Sheeting machine with floor sweeping function

A tablet press, functional technology, applied in the direction of material forming presses, presses, manufacturing tools, etc., can solve the problems of reducing the cleanliness of the processing operation room, complex structure, raw material pollution, etc., to save manpower and simple structure , low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

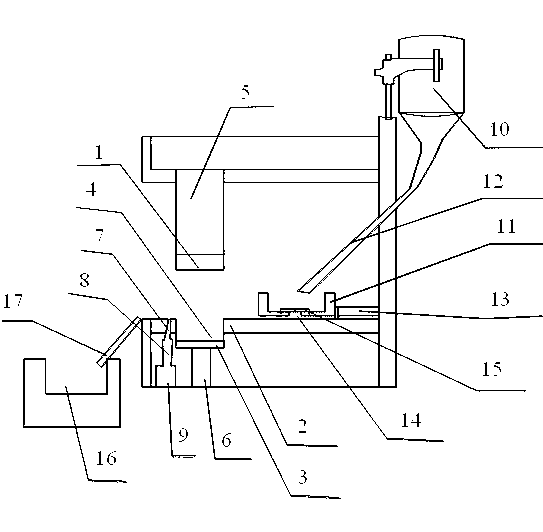

[0021] like figure 1 As shown, the tablet press with sweeping function comprises an upper die 1, a middle die 2 and a lower die 3 arranged from top to bottom; the middle die is provided with die holes 4, and the upper die and the lower die are The diameters are equal to the diameter of the die hole; and the upper punch, the die hole and the lower punch are on the same axis; one side of the middle die is provided with a feeding mechanism, and the other side is provided with a powder suction mechanism.

[0022] The upper punch is connected with an upper punch drive mechanism 5 that drives the upper punch to move up and down.

[0023] The lower punch is connected with a lower punch drive mechanism 6 that drives the lower punch to move up and down.

[0024] The powder suction mechanism includes a powder suction nozzle 7, a powder delivery hose 8 and a vacuum cleaner 9. The opening of the powder suction nozzle is arranged on the middle mold, and the other end of the powder suction...

Embodiment 2

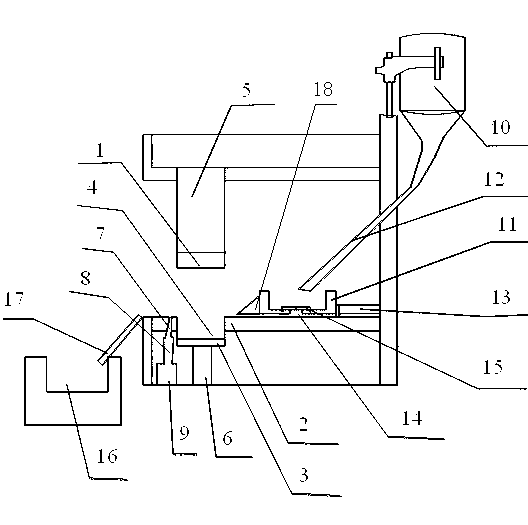

[0029] like figure 2 As shown, the difference between the present embodiment and embodiment 1 is that since the compressed material is generally a chemical and pharmaceutical tablet, the compressed raw material is a powder in a powder state. During punching, part of the medicinal powder must overflow, so the medicinal powder is generally pressed and stuck on the upper surface of the lower die 3 during stamping, and if it goes on for a long time, it will have an impact on the later pressing effect. Therefore, it is necessary to carry out bottom hanging treatment on the upper surface of the lower die 3 . Therefore, in this embodiment, a bottom sweeping blade 18 is connected to the side of the feeding box 11 close to the powder suction mechanism. Like this, when the upper surface of the lower die 3 is flush with the upper surface of the middle mold 2, under the promotion of the material box pushing mechanism 13, the feeding box 11 drives the sweeping blade 18 to move toward the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com