Self-aligned coverage of opaque conductive areas

A transparent conductive, self-aligned process technology, applied in circuits, electrical components, semiconductor devices, etc., can solve the problems of waste of functional areas of light and difficulty in mask coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

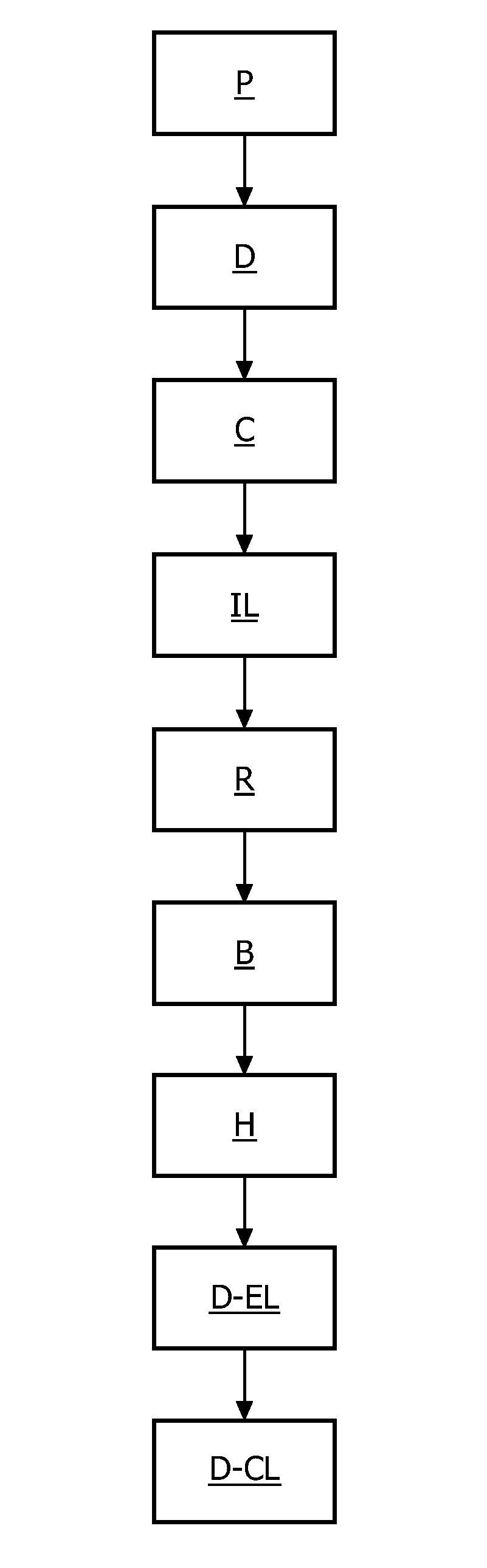

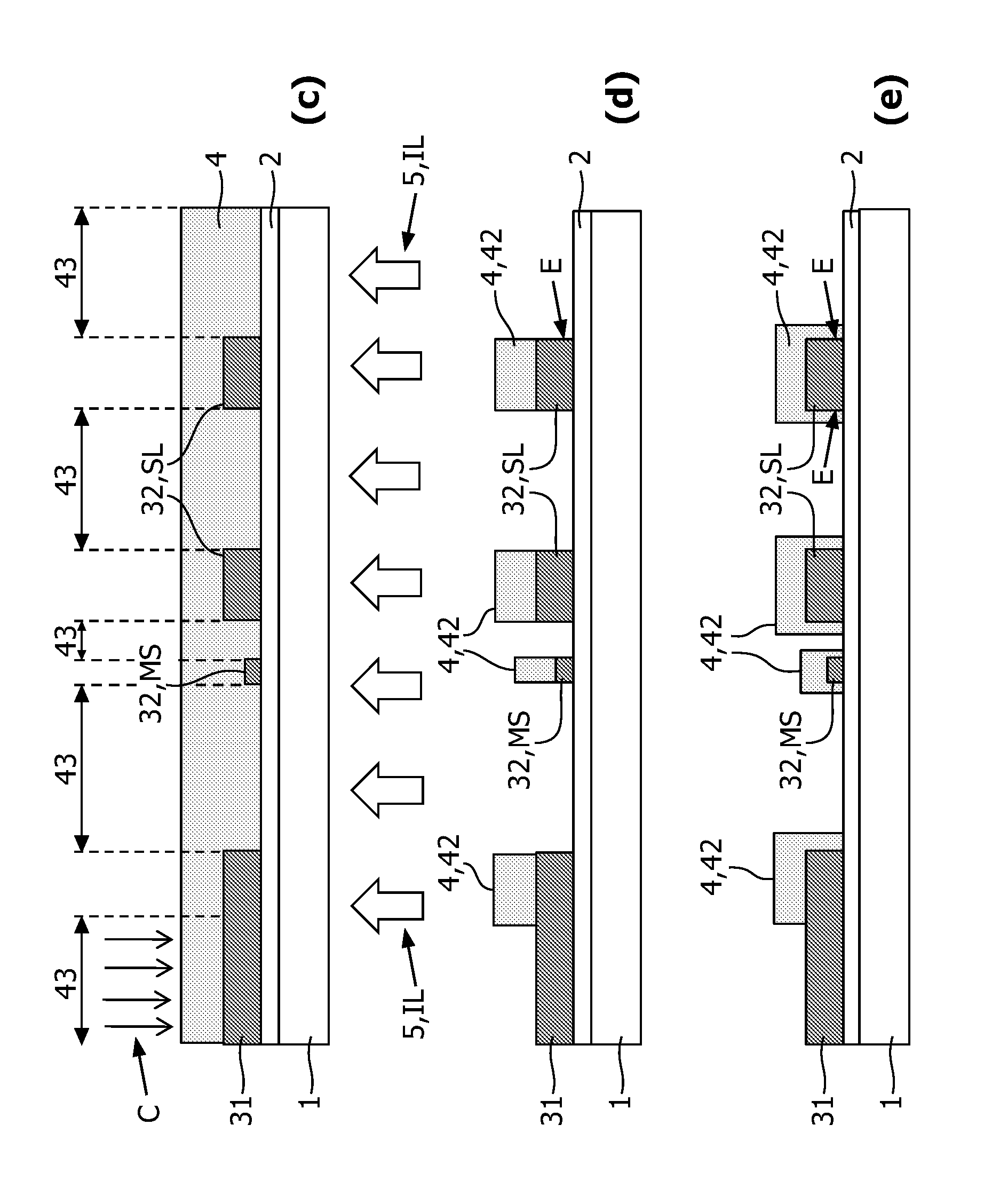

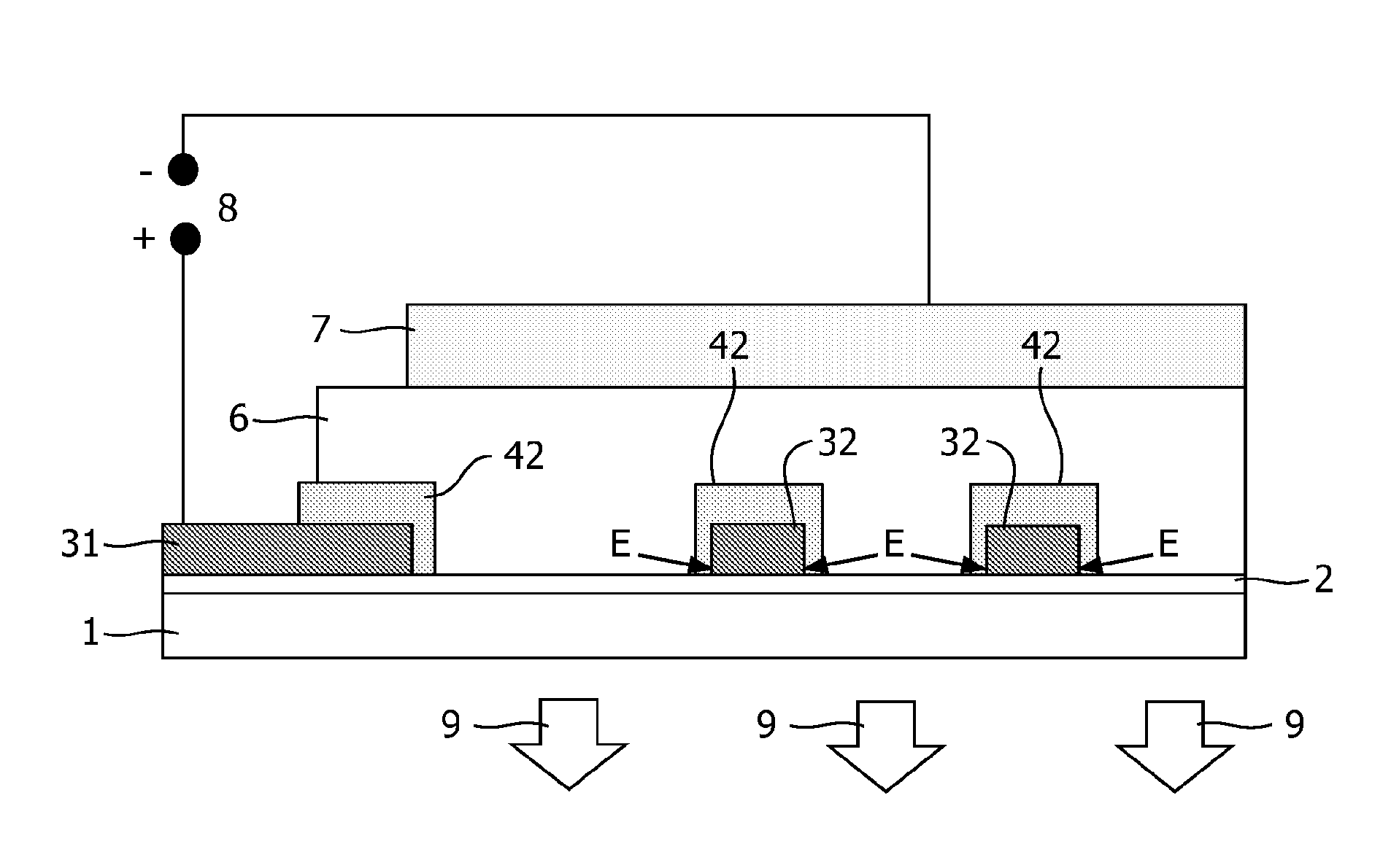

[0032] figure 1 An embodiment of a method according to the invention for covering an opaque conductive area in a self-aligned process is shown, the method comprising process steps (a)-(e), wherein figure 1 (a) shows that the conductive component comprises a substrate 1 , a transparent conductive layer 2 deposited on a transparent substrate 2 with first and second opaque conductive regions 31 , 32 . In this embodiment, the first and second opaque conductive regions are arranged as metal regions, for example as aluminum regions. The first area 31 is arranged as a contact pad for contacting the electrically conductive transparent layer 2 as one of the electrodes of a later completed organic electroluminescent device connected to an external power source to drive the organic electroluminescent device. A typical thickness of such contact pads is 500 nm, the printed silver may have a thickness of 1 μm. The first metal region 31 as this opaque conductive region may be evaporated, p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com