Differential mechanism of transmission system of automobile

A transmission system and differential technology, applied in the direction of transmission, vehicle parts, differential transmission, etc., can solve the problems of input gear wear, large input gear size, etc., to prolong service life, reduce size, improve height Effect of variable load and shock load capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

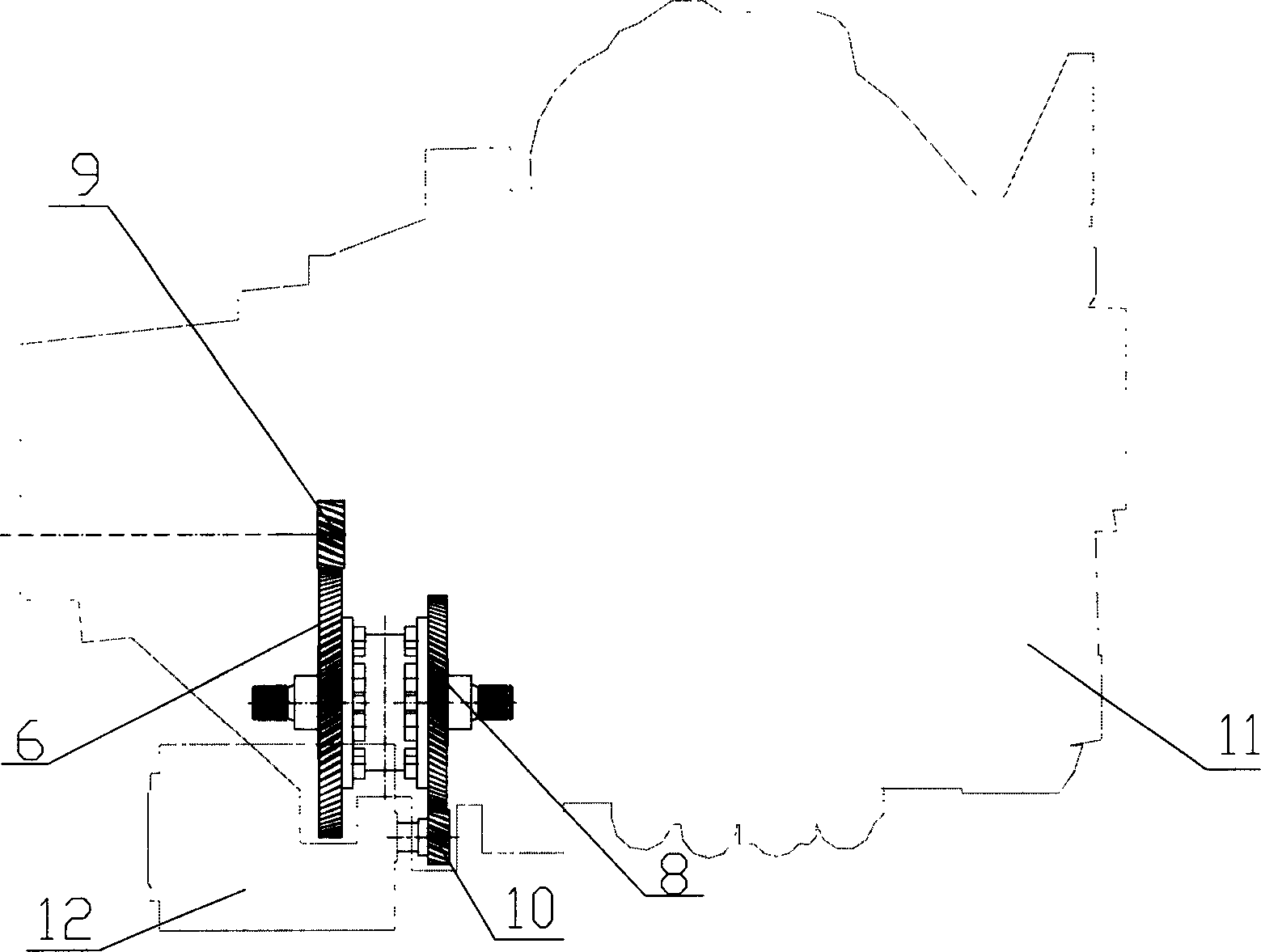

[0010] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

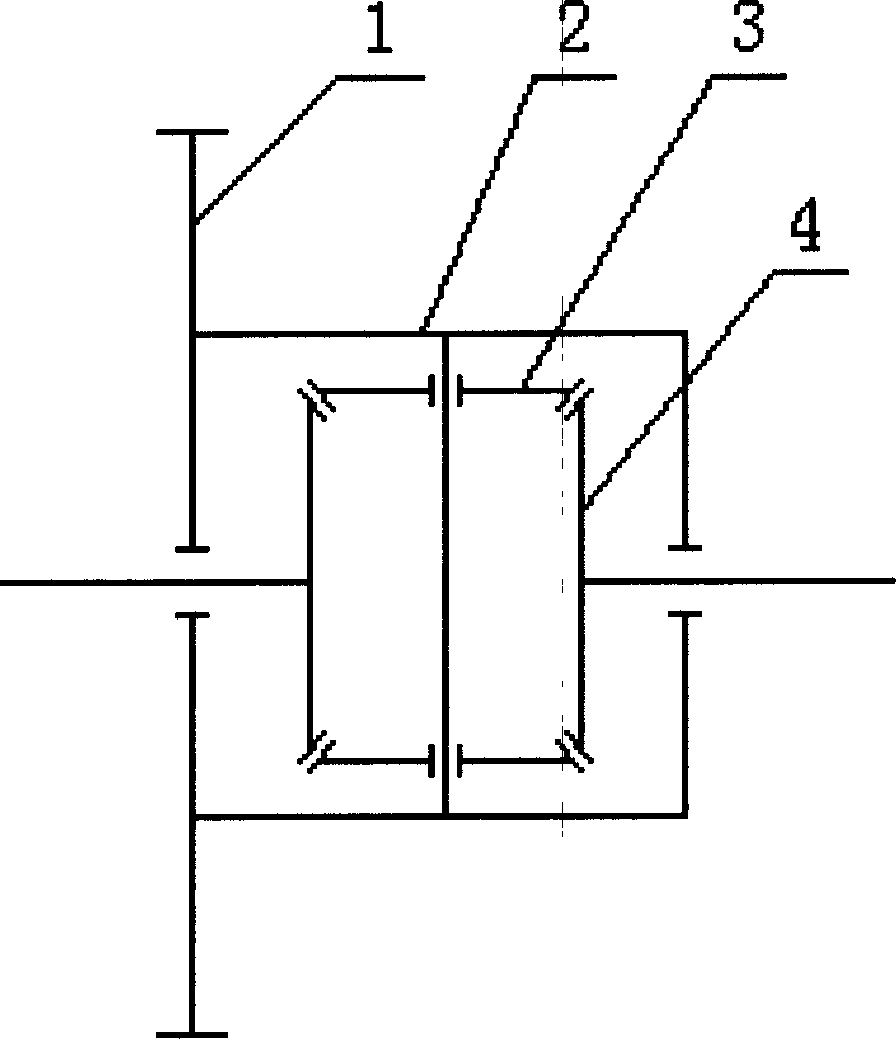

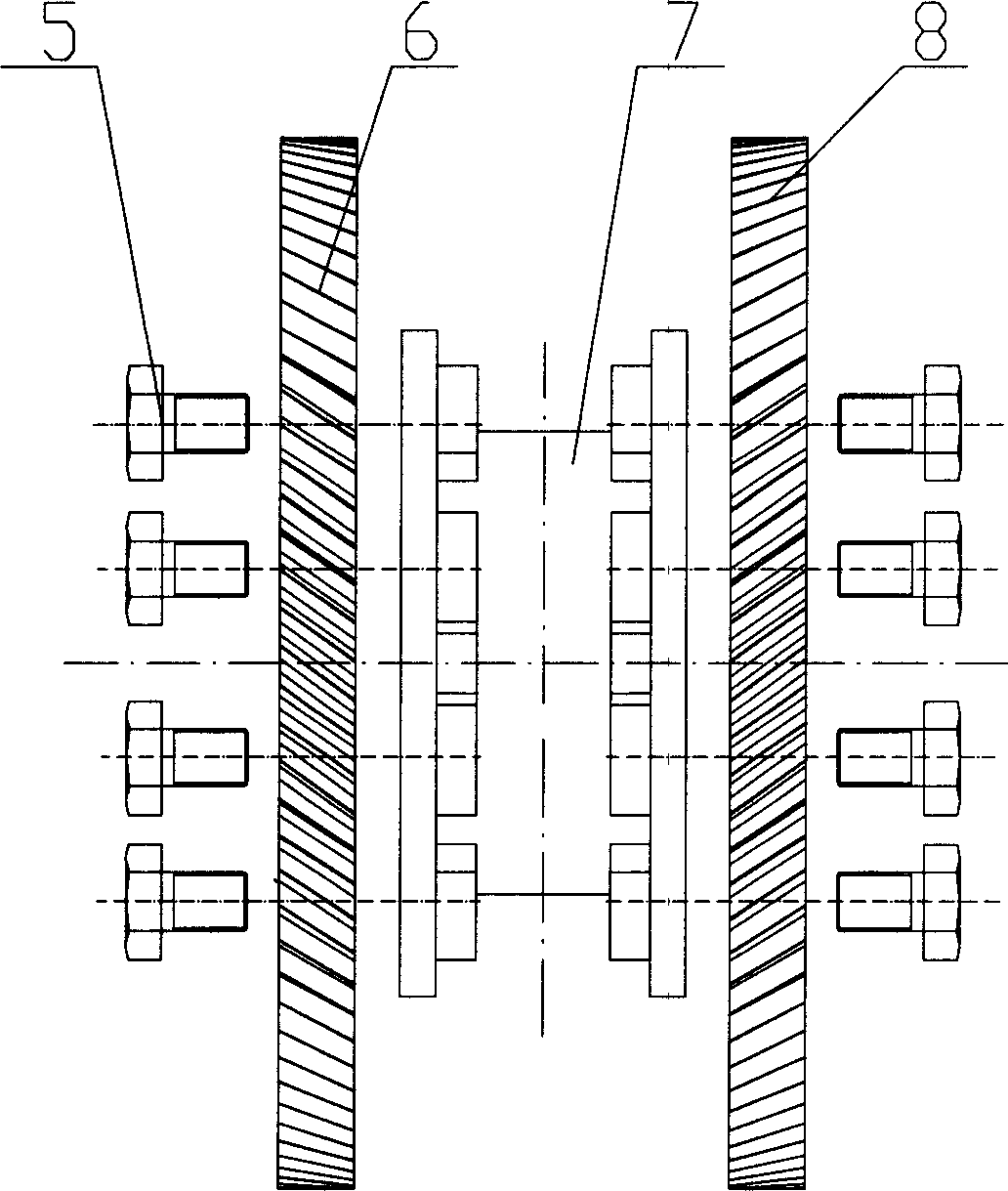

[0011] Such as figure 2 As shown, the differential in the vehicle drive train provided by the present invention includes a planetary assembly 7, the outer shell of the planetary assembly 7 has input gears, and there are multiple input gears, preferably 2-4.

[0012] Wherein, planetary assembly 7 can adopt traditional planetary assembly, also can adopt the planetary assembly disclosed in CN 2644210Y, for example, this planetary assembly can include planetary carrier, planetary wheel and output gear (not shown in the figure) .

[0013] Preferably, the outer shell of the planetary assembly 7 has two input gears 6 , 8 respectively arranged on opposite sides of the outer shell of the planetary assembly 7 . By connecting one input gear 6 to the vehicle engine and the other input gear 8 to the electric motor, a hybrid combined drive can b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com