Hydraulic control directional control valve

A technology of hydraulically controlled reversing valve and pilot reversing valve, which is applied in mining equipment, earthwork drilling, mine roof support, etc. Less source, compact and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

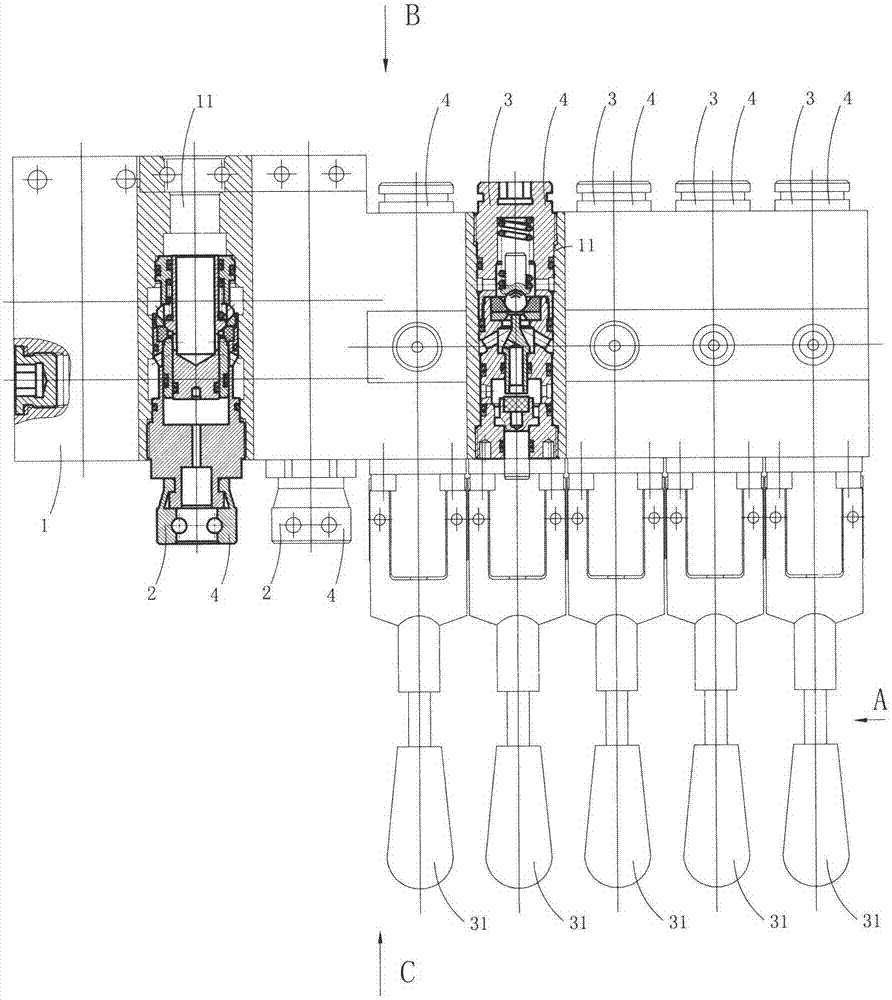

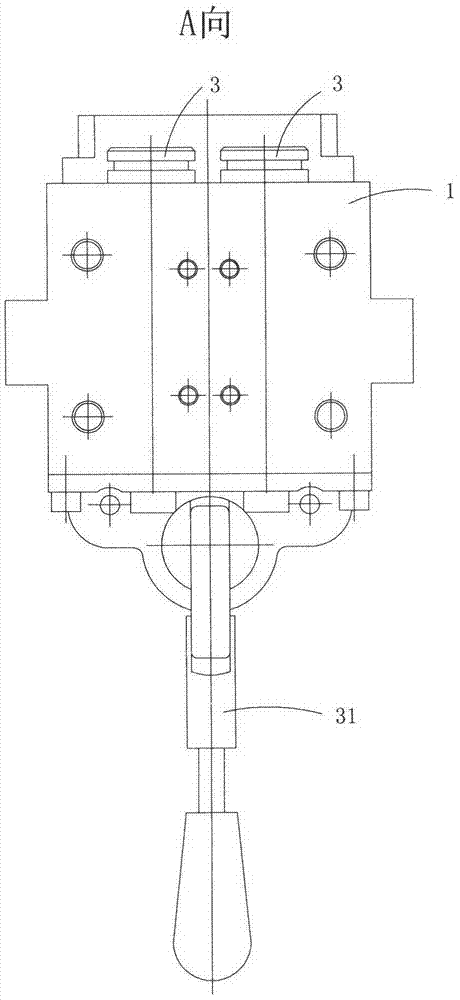

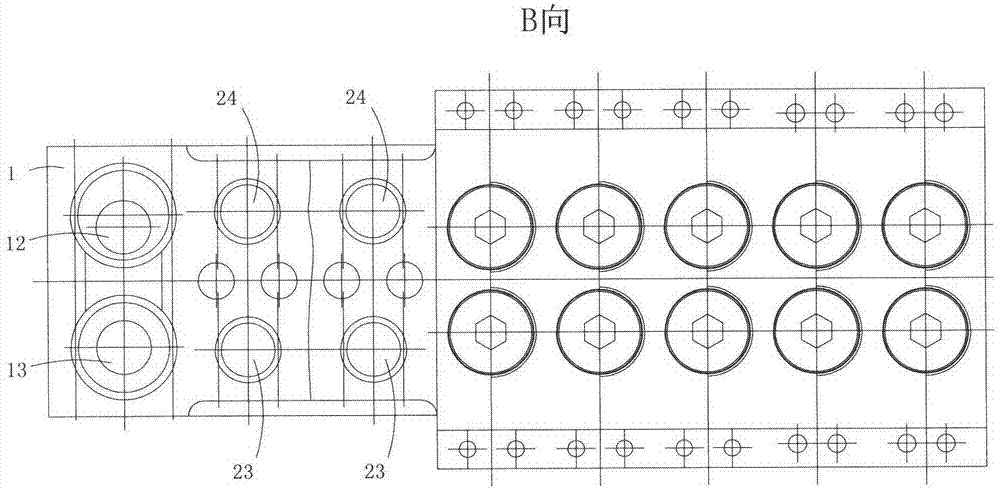

[0017] Figure 1 to Figure 4 A specific embodiment of the invention is shown in which figure 1 It is a structural schematic diagram of the present invention; figure 2 yes figure 1 A-direction view; image 3 yes figure 1 B direction view; Figure 4 yes figure 1 C direction view.

[0018] This embodiment is a hydraulic reversing valve used in a downhole hydraulic support, see Figure 1 to Figure 4 As shown, it includes a valve body 1; two large-flow main control valves 2 and five medium-flow pilot control valves 3 with operating mechanisms 31 are arranged in the valve body; two large-flow main control valves are adjacently arranged side by side, and five The medium flow pilot directional control valves are arranged adjacently and side by side.

[0019] The valve body includes seven sockets 11 provided with internal thread areas; the main control valves with large flows and the pilot reversing valves with medium flow are equipped with cartridge-type spool assemblies 4 wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com