Front loading type pile turning machine

A compost turner and front-mounted technology, which is applied in the direction of organic fertilizer, fertilization device, organic fertilizer preparation, etc., can solve the problem that the reaction force of the front-type compost turner is not solved, the compost turner has no folding function, and it is inconvenient to grow Problems such as distance transitions, etc., to achieve the effect of facilitating long-distance transitions, balancing reaction forces, and improving operational performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

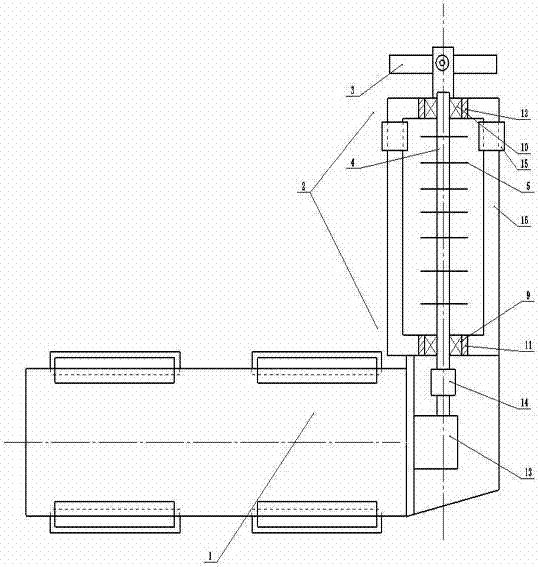

[0020] figure 1 It is a schematic diagram of the layout of each component of the front-end compost turner. The main part of the compost turner is the rotor system, which includes the compost turning device 2, the power input device 13, the torque clutch device 14, the terminal walking device 3, the balance device and the folding device. The compost turning device 2 is fixedly connected with the traction device 1. The traction device 1 in the embodiment is a four-wheel locomotive.

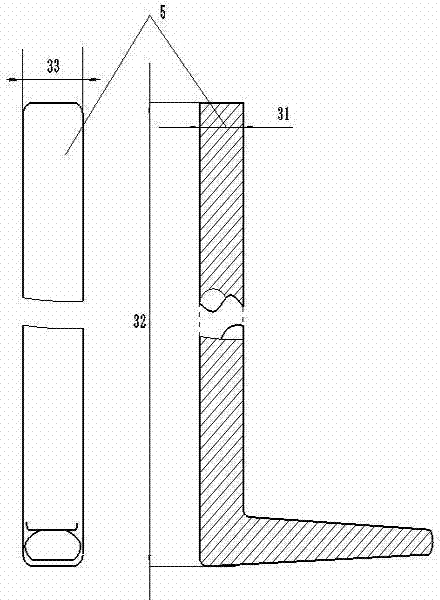

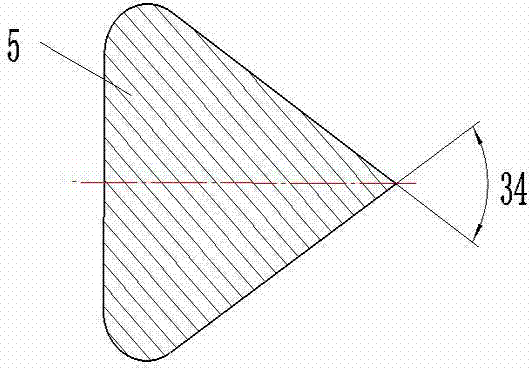

[0021] The turning device 2 is a detachable structure, which is divided into a proximal end and a distal end. The proximal end is connected to the upper traction device 1, and the far end is equipped with a terminal walking device 3. The blades 5 are distributed along the axial direction on the outside to determine the type and distribution of the blades 5. For straw or livestock manure, the blades 5 are generally divided into blade a6, blade b7, and blade c8 according to different sizes. The rotar...

Embodiment 2

[0027] The difference between Embodiment 2 and Embodiment 1 is that in Embodiment 2, the function of the folding device is realized by the hydraulic cylinder 35 as Figure 5 shown. Slender rod 39 connects the hinge 38 on the traction device and the hinge 36 on the turning device, hydraulic cylinder 35 is installed on the traction device 1, and the extended end of hydraulic cylinder 35 connects hydraulic cylinder hinge 37, and above-mentioned hydraulic cylinder hinge 37 is fixed on On the slender rod 39 , the angle between the slender rod 39 and the ground is changed by the extension and contraction of the hydraulic cylinder 35 so as to realize the folding of the stack turning device 2 .

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap