Package method for printed circuit board (PCB) substrate

A packaging method and substrate technology, applied in the direction of multi-layer circuit manufacturing, etc., can solve the problems of poor positioning accuracy of PCB substrates, achieve stable signal transmission, stable signal transmission, and avoid glue overflow problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

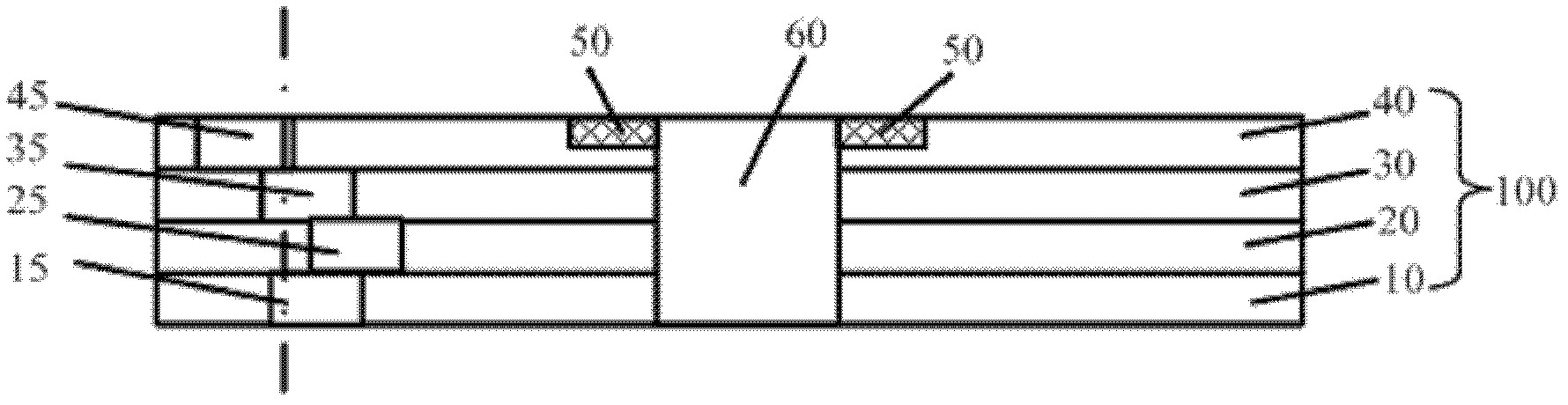

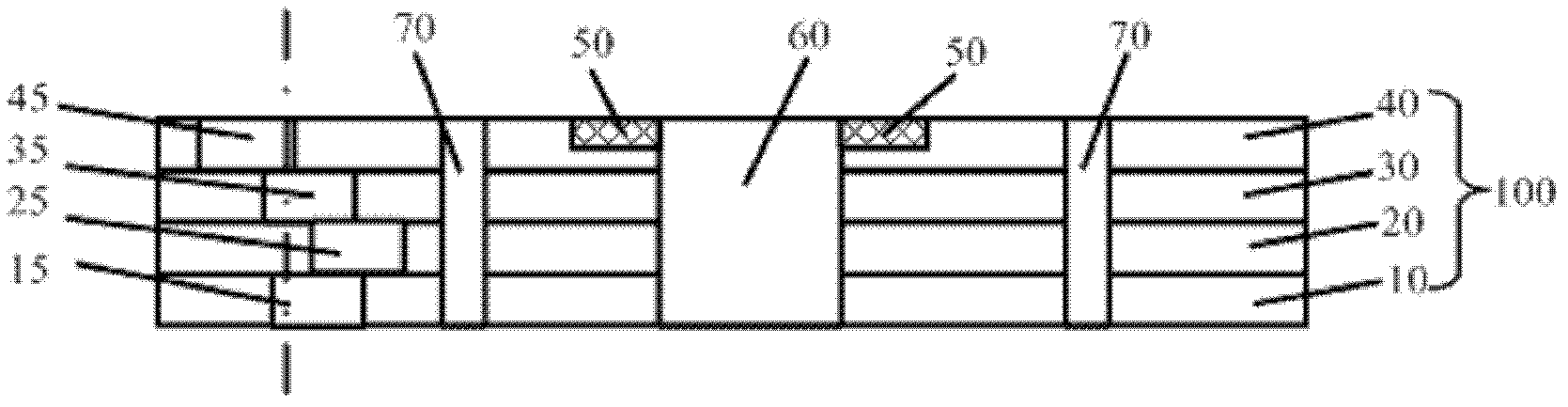

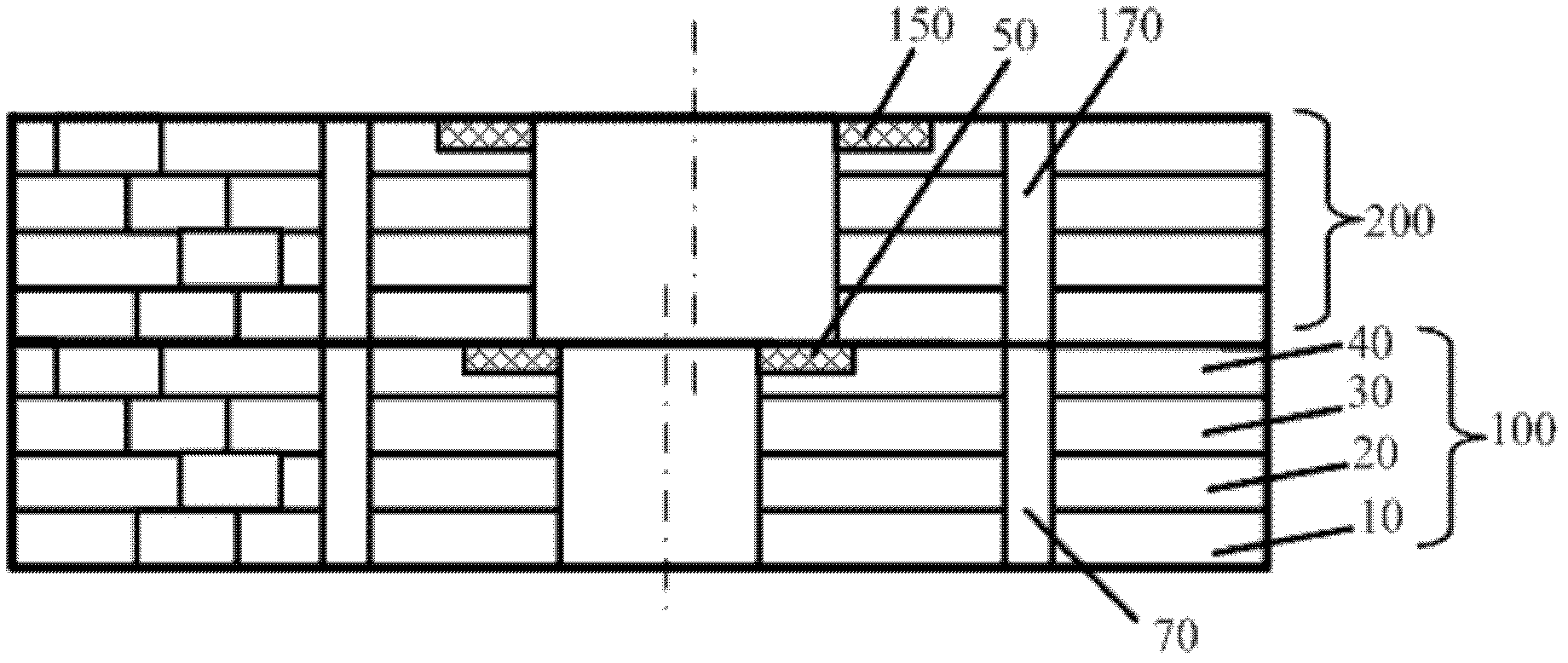

[0031] As mentioned in the background art, there are problems in the existing PCB substrate packaging method, resulting in poor alignment accuracy at specific positions of the PCB substrate. The inventors of the embodiments of the present invention found after research that the alignment accuracy of a certain single-layer board among the multi-layer boards of the PCB substrate is often required to be relatively high. Fingers, and if the gold fingers cannot be aligned accurately, it will affect the transmission of signals from the gold fingers to the outside world, and the topmost single-layer board has high requirements for alignment accuracy. Although the overall accuracy of the multi-layer board obtained after drilling with the existing method is improved, when multiple multi-layer boards are stacked, the alignment accuracy of the gold fingers is reduced, which affects the transmission of signals.

[0032] Please refer to image 3 , taking two multi-layer boards as an examp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com