Device for dip coating and baking motor stator

A motor stator and paint impregnation technology, which is applied in electromechanical devices, manufacturing motor generators, electrical components, etc., can solve problems such as uneven paint distribution and paint sagging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the objectives, technical solutions and advantages of the present invention clearer, the embodiments of the present invention will be further described in detail below with reference to the accompanying drawings.

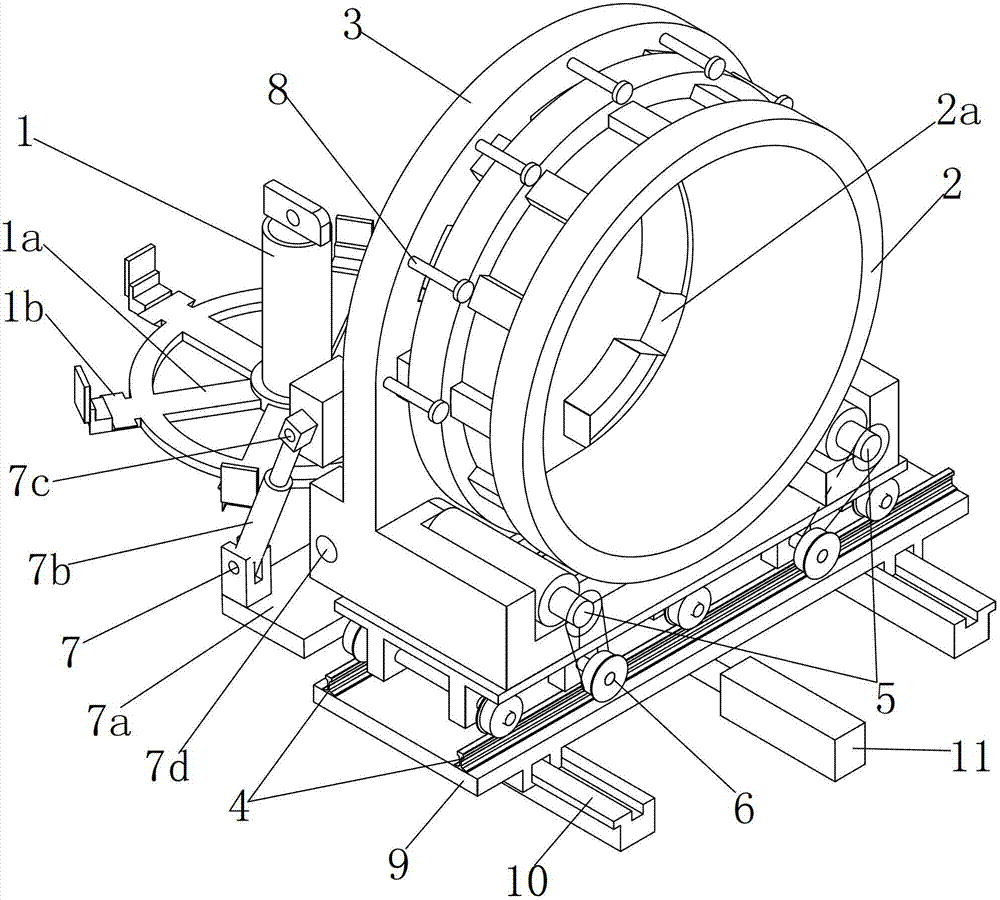

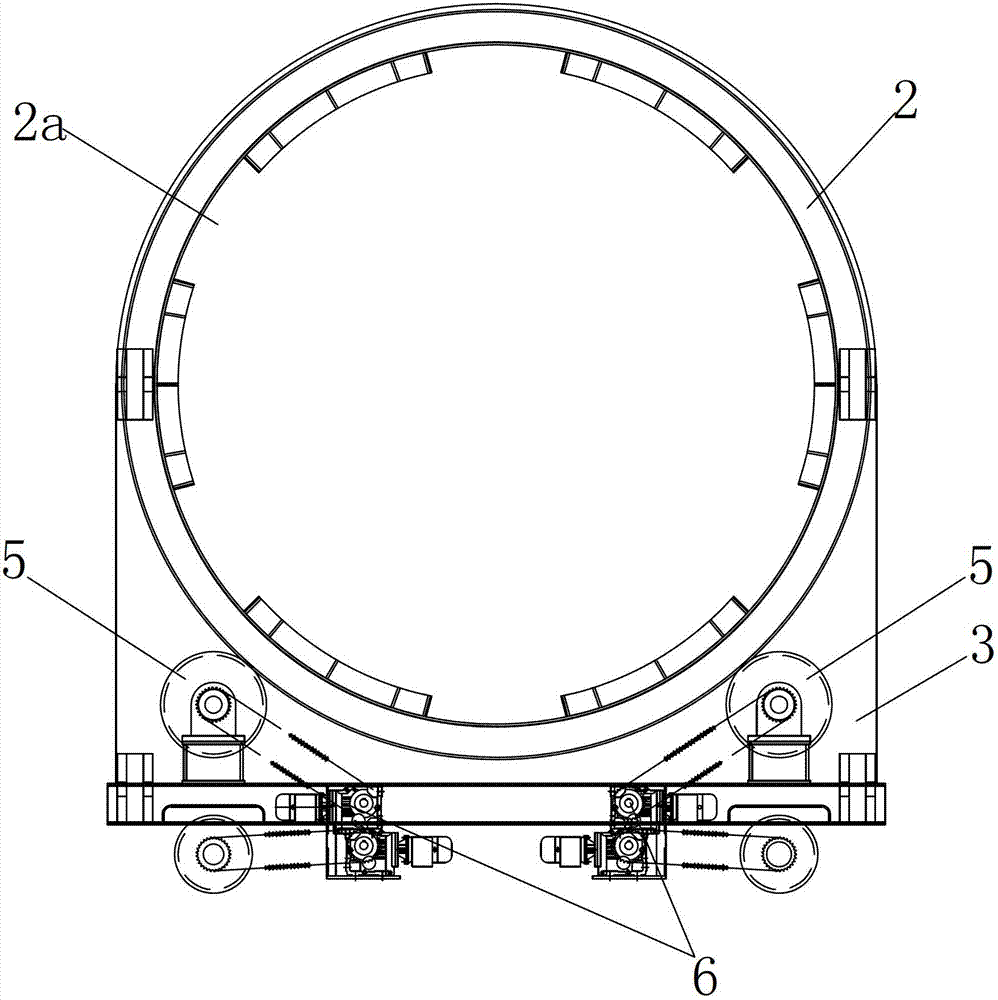

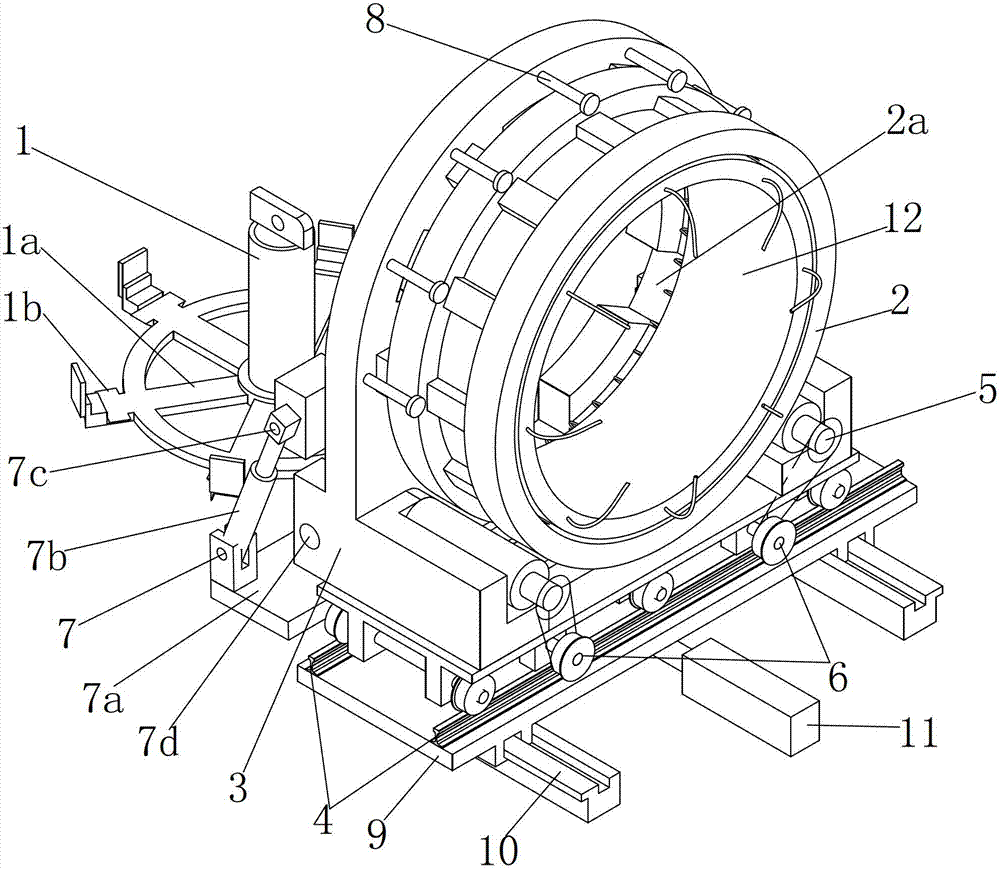

[0025] like figure 1 As shown, the present invention provides a device for dipping and baking the motor stator 12, including a paint dipping hanger 1, a revolving cage 2 and a revolving cage transport platform 3 and a sliding rail 4 that cooperate with each other. The cage 2 is supported and installed on the revolving cage transport platform 3 through the rotating wheel 5, and the rotary cage transport platform 3 is provided with a motor 6 that is drivingly connected to the rotating wheel 5; one side of the sliding rail 4 An overturning mechanism 7 is provided for overturning the revolving cage transport platform 3 . The revolving cage 2 can be rotated and baked by the added rotating wheel 5 and the motor 6; at the same time, the added turni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com