Sheet adhesive machine and its building block type adhesive head

A placement head and placement machine technology, applied in the direction of assembling printed circuits, electrical components, electrical components, etc. with electrical components, can solve the problems of not particularly high control accuracy, complex and precise software and hardware control systems, and placement head assembly Problems such as weight and volume increase, so as to improve the ability to adapt to market challenges and reduce volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] single head embodiment,

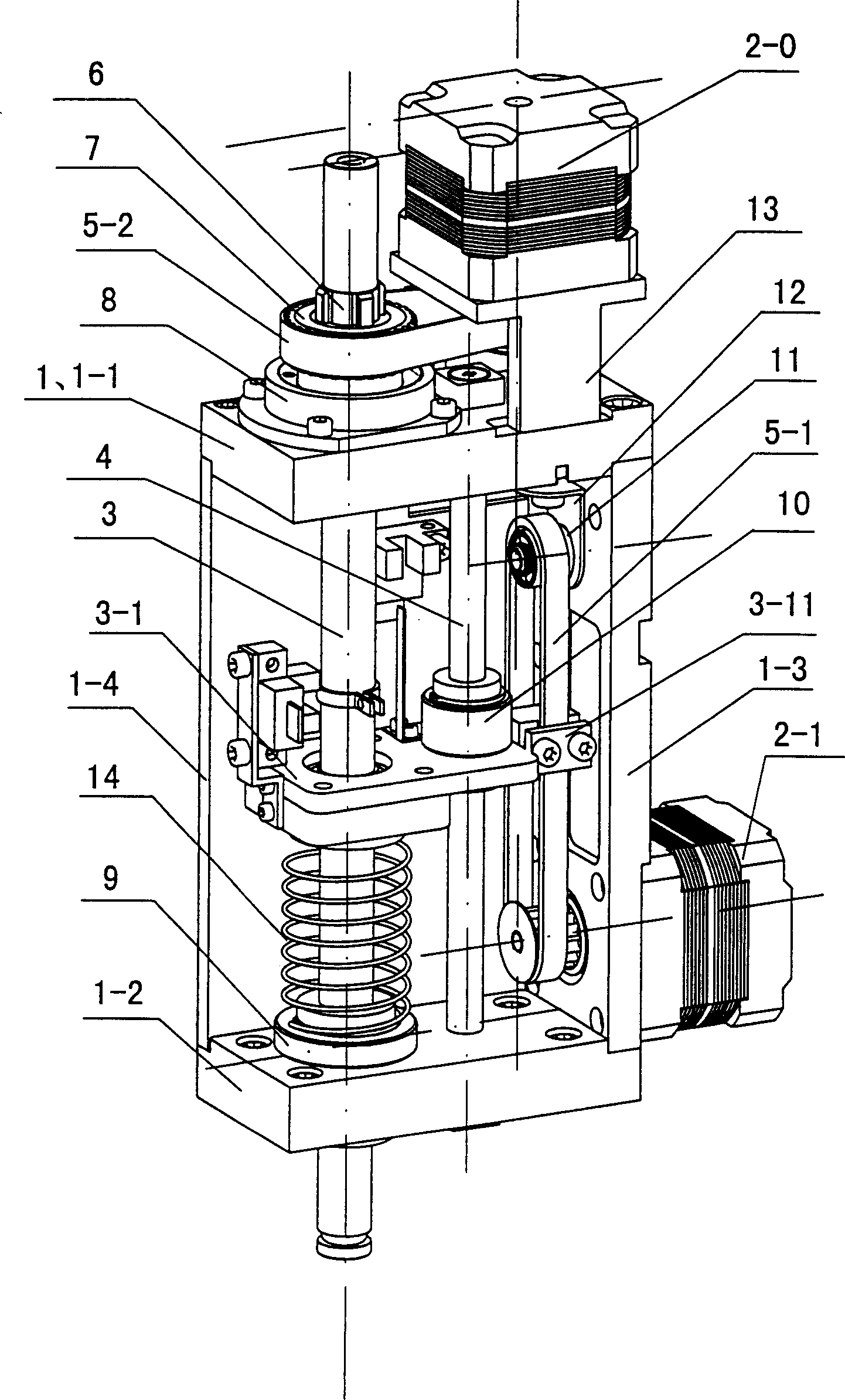

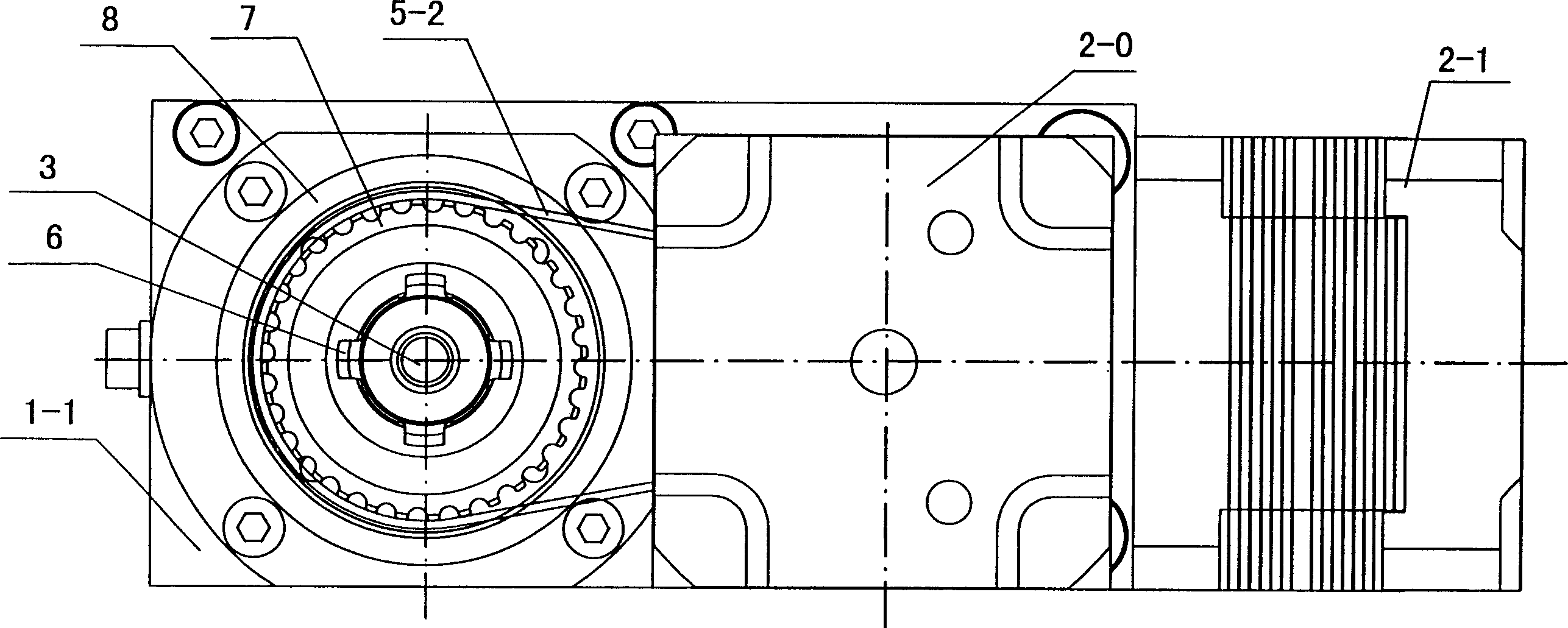

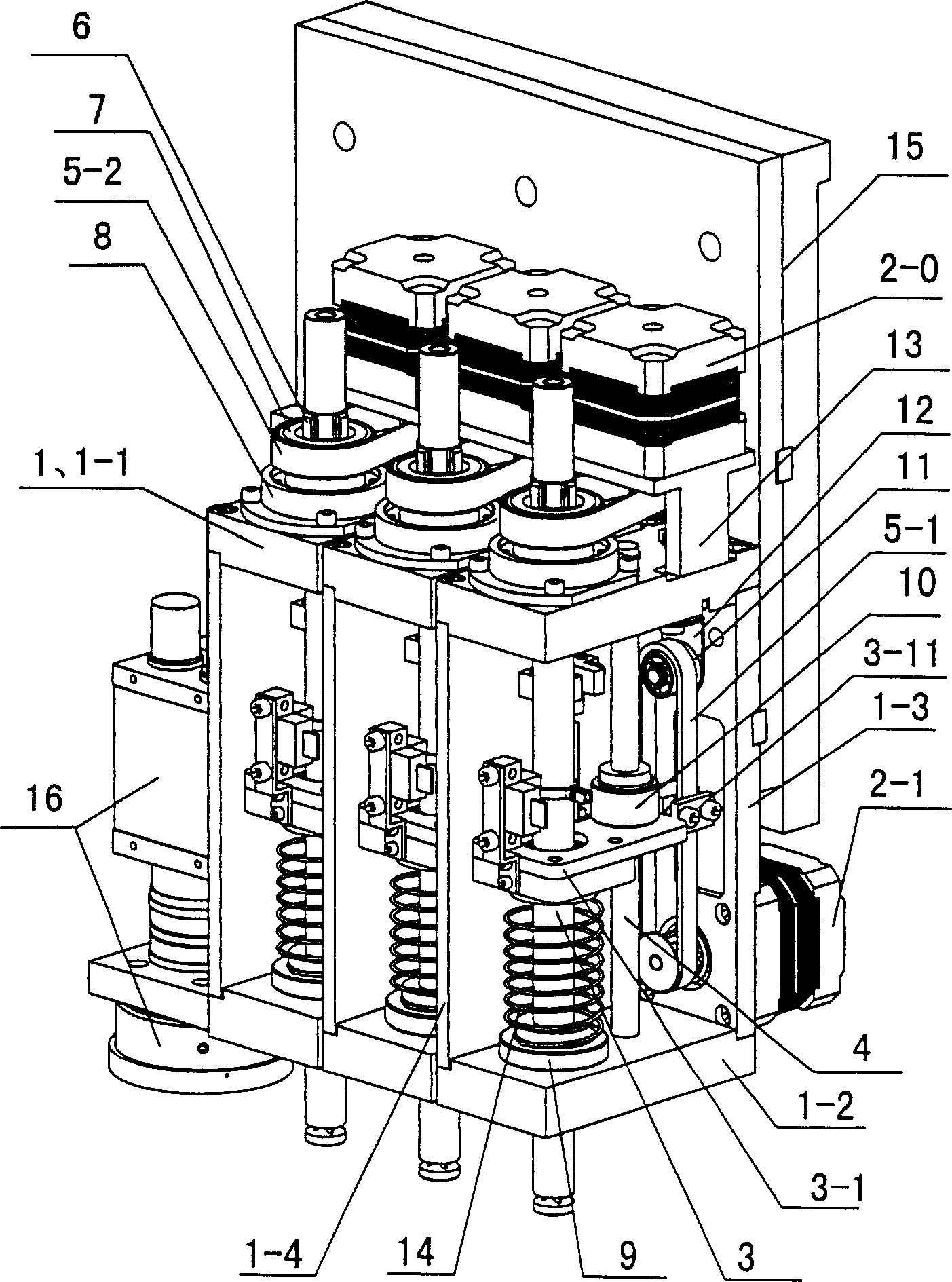

[0024] Such as figure 1 , 2 Shown: the building block mounting head of the chip mounter of the present invention, this mounting head comprises the drive motor that is contained on the frame of mounting head, transmission mechanism, mounting main shaft and suction nozzle, it is characterized in that: described paste Mounting head frame 1 is the frame of " U " shape structure that is constituted by upper shelf plate 1-1, lower shelf plate 1-2 and back plate 1-3, and described placement head frame 1 also includes from side and this U The side plates 1-4 that are connected by the frame; on the basis of the net width of the U-shaped frame 1 excluding the thickness of the side plates 1-4, the U-shaped frame has a virtual vertical bisector;

[0025] There are two drive motors, including a lift drive motor 2-1 and a rotation drive motor 2-0 that drive the mounting spindle to move accordingly, and the drive motors 2-0 and 2-1 are both stepping motors....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com