Motor stator installing tool

A motor stator and tooling technology, which is applied in the manufacture of stator/rotor body, etc., can solve the problems of poor hoisting, heavy weight of the stator, difficulty in securing the stator, etc., and achieves the effects of convenient operation, guaranteed product quality, and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

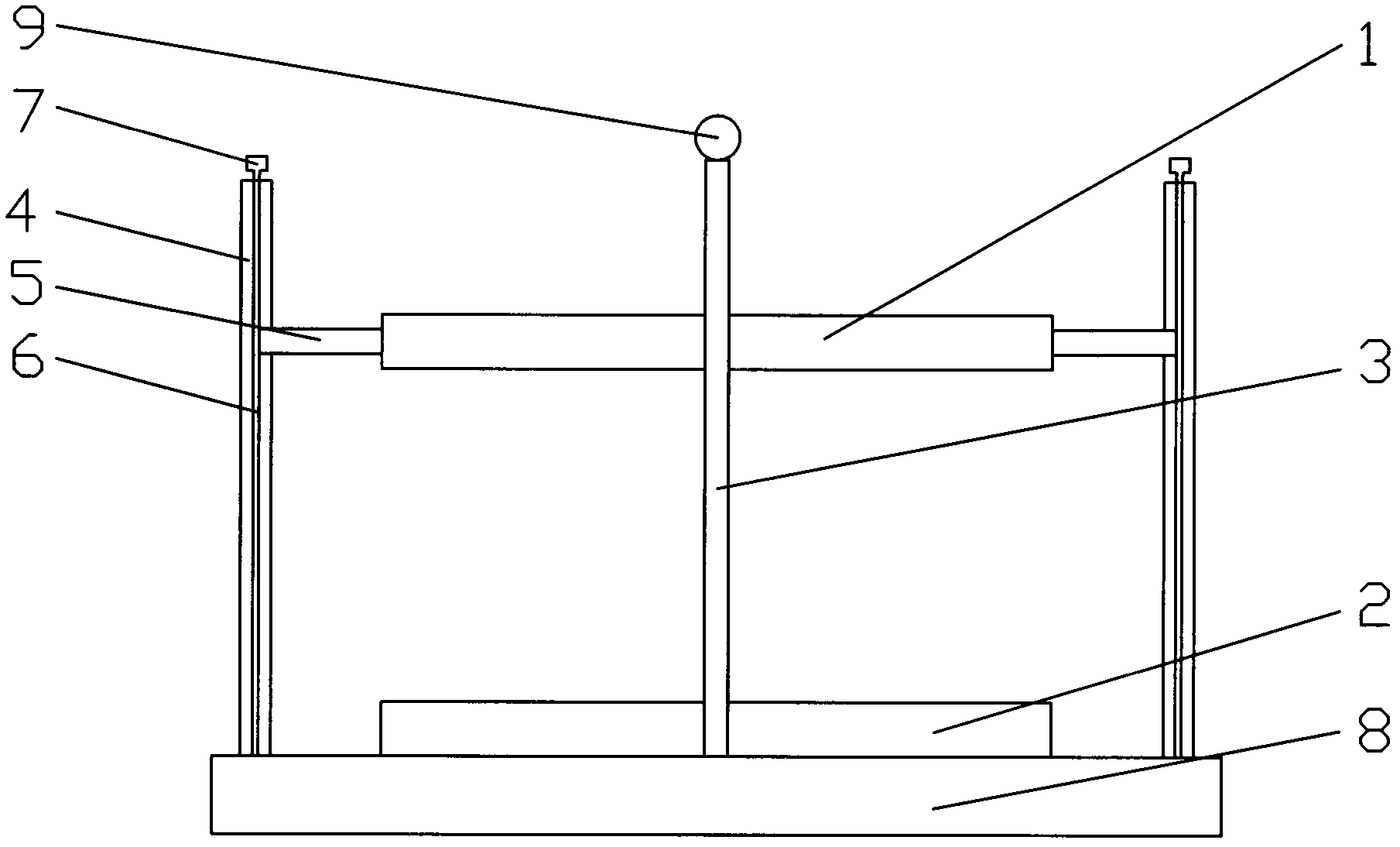

[0012] see figure 1 , a motor stator installation tool, including an upper platen 1, a lower support plate 2, a suspender 3, a side plate 4 and a connecting rod 5, the upper platen 1 and the lower support plate 2 are connected by a suspender 3, and the side A screw 6 is arranged in the plate 4, and the screw 6 is connected with the upper platen 1 through a connecting rod 5, an adjusting nut 7 is arranged on the screw 6, and a groove is opened on the side plate 3.

[0013] In addition, a suspension ring 9' is connected to the end of the suspension rod 3 .

[0014] In addition, a support 8 is provided under the lower support plate 2, and the suppo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com