Variable scale edge passivation waverider configuration and passivation method

A waveriding configuration and scale-changing technology, applied in the field of hypersonic vehicles, can solve problems such as pressure difference reduction, lift-to-drag ratio reduction, and waveriding configuration lift performance degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

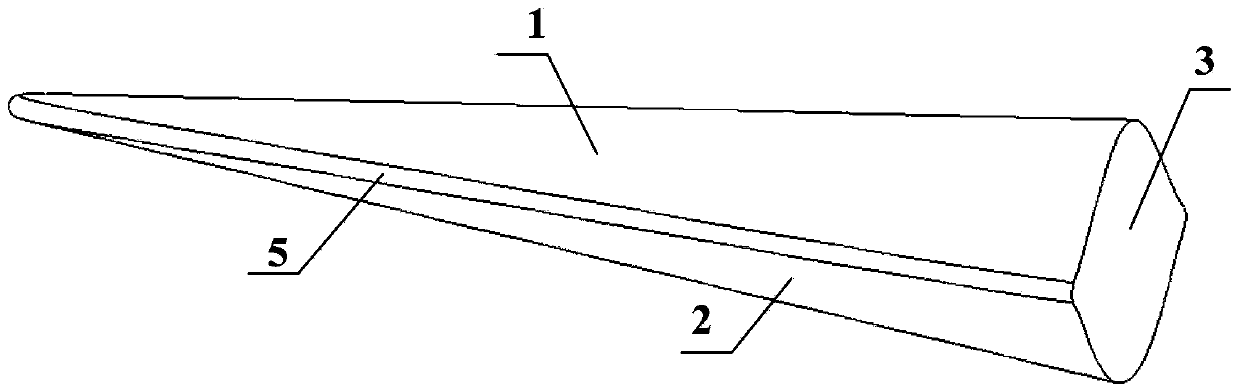

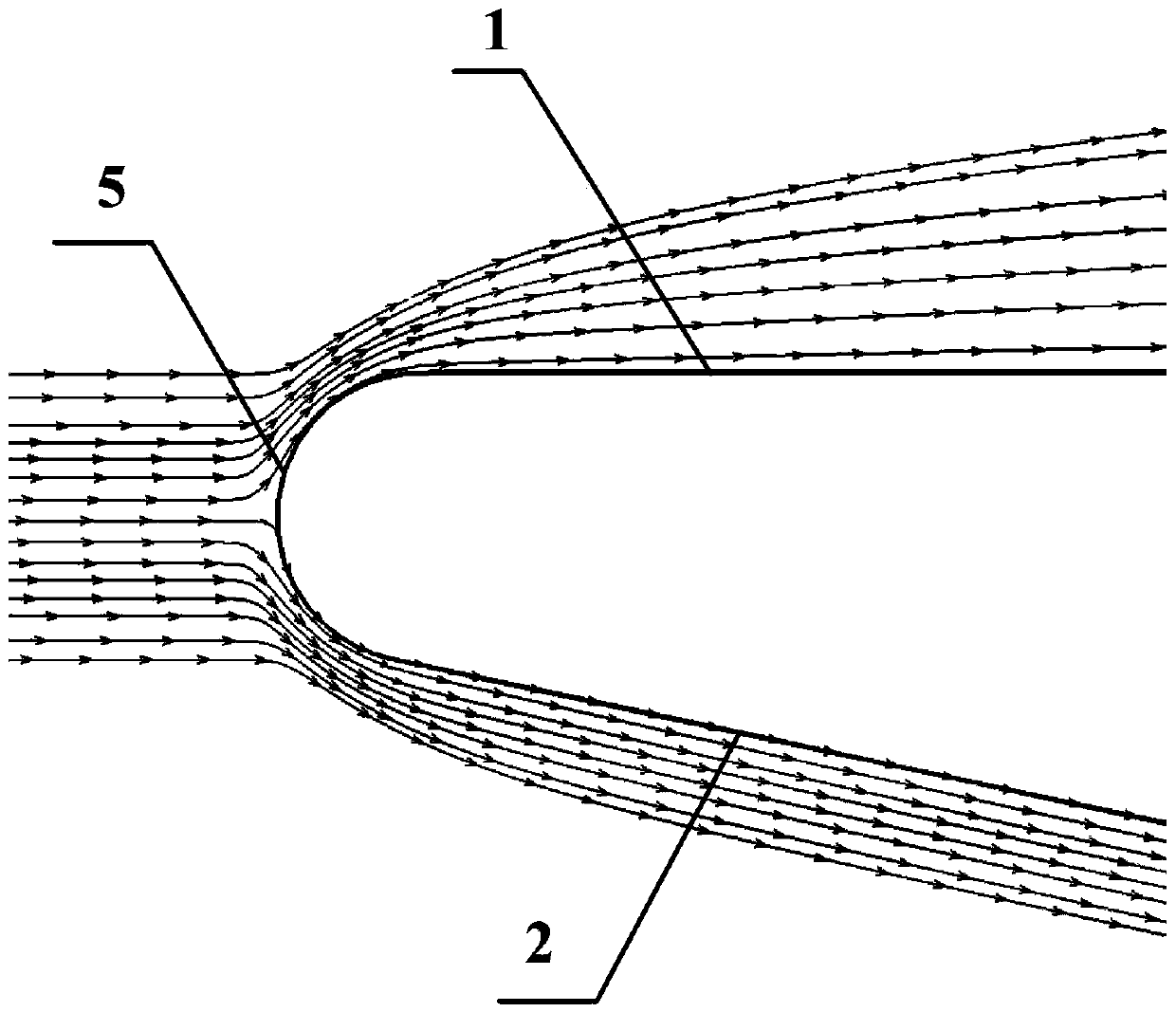

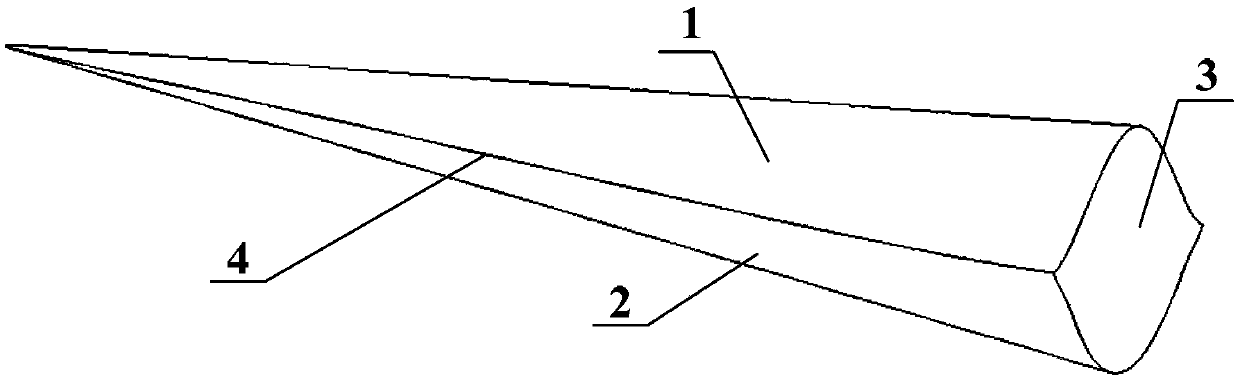

[0038] a kind of like Figure 6 ~ Figure 10 The shown variable-scale edge passivation waverider configuration of the present invention is based on Figure 3 ~ Figure 5 The sharp-edge waverider configuration shown is a passivated precursor, which includes an upper surface 1 and a lower surface 2. The upper surface 1 and lower surface 2 of the sharp-edge waverider configuration intersect to form a sharp-edge waverider type edge line 4; the edge line 4 of the sharp edge waverider configuration includes a stagnation point 7 at the middle position and tail end points 8 at both ends, and the stagnation point 7 is the frontmost point of the tip edge waverider configuration. is the first position to contact the incoming flow; the tail end point 8 is the intersection point of the edge line 4 of the tip-edge waverider configuration and the bottom surface 3 of the sharp-edge waverider configuration; the edge line 4 of the sharp-edge waverider configuration is 7 is divided into a left edge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com