4b, 4c and 4d, which are used for the Temporary placement; and changing stations 5a and 5b, which are used to change the workpiece 201. Also, two workpiece pallets 200 a and 200 b having a plurality of workpieces 201 arranged therein are arranged adjacent to the robot system 100 . Moreover, two of the four temporary storage parts 4a, 4b, 4c, and 4d are respectively arranged with respect to each workpiece pallet 200a, 200b. In addition, the robot controller 2 is an example of the "control part" of this invention. Moreover, the temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com