Cable box

A cable box, dust technology, applied in the direction of engine components, machines/engines, casings, etc., can solve problems such as oil leakage that can no longer be reliably prevented, and achieve the effects of preventing dust intrusion, suppressing manufacturing costs, and suppressing increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] Hereinafter, embodiments of the present invention will be described in detail based on the drawings.

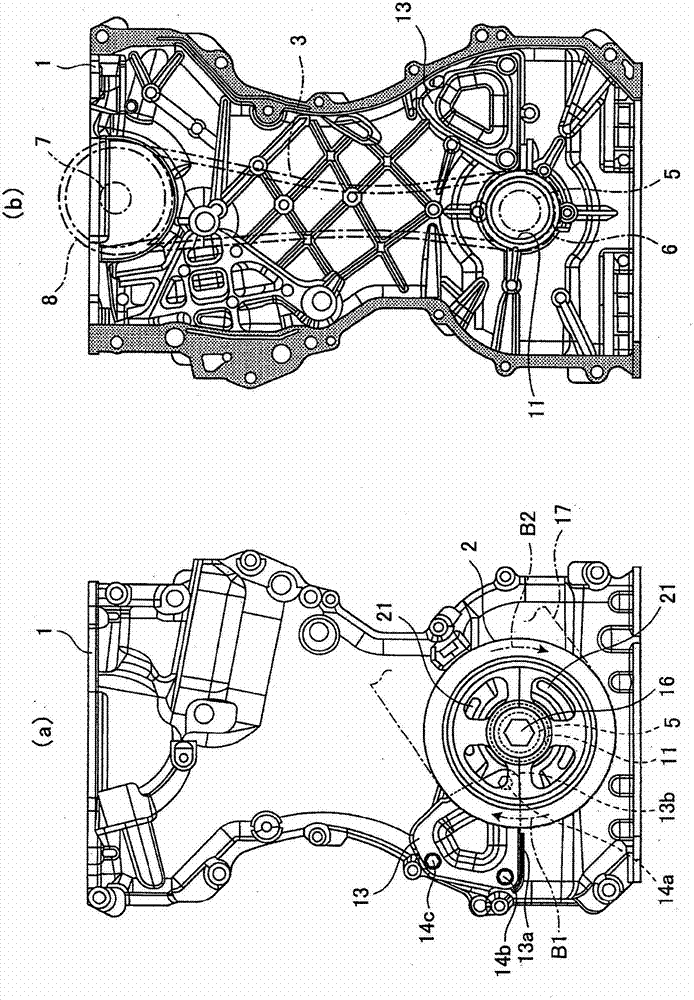

[0046] Such as figure 1 As shown in (a), the crank pulley 2 is provided on the surface side of the chain case 1, and on the other hand, as shown in figure 1 As shown in (b), the endless chain 3 is provided on the back side of the chain case 1 .

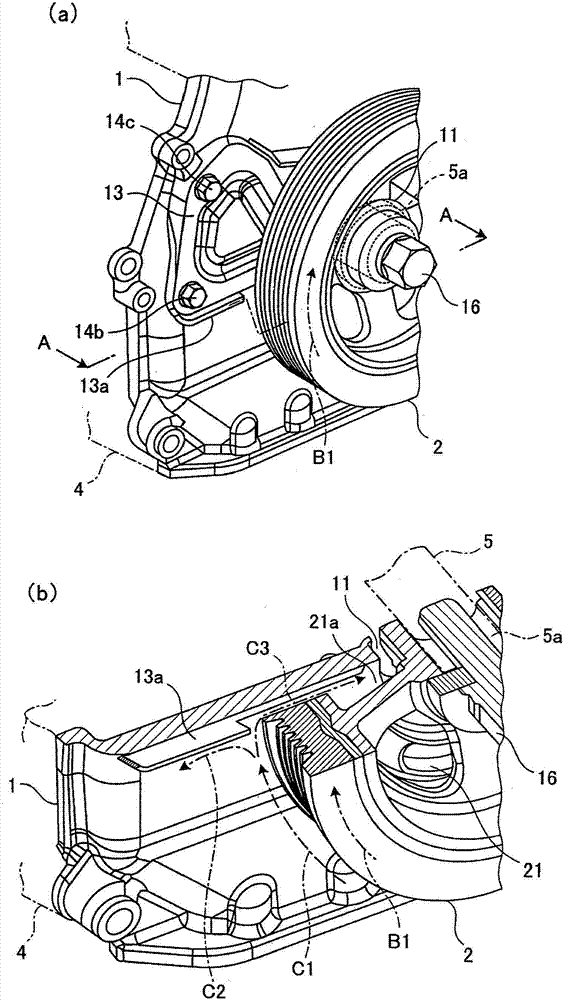

[0047] Such as figure 1 As shown in (b), the chain 3 is respectively wound on the sprocket 6 and the sprocket 8, wherein the sprocket 6 is fixed on the engine 4 (refer to image 3 ) on the crankshaft 5 at the lower part (cylinder block side), the sprocket 8 is fixed on the engine 4 (refer to image 3 ) on the upper (cylinder head side) camshaft 7, and transmits the rotational force of the crankshaft 6 to the camshaft 8. Such as image 3 As shown, the chain case 1 is fixed to the side of the engine (cylinder head and cylinder block) 4 by bolts (not shown), thereby covering the chain 3 .

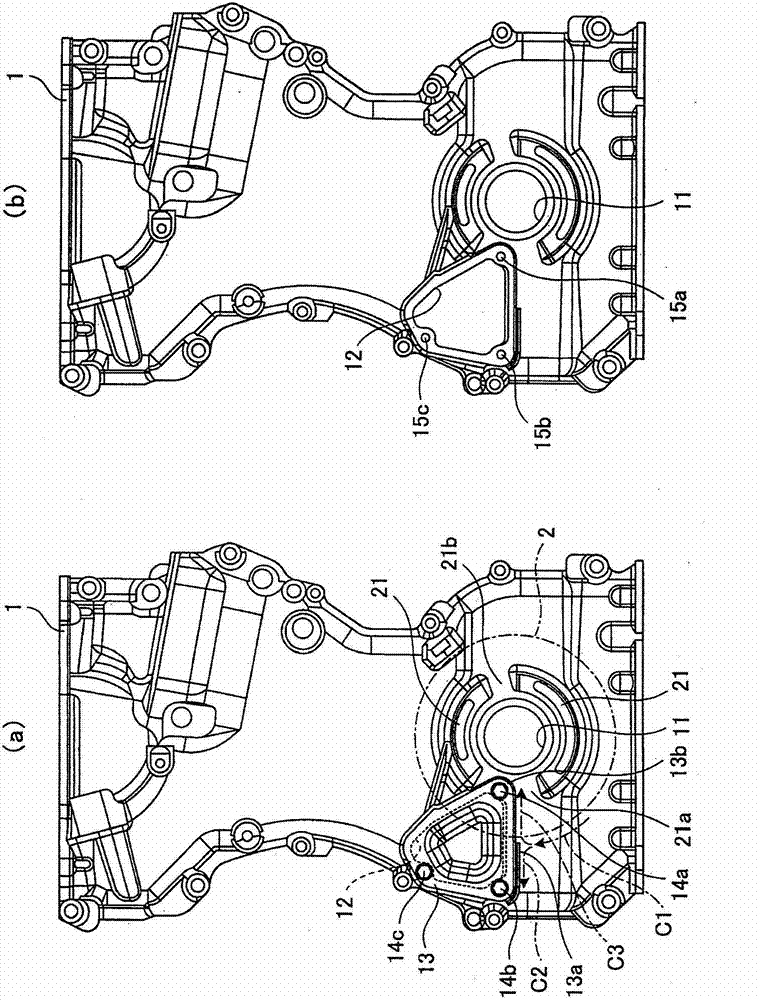

[0048] Such as figure 2 (a), ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com