Cold aerosol fire-extinguishing method for large floating roof storage tank

A cold aerosol and oil storage tank technology, which is applied in fire rescue and other fields, can solve the problems of large floating roof storage tanks with large storage capacity, heavy losses, and high risk, and achieve a simple and practical structure, a small number of uses, and high safety performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

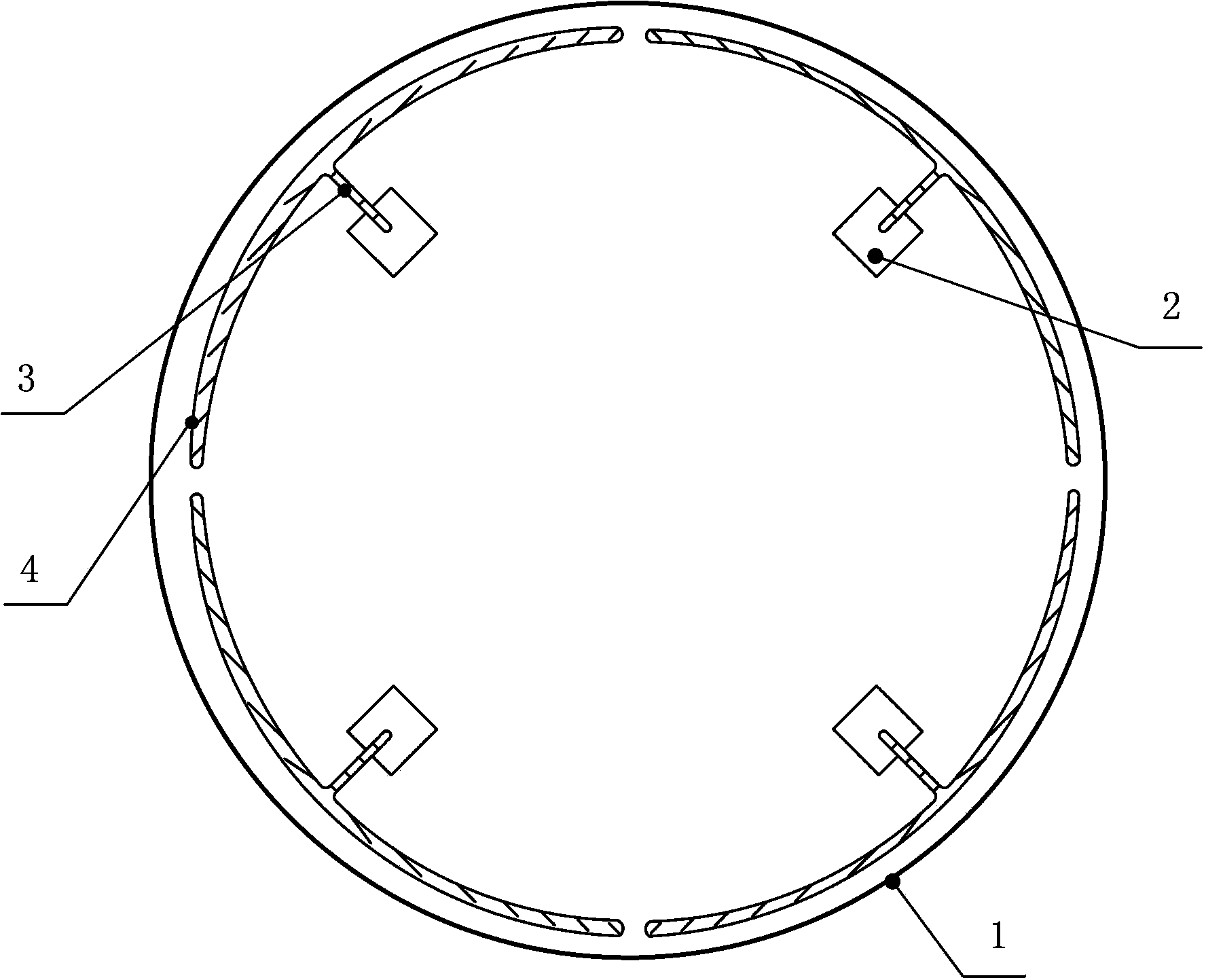

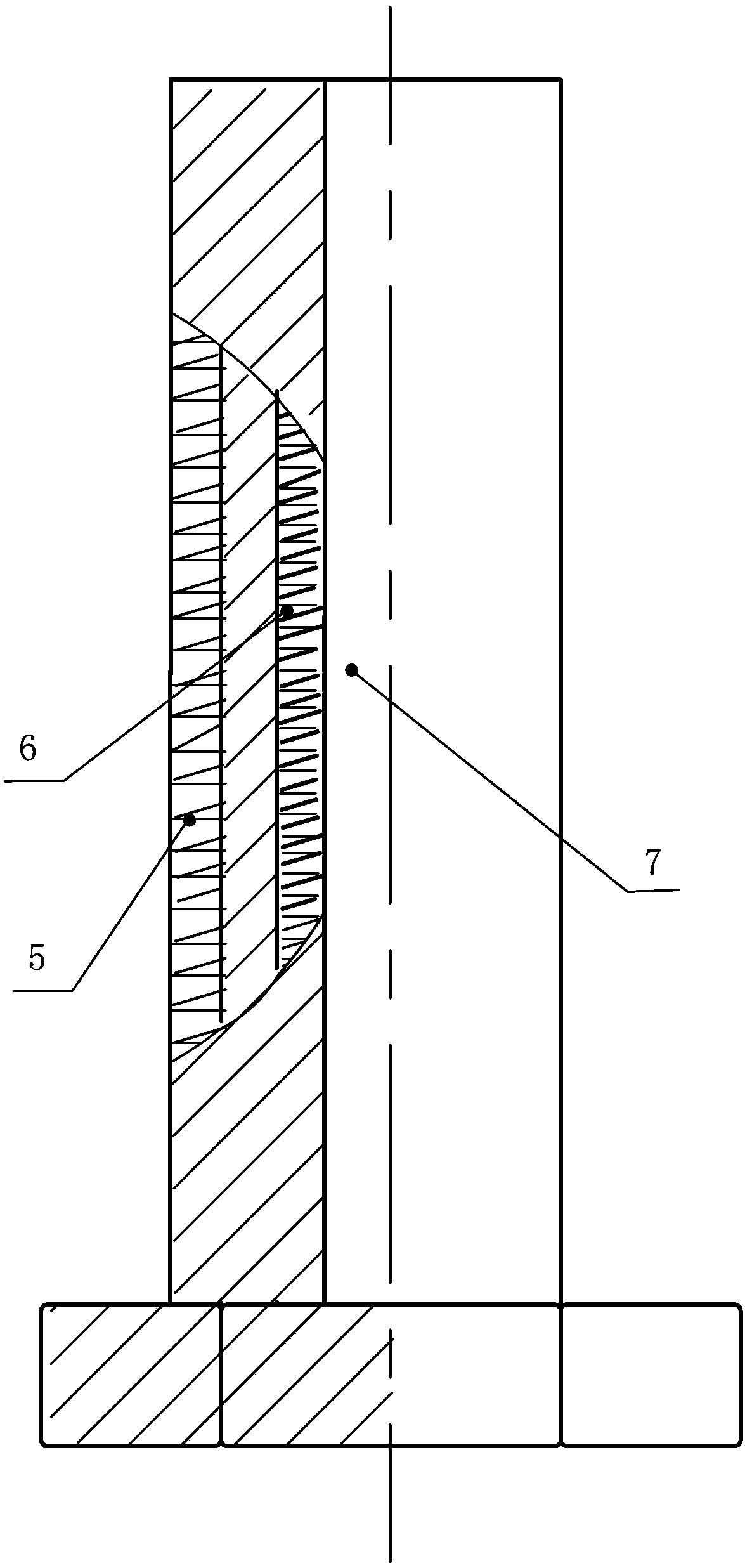

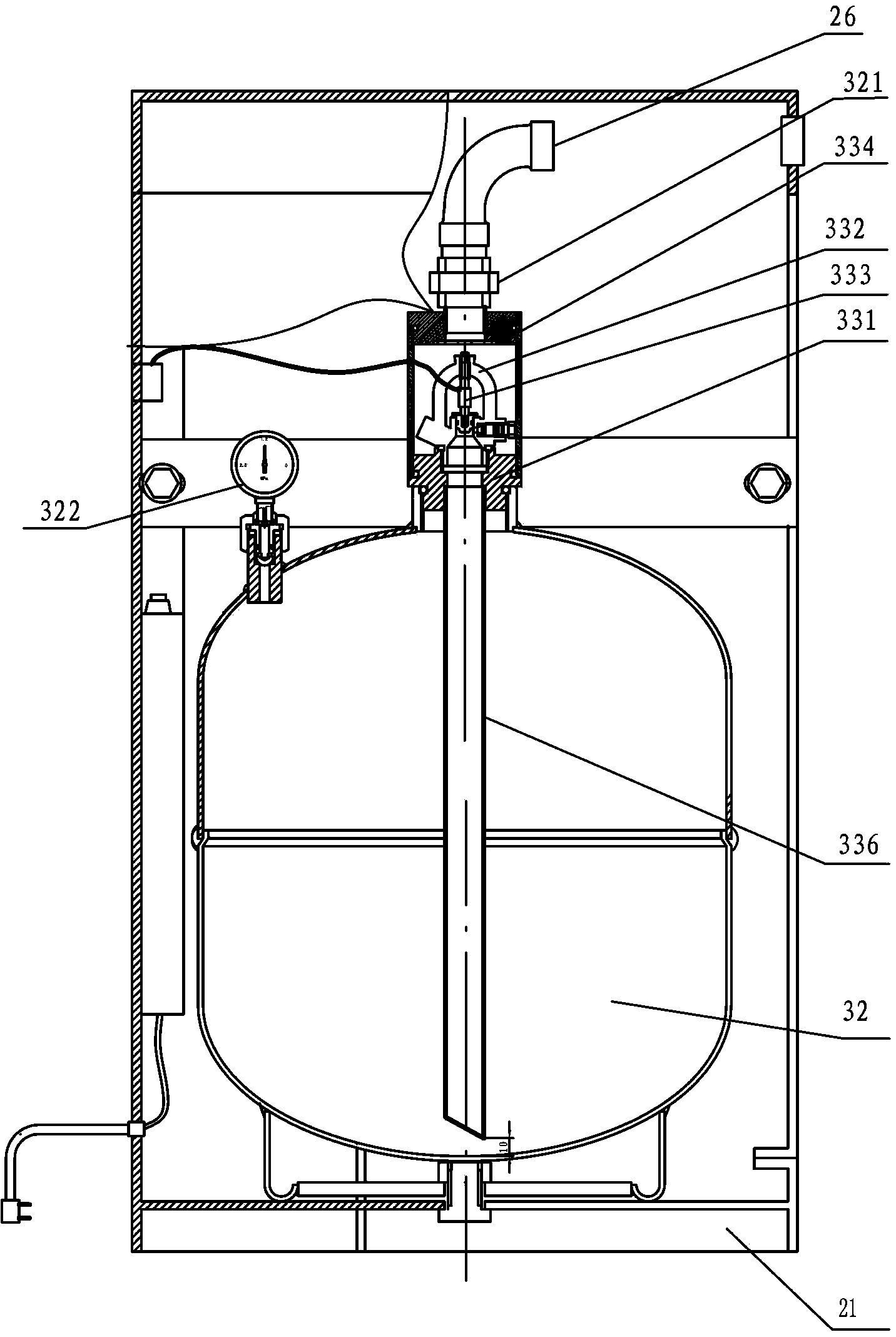

[0057] The 50,000 m standard floating roof oil storage tank is 19.5m high, 60m in diameter, and 188.4m in circumference. In this example, a fiber grating automatic fire detection and alarm system is set up. The fiber grating temperature sensing fire detection signal processor is placed in the monitoring station, and the signal processor and the fiber grating temperature sensor are connected by a 24-core armored optical cable. The fiber grating temperature-sensitive fire detector is installed on the outer edge of the secondary sealing ring of the floating plate on the top of the tank along with the detection optical cable, and the distance is about 6.0m. Two sensor chains are used on the top floating plate of the oil tank, and each sensor chain contains 16 fiber grating temperature sensors. The laying section of the optical cable in the tank is protected by a metal hose with a diameter of DN40 from the top of the tank to the floating plate in the tank. The upper end of the meta...

Embodiment 2

[0062] The 100,000 m standard floating roof oil storage tank is 21.8m high, 80m in diameter, and 251.2m in circumference. In this example, a fiber grating automatic fire detection and alarm system is installed. The fiber grating temperature sensing fire detection signal processor is placed in the monitoring station, and the signal processor and the fiber grating temperature sensor are connected by a 24-core armored optical cable. The fiber grating temperature-sensitive fire detector is installed on the top of the tank along with the detection optical cable, and the outer edge of the secondary sealing ring, with a distance of about 6.0m. Three sensor chains are used on the oil tank filling floating plate, and each sensor chain contains 15 fiber grating temperature sensors. The laying section of the optical cable in the tank is protected by a metal hose with a diameter of DN40 from the top of the tank to the floating plate in the tank. The upper end of the metal hose is fixed on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com