A kind of non-aqueous phase liquid alkali-free accelerator and preparation method thereof

A non-aqueous liquid and quick-setting agent technology, which is applied in the field of concrete, can solve the problems of loss of coagulation accelerator, product performance degradation, precipitation and precipitation, etc., and achieve the effects of improving deterioration, lowering storage environment requirements, and reducing waste of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

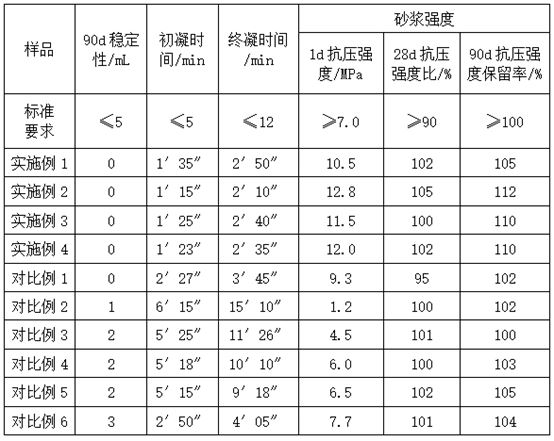

Examples

Embodiment 1

[0037] A method for preparing a non-aqueous liquid alkali-free setting accelerator, comprising the following steps:

[0038] (1) Add 55.6g of pentane to the reaction vessel, turn on the stirring device, control the temperature at 5-10°C, and simultaneously start to feed nitrogen from the bottom of the reaction vessel, add 30g of triethylaluminum to it, until it is mixed with the solvent homogeneously , then add 10 g of dimethyl aluminum hypophosphite, stop feeding nitrogen after the reaction for 2 h, and obtain the modified organic aluminum salt;

[0039] (2) Add the modified organic aluminum salt into the reaction vessel, turn on the stirring device, and add 0.4 g of hydroxymethyl cellulose and 4 g of calcium formate in turn to ensure that each material is stirred evenly before adding the next material. The reaction time is controlled to be 2 hours, and the temperature of the reactant is ensured to be 15-20° C. through temperature control measures throughout the whole process...

Embodiment 2

[0041] A method for preparing a non-aqueous liquid alkali-free setting accelerator, comprising the following steps:

[0042] (1) Add 34.8g of hexane to the reaction vessel, turn on the stirring device, control the temperature at 5-10°C, and simultaneously start to feed nitrogen from the bottom of the reaction vessel, add 45g of tributylaluminum to it, until it is mixed with the solvent uniformly , then add 15 g of aluminum diethyl hypophosphite, stop feeding nitrogen after 2 h of reaction, and obtain modified organoaluminum salt;

[0043] (2) Add the modified organic aluminum salt into the reaction vessel, turn on the stirring device, and add 0.2 g of hydroxyethyl cellulose and 5 g of calcium acetate in turn to ensure that each material is stirred evenly before adding the next material. The reaction time is controlled to be 2 hours, and the temperature of the reactant is ensured to be 15-20° C. through temperature control measures throughout the whole process, and the modified...

Embodiment 3

[0045] The only difference from Example 1 is: 35 g of triethyl aluminum and 12 g of dimethyl aluminum hypophosphite.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com