Injection molding machine with combination plate of temperature adjustment pipe

A technology of temperature adjustment and combination plate, which is applied in the field of injection molding machines, can solve the problems of easy escape of heat, large temperature difference, large contact area of the disk surface, etc., and achieve the effect of uniform temperature distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

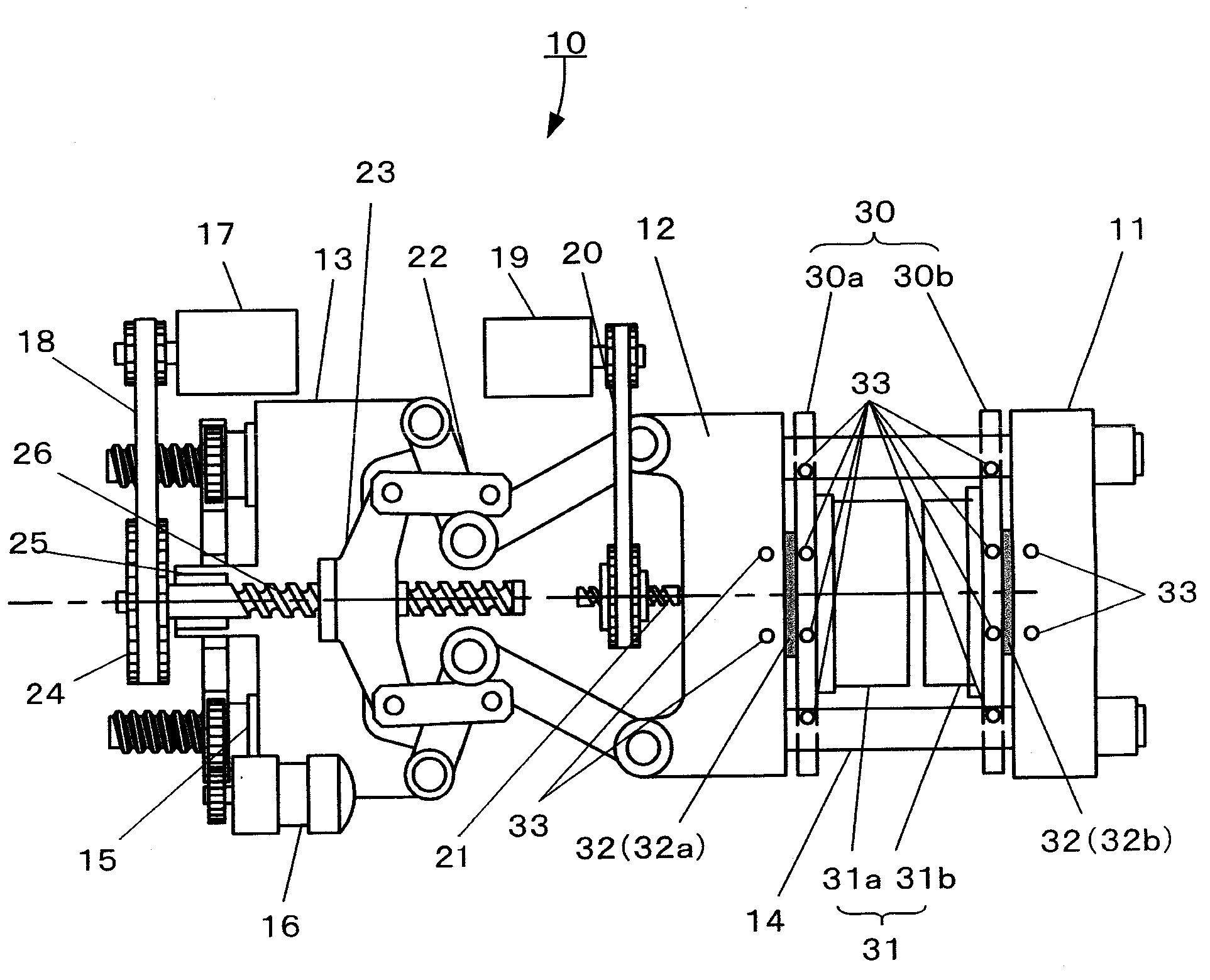

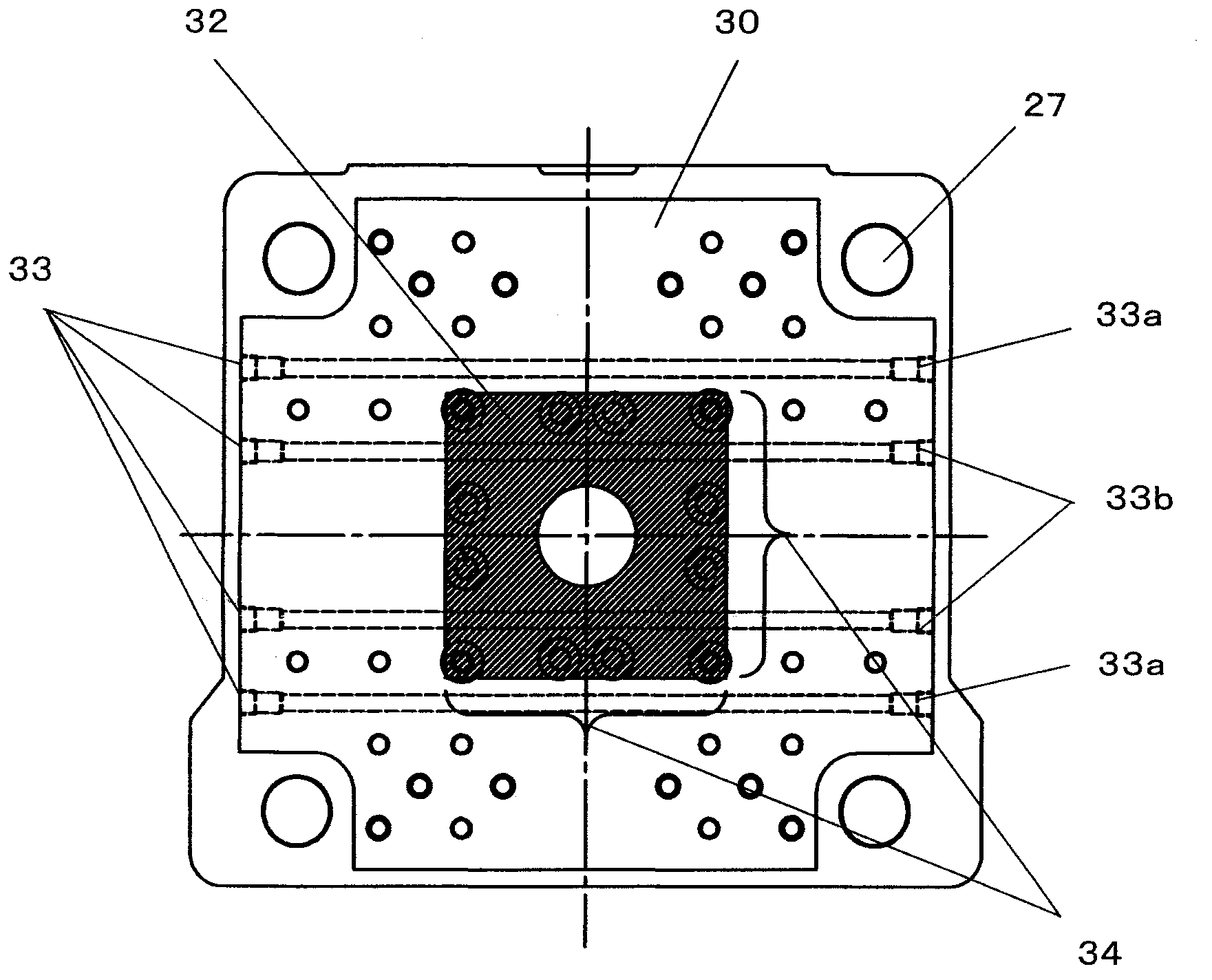

[0012] use figure 1 , an embodiment of the injection molding machine including the coupling plate with the piping for temperature adjustment of the present invention will be described.

[0013] The injection molding machine is generally composed of an injection device (not shown) and a mold clamping device 10 . The injection device is composed of a cylinder, a screw provided in the cylinder so as to be drivable in a rotational direction and an axial direction, a driving unit for driving the screw in a rotational direction and an axial direction, and the like. The mold clamping device 10 includes: a fixed plate 11 fixed on the machine base (not shown); a mold clamping plate 13 spaced apart from the fixed plate 11 and arranged on the machine base in an axially movable manner; Four connecting rods 14 between the fixed disc 11 and the mold clamping disc 13; the movable disc 12 guided by the four connecting rods 14 in the direction of its axis; the movable disc 12 is driven in the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap