High-fluidity and stress-resistance whitening modified polypropylene composite material and preparation method thereof

A technology of anti-stress whitening and composite materials, applied in the field of anti-stress whitening modified polypropylene composite materials, high flow, can solve the problems of stress whitening, affecting the application of automotive trims, easy to scratch, etc., to achieve improved anti-stress Effect of stress whitening properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] specific implementation

[0018] Below in conjunction with embodiment, the present invention is described in further detail.

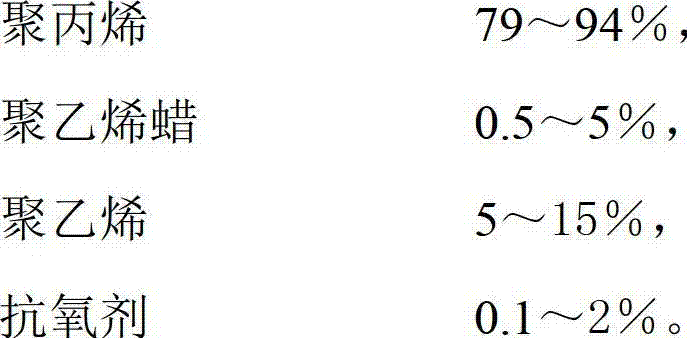

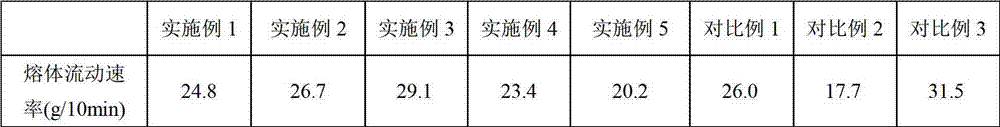

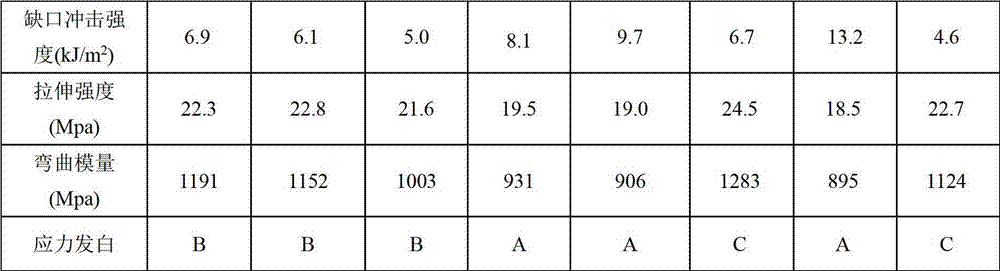

[0019] In the composite material formula of the embodiment and the comparative example, the polypropylene is a copolymerized polypropylene produced by Shanghai Petrochemical Co., Ltd., the trade name is M2600R, and its melt flow rate is 26g / 10min (test condition: 230 ° C × 2.16Kg) Described polyethylene wax is the CERALENE efficient polyethylene wax that Poland EUROCERAS company produces, and trade name is 882, and density is at 0.93g / cm 3 ; The polyethylene mentioned is LLDPE7042 produced by Qilu Petrochemical Company, and its melt index is 2.0g / 10min (test condition: 230°C×2.16Kg). The main antioxidants are DSTP produced by British ICE Company, whose chemical name is octadecyl thiodipropionate, and 3114 produced by Ciba Company, whose chemical name is 3,5-di-tert-butyl-4-hydroxybenzyl diethyl phosphate ester. The auxiliary antioxidant is 16...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt finger | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com