Composite Rubber Packer

A compound glue and packer technology, applied in the directions of sealing/packing, wellbore/well components, earth-moving drilling, etc., can solve the problem of easy sealing failure, etc., so as to reduce the high daily cost and reduce the long-term downhole operation failure. Risk and cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

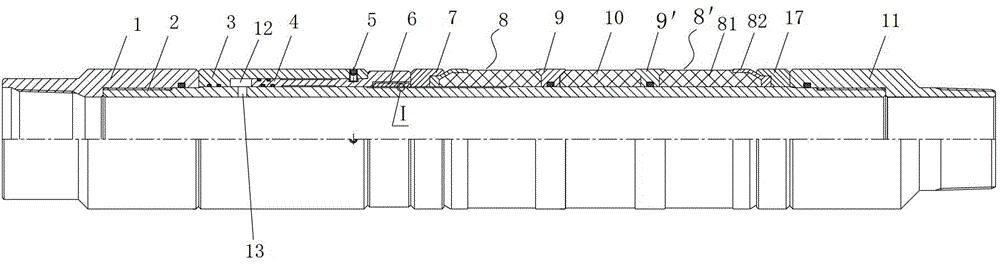

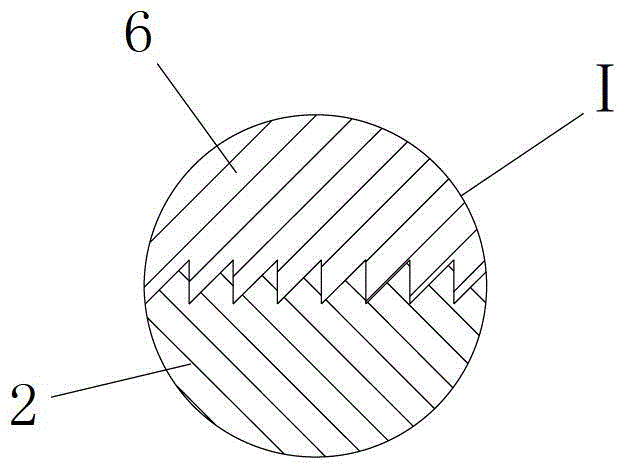

[0017] figure 1 It is a structural sectional view of the composite rubber cartridge packer of the present invention. Such as figure 1 As described above, the composite rubber cartridge packer includes a core pipe 2, an axial compression device and a rubber cartridge assembly sleeved on the core pipe, wherein the rubber cartridge assembly consists of a pressure expansion rubber cylinder 10 and two sides of the pressure expansion rubber cylinder 10 The first liquid-expandable rubber cylinder 8 and the second liquid-expandable rubber cylinder 8' are composed. Wherein, the first liquid-expandable rubber cylinder 8 and the second liquid-expandable rubber cylinder 8' are respectively composed of a vulcanized rubber cylinder 81 and a metal ring 82 sleeved on its end, and are formed by vulca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com