Speed reducer of mining winch

A technology of speed reducer and winch, which is applied in hoisting device, spring mechanism, etc., can solve the problems of low transmission efficiency of reducer, long overall length of winch, high maintenance and repair cost, and achieve light weight, low maintenance and repair cost, Good braking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

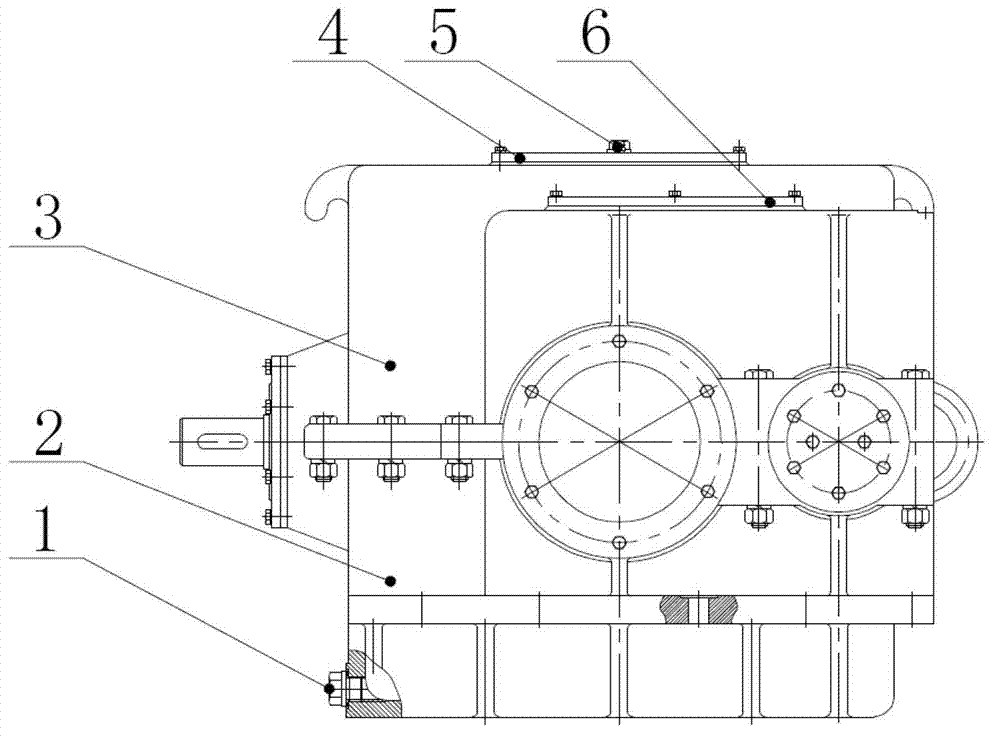

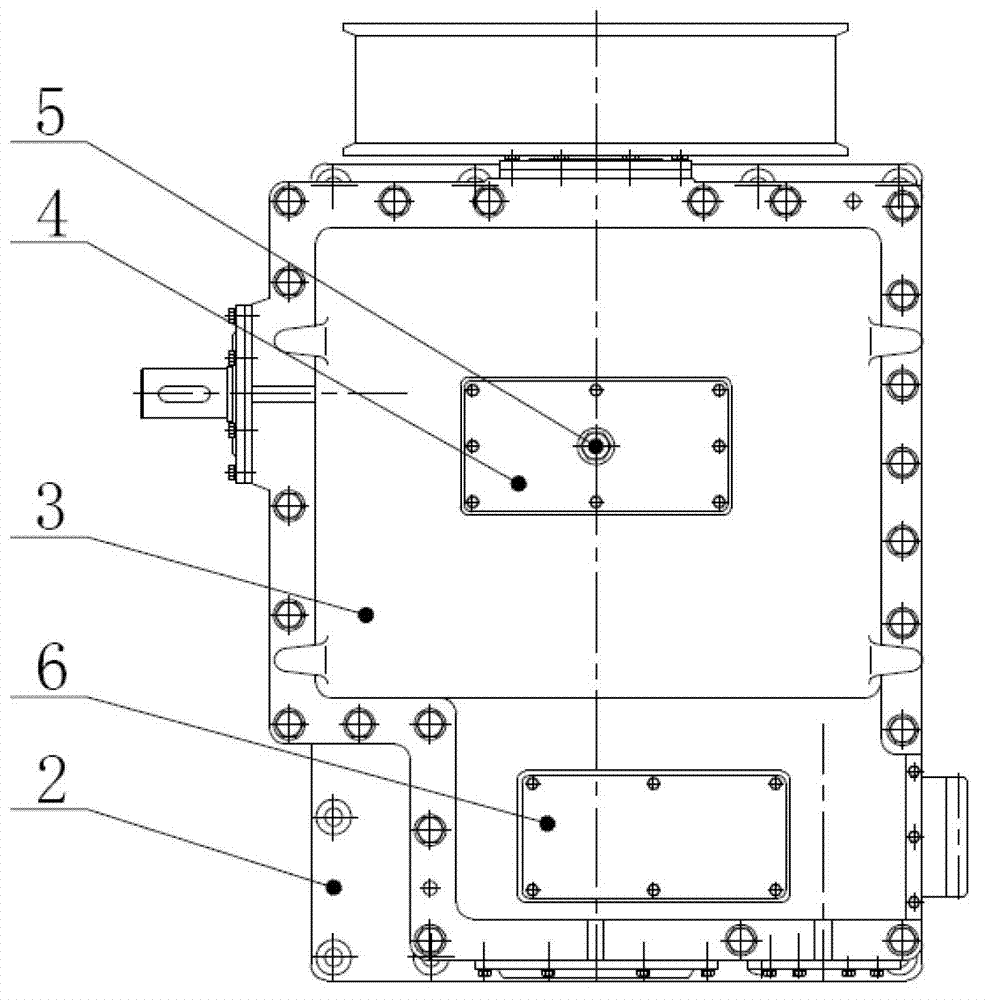

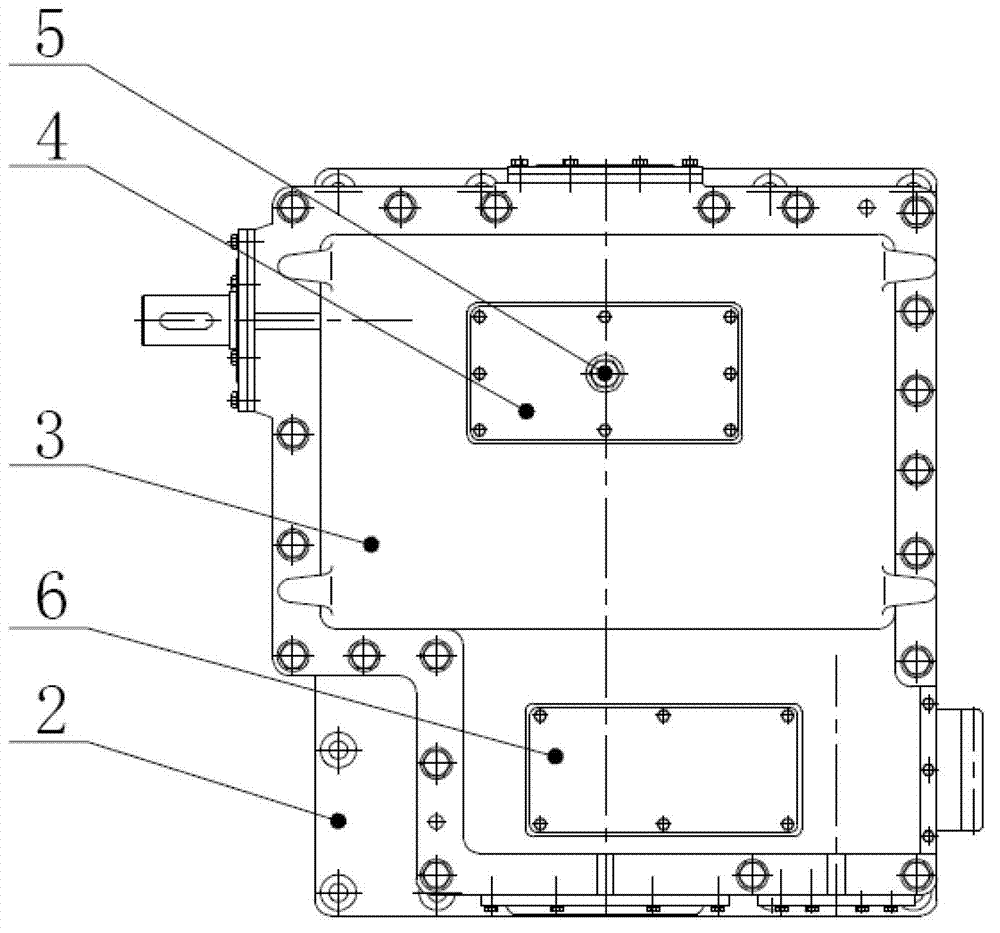

[0020] Such as figure 1 , 2 and Figure 4 Shown: a mining winch reducer, including a lower box 1, an upper box 3, an input shaft assembly, a flat key shaft assembly, a planet carrier assembly and a bridge shaft assembly, the input shaft assembly includes an input shaft 7, a transparent Cover 8 and sleeve cup 9, wherein one end of the input shaft 7 is processed with a small bevel gear that meshes with the bevel gear on the large bevel gear 10 and the inner ring gear 16, and the other end is processed with a flat keyway to connect with the coupling through a flat key , the flat key shaft assembly includes a flat key shaft 11, a large bevel gear 10, an inner ring gear 16, a central gear 18, a sleeve cup 12, a transparent cover 13, a brake wheel 14 and a stuffy cover 15, 17, a large bevel gear 10, a center The gear 18 and the brake wheel 14 are respectively installed on the flat key shaft 11 through a flat key, and the inner ring gear 16 is assembled on the flat key shaft 11 thr...

Embodiment 2

[0022] Such as figure 1 , 3 and Figure 5 As shown: the reducer is mainly composed of the lower box body 1, the upper box body 3, the input shaft assembly, the flat key shaft assembly, the planet carrier assembly and the bridge shaft assembly, which is basically the same as the first embodiment, except that no brake wheel is provided 14, the flat key shaft 11 is shortened and does not stretch out the casing, the original transparent cover 13 is changed into a stuffy cover 31, and a stuffy cover 32 is added at the flat key shaft 11 ends.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com