Corner fitting of container

A technology for containers and corner fittings, applied in the field of container corner fittings and connectors, can solve the problems of easy danger, inability to perform lateral fixation, insufficient thickness of the lifting holes for corner fittings, etc., and achieves the effect of a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

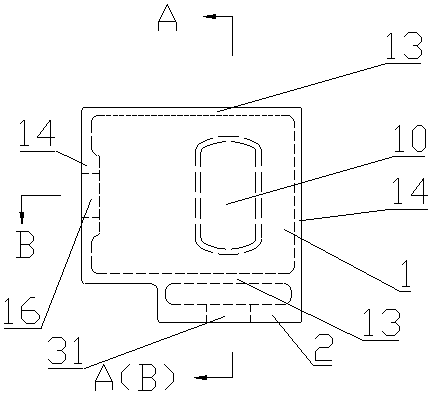

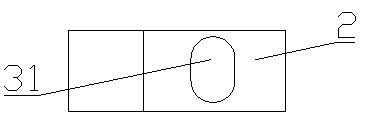

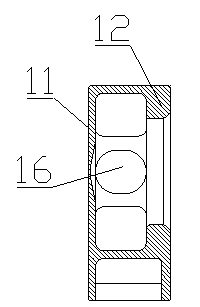

[0041] like Figure 1 to Figure 16 As shown, a container corner fitting of the present invention includes a main body 1 provided with a hoisting hole 10, and a protrusion 2 provided with a fixing structure for fixing a lateral fixing device; the main body 1 is mainly composed of a top surface 11, a bottom surface 12 A pair of end surfaces 13 and a pair of side surfaces 14 are enclosed and formed. The main body 1 is provided with a cavity 15 for accommodating the twist lock; the protrusion 2 is provided on one end surface 13 of the main body 1 .

[0042] The principle of the above technical solution is that, through the extra protruding part 2, there is no conflict between the fixing structure for fixing the lateral fixing device and the cavity 15 for accommodating the twist lock, so as not to af...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com