Vehicle-mounted tool cabinet for motor vehicles

A vehicle-mounted tool and motor vehicle technology, applied in vehicle parts, transportation and packaging, etc., can solve the problems of inconvenient installation and operation, easy damage to the original vehicle, unable to meet the requirements of quick installation and disassembly, etc., to save interior space and facilitate maintenance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

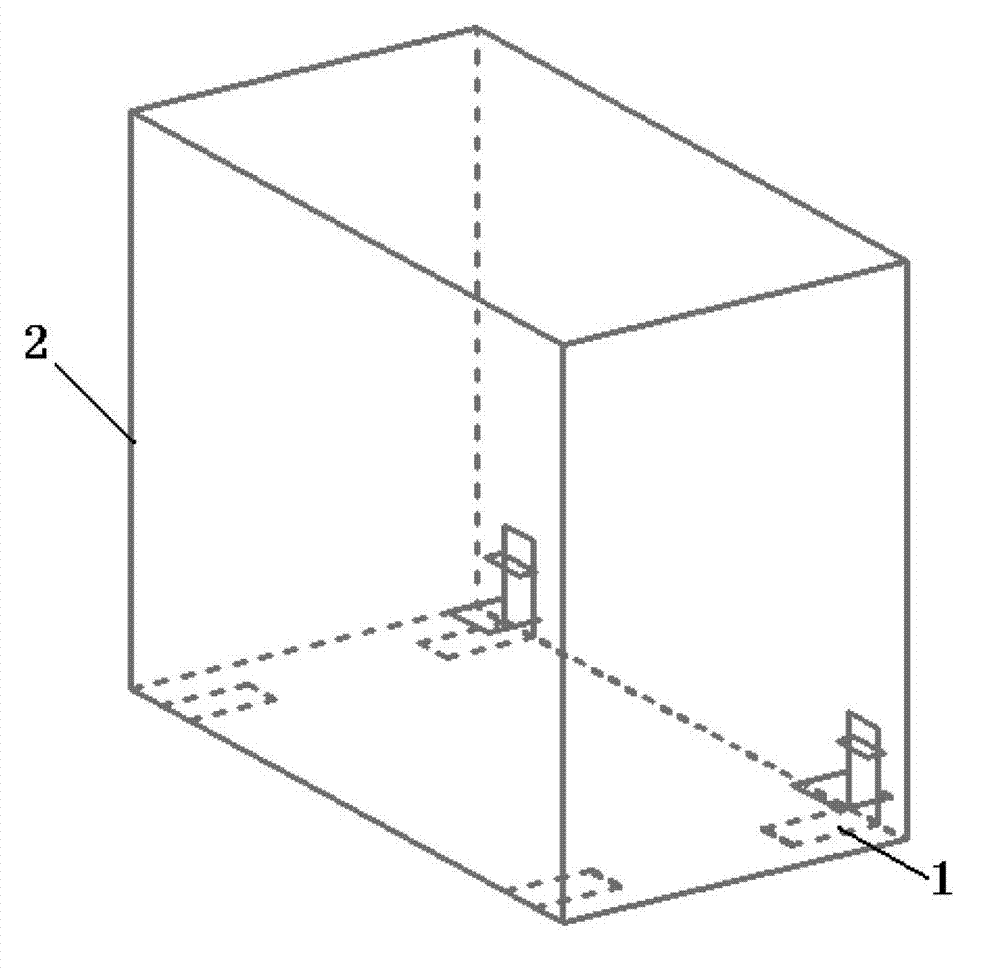

[0020] The technical solution provided by the present invention is the vehicle-mounted tool cabinet, the tool cabinet 2 is provided with a mounting hole 1 that can be quickly installed and / or disassembled, and the mounting hole 1 is arranged at the bottom of the tool cabinet 2 at the four corners. The tool cabinet 2 is fixedly connected with the vehicle body through a safety buckle, and the safety buckle includes an upper buckle body and a lower buckle body. On the body of the motor vehicle, corresponding to the positions of the four corners at the bottom of the tool cabinet 2, a lower button body is provided. The lower button body is connected with the vehicle body by riveting. The installation hole 1 inside the tool cabinet 2 is provided with an upper button body.

[0021] The upper button body is fixedly connected with the tool cabinet 2 by welding. The upper button body is connected to the lower button body through buckles.

[0022] According to the principle that the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com