Device for determining and/or monitoring a prescribed fill level

An equipment and material level technology, which is applied to the equipment field of at least one material level, can solve the problems of unknown measuring devices, defective measurement results, etc., and achieve the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

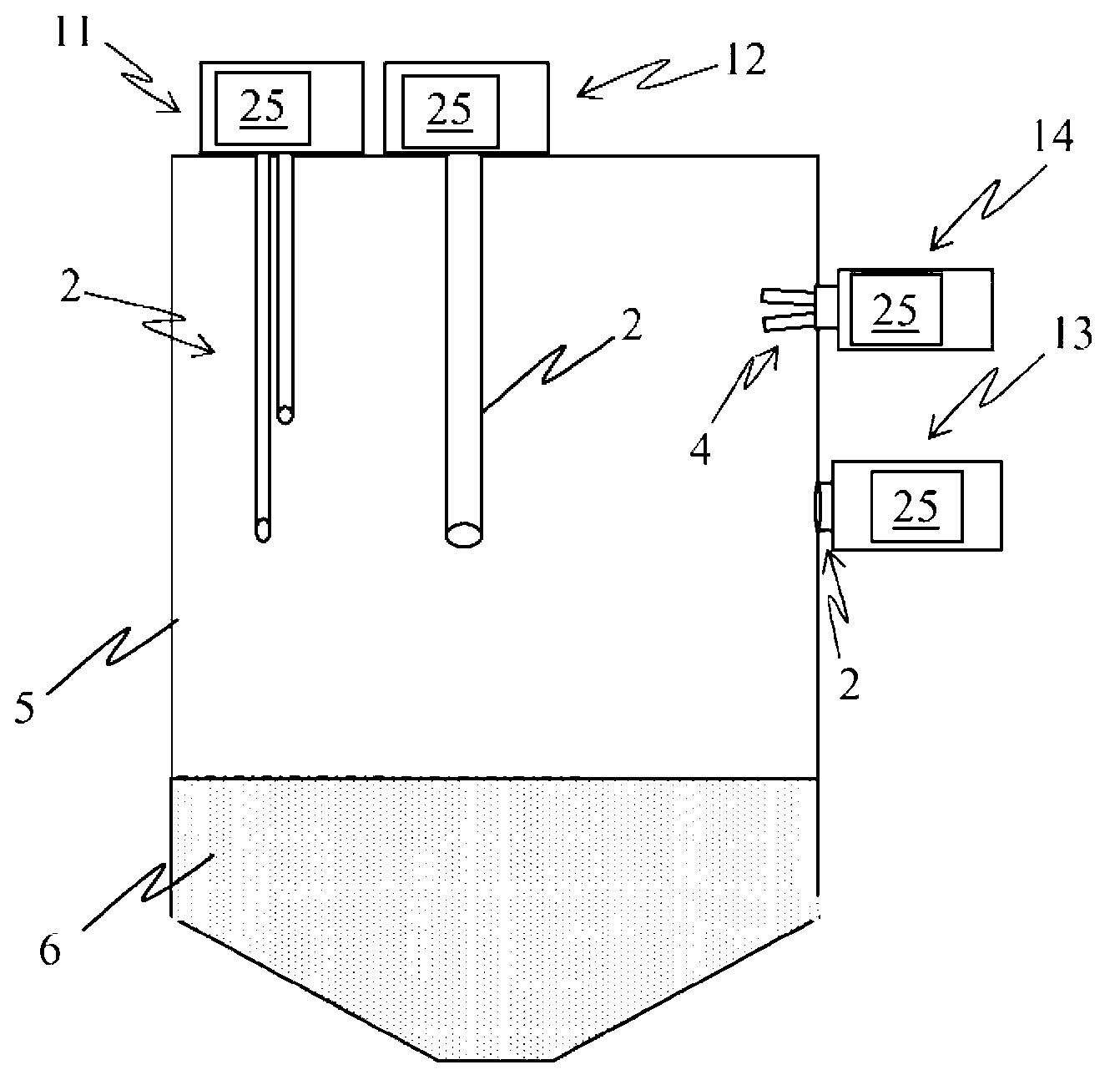

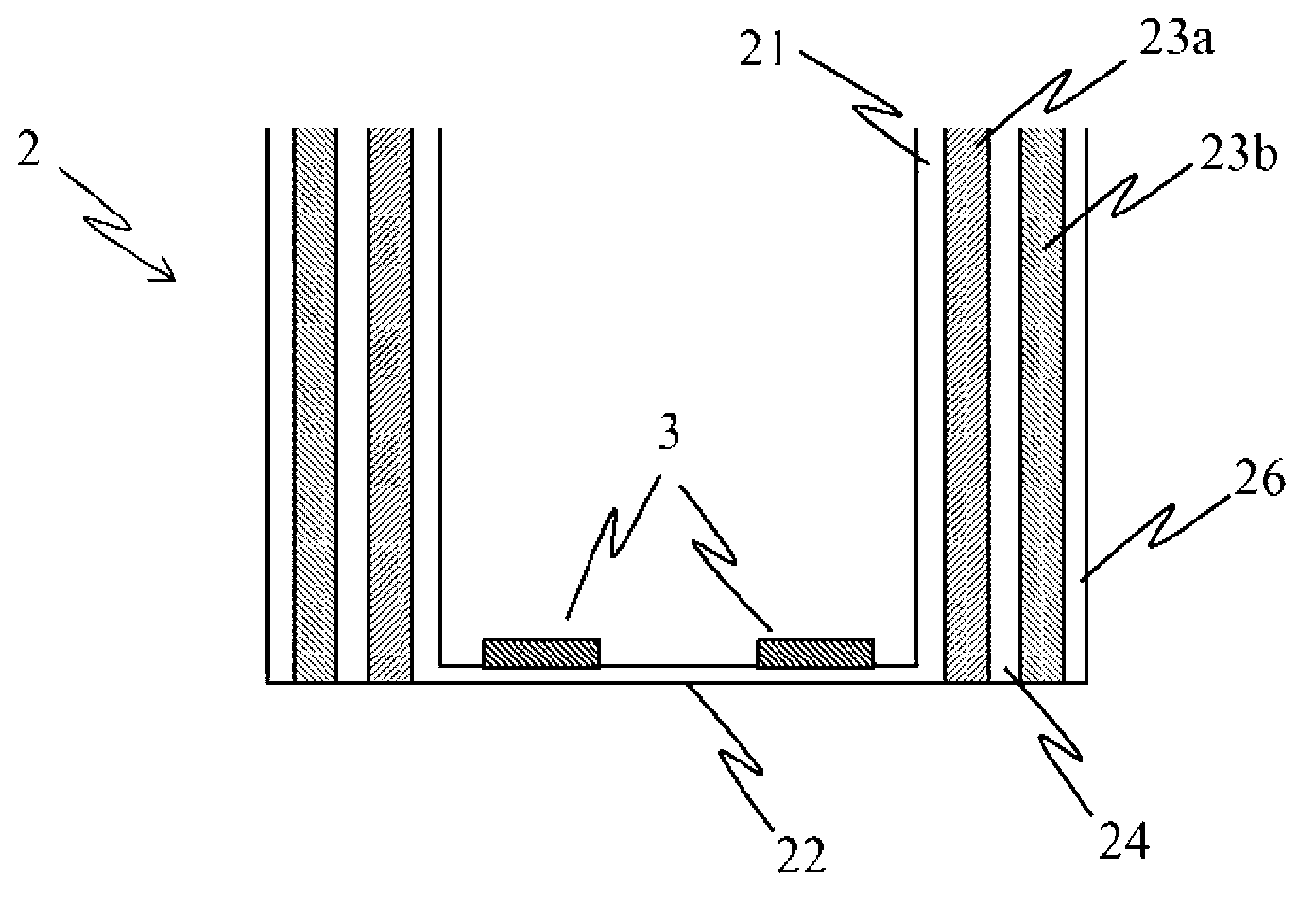

[0017] figure 1 A container 5 is shown which is partially filled with a liquid medium 6 and has four different measuring devices for monitoring the filling level. Shown therein are a conductivity sensor 11 for capacitive or conductive measurement, a capacitive sensor 12 , a flush sensor 13 , and a vibrating fork 14 representing an electronic vibratory measuring device. In each case, the measuring devices 11 , 12 have a detection unit 2 which protrudes from above inwardly into the container 5 . Electronic components such as the control / evaluation unit 25 are housed in the sensor head which remains outside the container. The detection unit 2 of the flush-mounted sensor 13 installed laterally in the container ends flush with the wall of the container 5 , so that only the surface emerges from the interior of the container 5 . Each detection unit 2 has one or more electrodes and is used for capacitive or conductive filling level recording. Such measuring devices are known from t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com