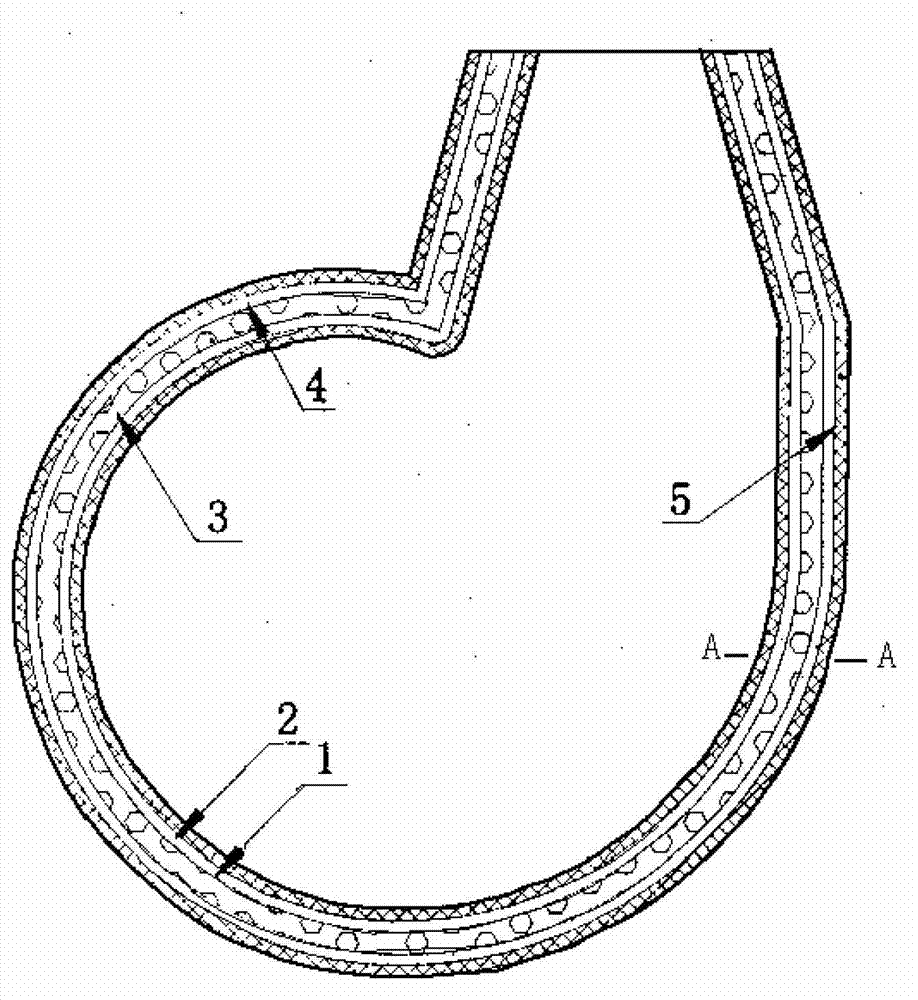

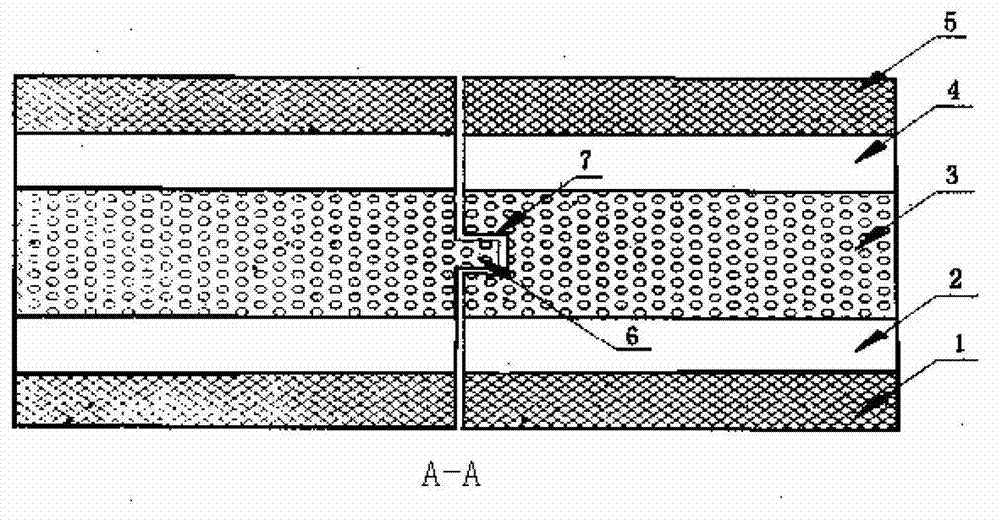

Low-noise centrifugal ventilator casing

A centrifugal fan technology, applied in the direction of machines/engines, mechanical equipment, non-variable pumps, etc., can solve the problems of high cost, difficulty, and complexity, and achieve the effect of light weight, reduced use, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0012] Numerical simulation is used to calculate the noise of the measuring point of a certain centrifugal fan. The noise of the original fan model is about 83 dB. It is composed of 10mm acoustic wipe fabric, 30mm porous foam metal plate, 10mm outer sound-absorbing wipe fabric and 10mm carbon structural steel outer layer. The noise of the fan is reduced to 72 dB, and the noise reduction effect is very significant, which improves the working environment of operators.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com