Sub-frame iron core structure for disassembling and transporting transformer and transportation method

A transformer and iron core technology, applied in the field of combined lower clamp structure, can solve problems such as dismantling, transportation and on-site installation difficulties, achieve the effects of reducing noise and vibration, increasing integrity and rigidity, and ensuring insulation distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific embodiment of the present invention is described below in conjunction with accompanying drawing:

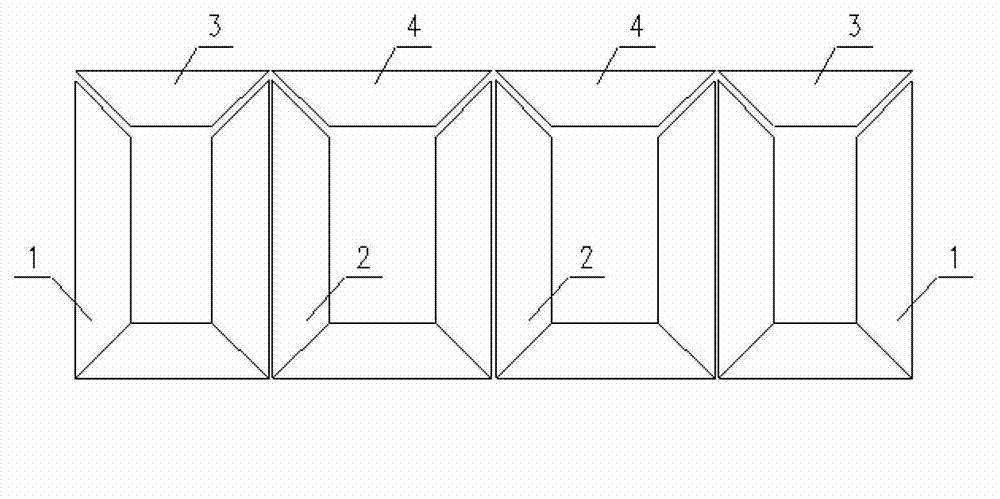

[0029] The specific implementation of the present invention will be described in detail by taking a four-column sub-frame core as an example.

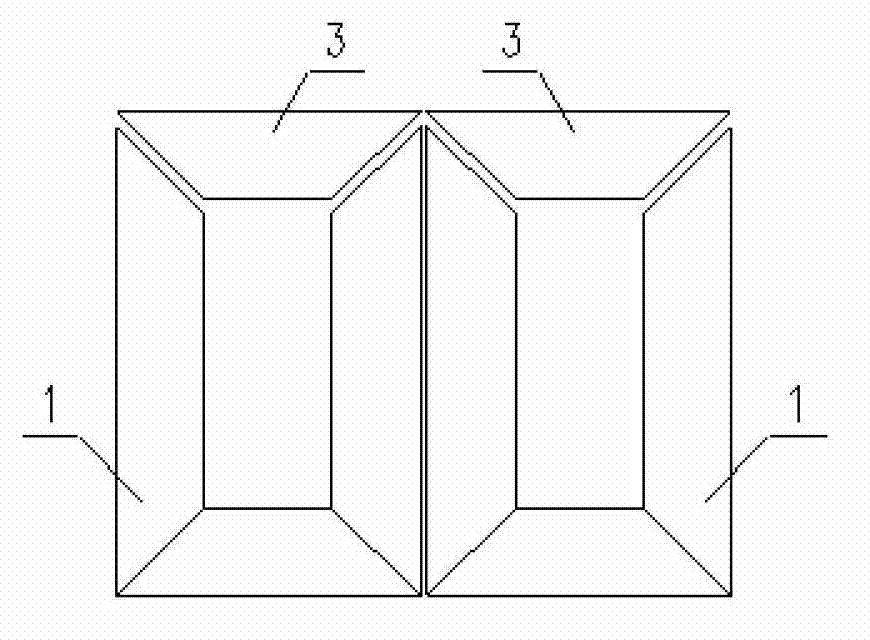

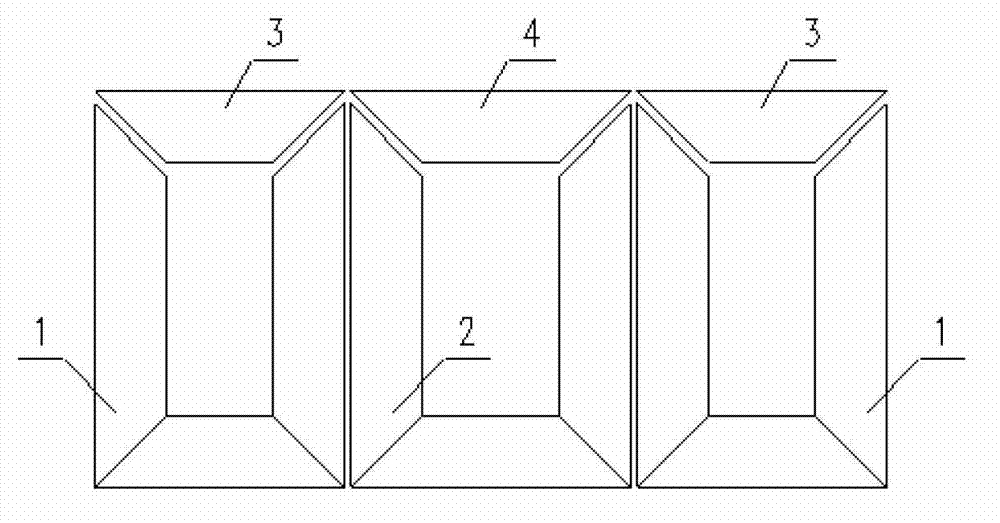

[0030] Such as figure 2 As shown, the iron core is divided into two frames 1 (that is, side columns) and a middle frame 2 (that is, the main column) (the present invention is also applicable to three-column cores and five-column cores, if a three-column core is used, only two frames 1; if a five-column iron core is used, there are two frames 1 and two middle frames 2).

[0031] The sub-frame core structure used for dismantling transport transformers, including side columns, main columns between side columns, upper and lower iron yokes located above and below the main columns, and upper and lower clamps, a main column from The middle is divided into two half columns, one half column forms a U-shaped structure with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com