Light guide system, direct type backlight mould and liquid crystal display

A technology for backlight modules and light introduction, which is applied in light guides, optical fiber light guides, light guides of lighting systems, etc., can solve problems such as large brightness differences and affect the optical quality of backlight modules, and achieve energy consumption reduction, optical quality improvement, and luminous The effect of widening the angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

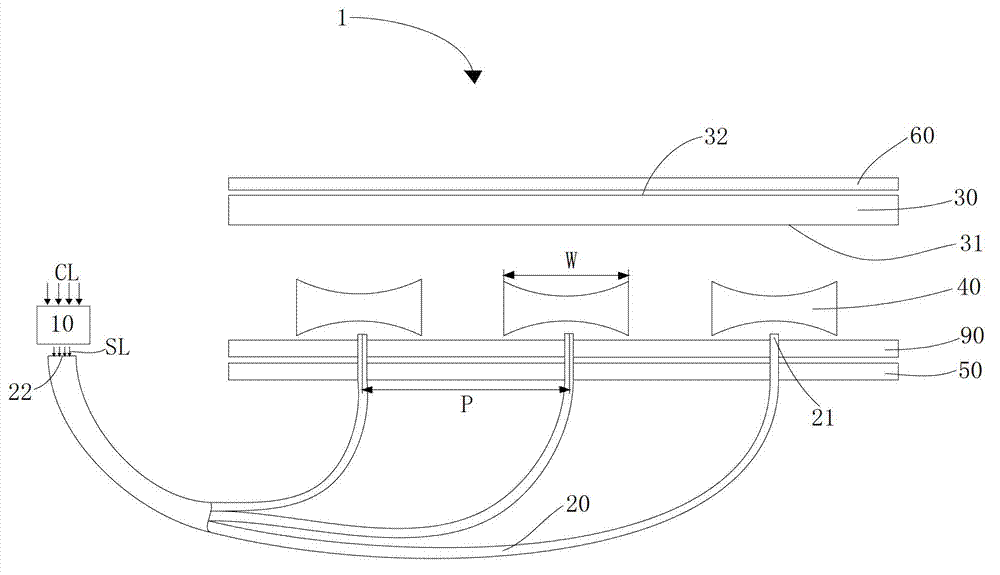

[0022] refer to figure 1 , The direct type backlight module 1 includes an ambient light collection system 10 , several optical fibers 20 , several biconcave lenses 40 , a backplane 50 , a diffusion plate 30 , an optical film 60 and a reflection plate 90 . Wherein, the diffusion plate 30 includes a light incident surface 31, a light exit surface 32 opposite to the light incident surface 31, a reflector 90 arranged under the light incident surface 31, a back plate 50 arranged under the reflector 90, and an optical film 60 It is arranged on the light-emitting surface 32 .

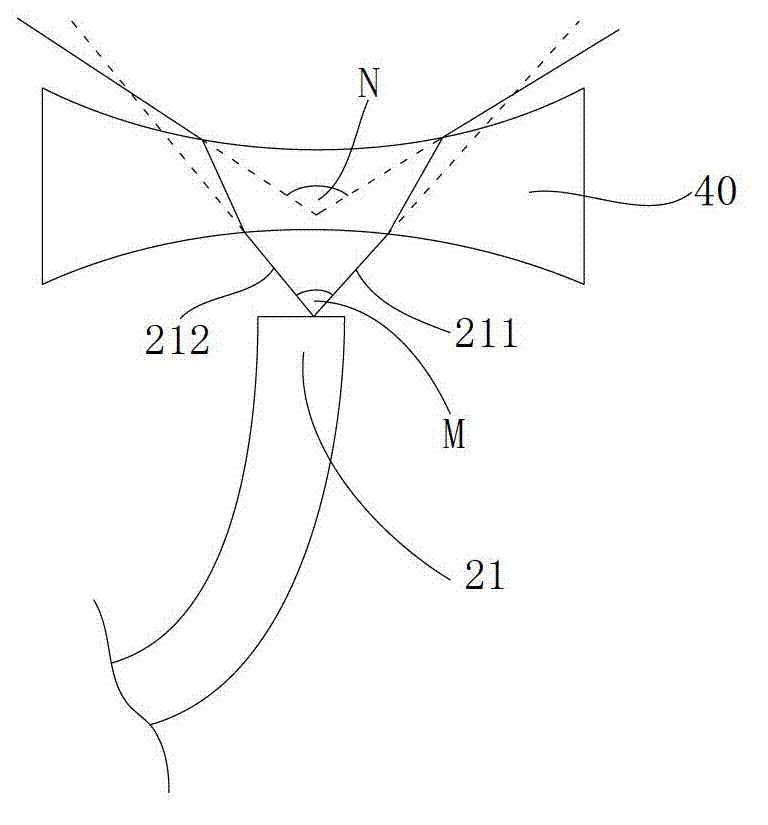

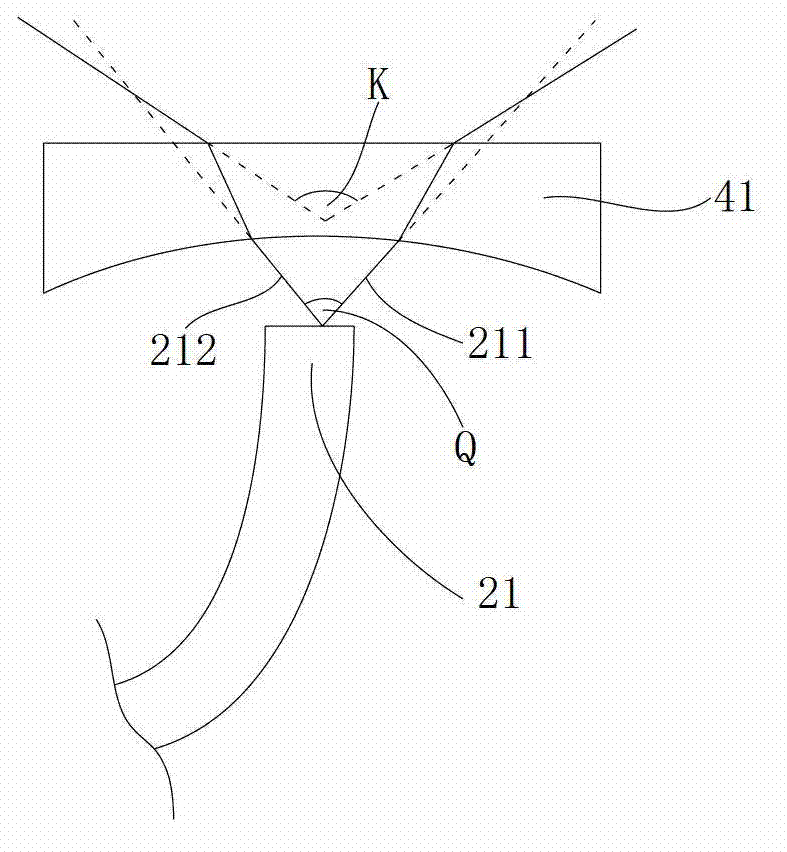

[0023] In this embodiment, the ambient light collection system 10, several optical fibers 20 and several double-concave lenses 40 form a light introduction system, wherein each optical fiber 20 has a light-emitting end 21 and a light-entry end 22, and the entrance of each optical fiber The light ends 22 are converged into a bundle and then adjacent to the ambient light collection system 10 , the light output ...

Embodiment 2

[0034] In the description of Embodiment 2, the same content as in Embodiment 1 will not be repeated here, and only the content that is different from Embodiment 1 will be described below.

[0035] Light-emitting diodes (LEDs), as an original backlight light source commonly used in backlight modules, use electric energy as the power to emit light. Of course, the original backlight light source can also be fluorescent lamps, CCFLs and other illuminants powered by electric energy.

[0036] refer to Figure 5, the direct type backlight module 1 may also include several LEDs 70 , the LEDs 70 and the light outlets 21 are alternately arranged on the reflector 90 , that is, the LEDs 70 and the light outlets 21 are alternately arranged under the light incident surface 31 . A biconcave lens 40 is provided between the light exit end 21 and the light incident side 31 , of course, as mentioned above, the biconcave lens can also be replaced by a plano-concave lens. Through this structure,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com