Printing defect detection method based on flexible template registration

A technology for printing defects and detection methods, applied in the direction of optical testing defects/defects, etc., can solve the problems of weak tolerance of image geometric inconsistency, waste of products and human resources, and low production efficiency, so as to reduce the risk of waste leakage and improve detection. Accuracy, the effect of maintaining tolerance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

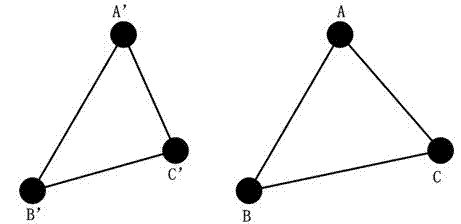

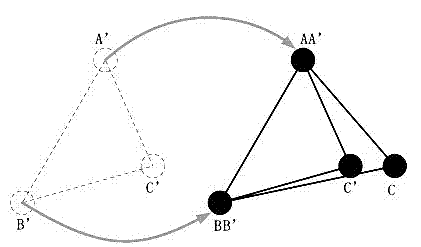

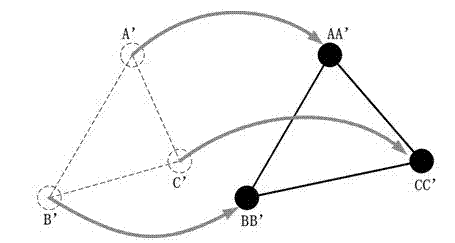

[0042] The present invention uses rigid registration for initial positioning, and for any pixel in the image to be registered after the rigid initial registration is completed, a corresponding pixel can be found near the same coordinates of the target image (standard image, template). Composition of pixel pairs, the similarity measure between them (the similarity measure of two objects refers to the degree of their proximity to each other in Euclidean space, the commonly used similarity measure calculation methods are Euclidean distance, correlation coefficient or information entropy, etc. ) is higher. The coordinate difference between each pixel pair is recorded. The overall similarity measure and coordinate difference degree of all pixel pairs are used as the optimization objective function:

[0043] C = -C similarity +C deformation ,

[0044] where C similarity is a similar energy term, C deformation is the deformation energy term;

[0045] The similarity measure u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com