Solar plane sunward automatic tracking adjusting system

An automatic tracking and adjustment system technology, applied in control/adjustment systems, non-electric variable control, instruments, etc., can solve problems such as manual adjustment, and achieve the effect of strong wind resistance and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The following is a further description of the solar plane sunrise tracking automatic adjustment system of the present invention in conjunction with the accompanying drawings and embodiments.

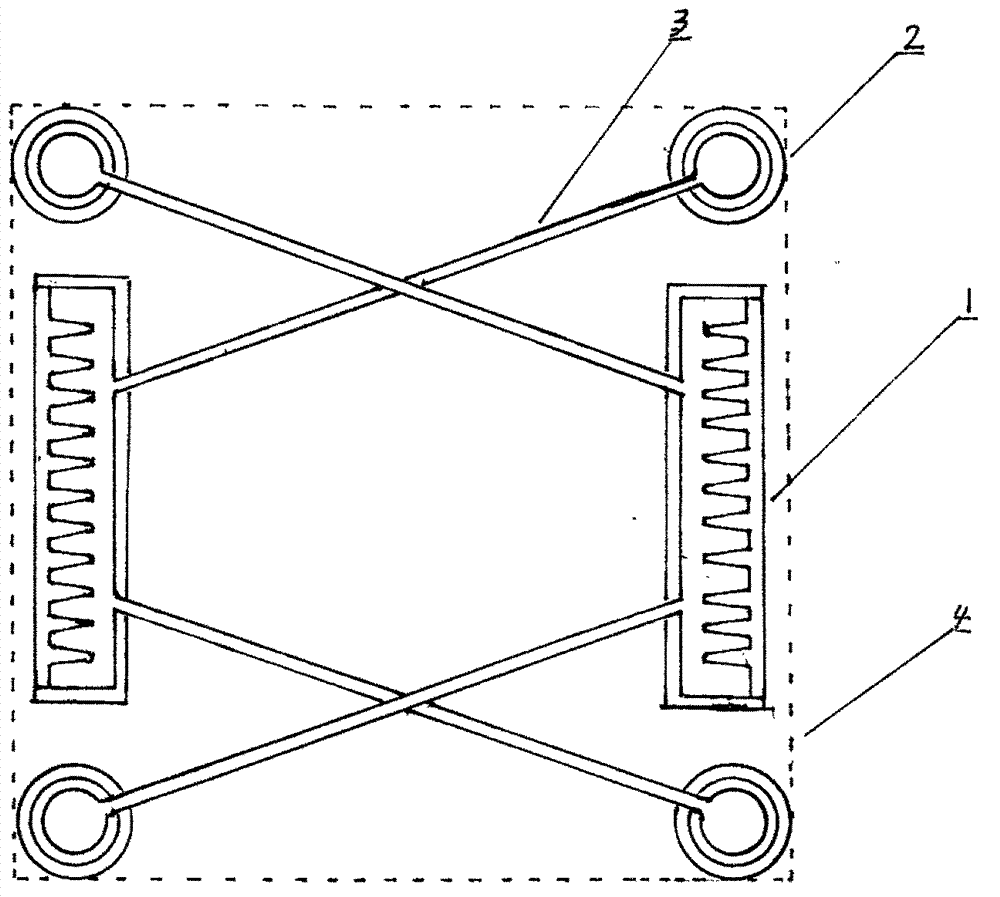

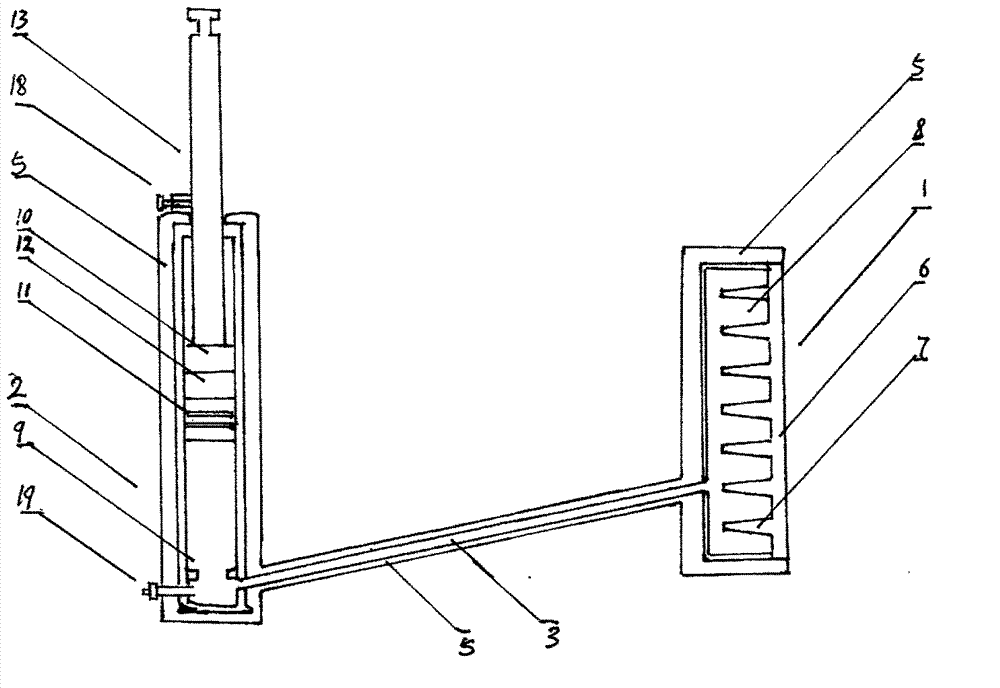

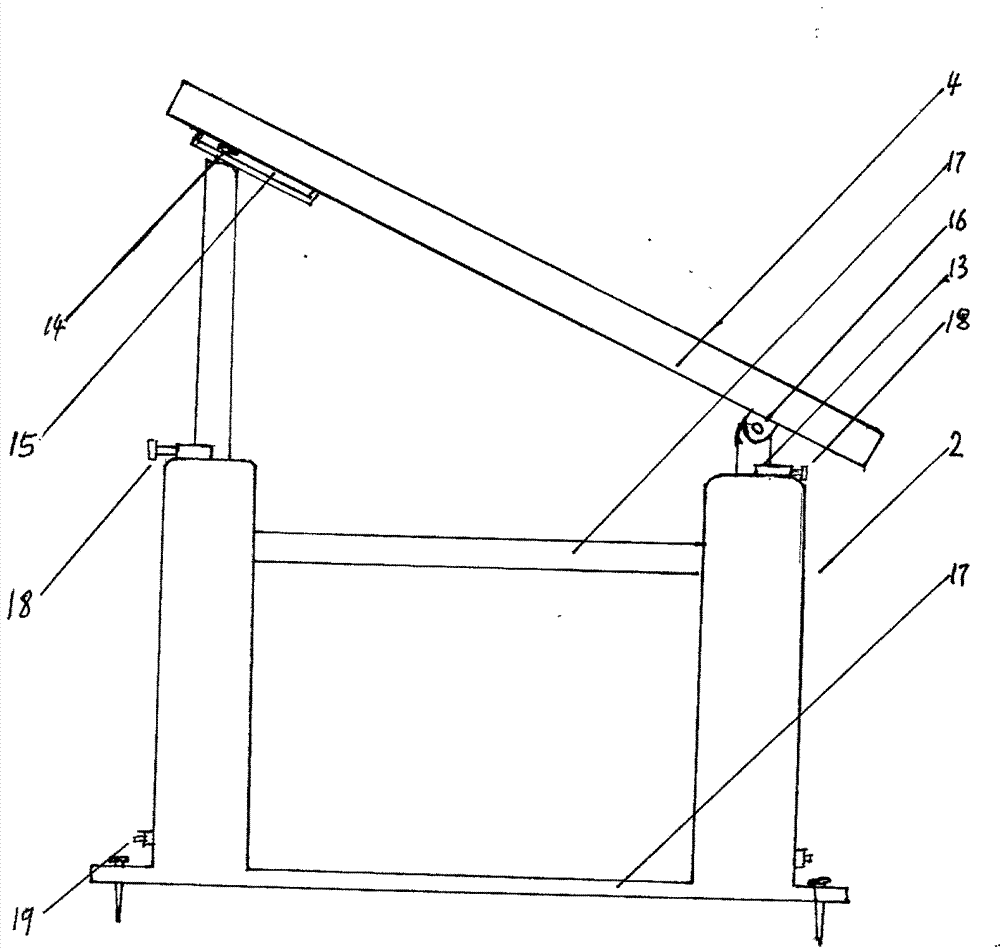

[0016] Any system is divided into organs with different functions to achieve a certain common purpose. The system of the present invention is composed of a solar gas heater (1), an air pressure lifter (2), a high-pressure air pipe (3), and a collection plane (4). ) These organs are composed of several organs, and they have different jobs: the solar gas heater (1) is responsible for heating the gas to increase the pressure of the gas; 2) It is responsible for changing the volume change of the gas into the expansion and contraction of the mandrel; the collection plane (4) provides the placement of solar energy collectors (solar water heaters or solar power panels), and the common purpose of their work is to perform real-time tracking of the collection plane facing the sun to improve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com