Method and device for preparing rare earth-doped nano-titanium dioxide photocatalyst by supercritical carbon dioxide method

A nano-titanium dioxide and carbon dioxide technology, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problem that the photocatalytic performance cannot be better breakthrough, etc. To achieve the desired effect of photocatalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

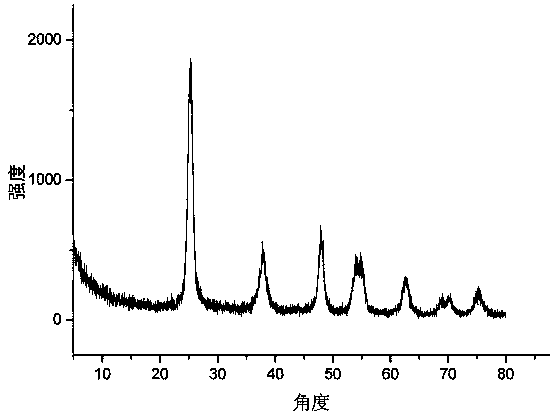

[0022] Example 1, see figure 1

[0023] (1) Take 17ml of tetrabutyl titanate, La(NO 3 ) 3 ·nHO 2 Weigh 0.6498g, dissolve in 150ml of absolute ethanol, stir well until the nitrate hydrate is completely dissolved to obtain a uniform solution, and add it to the reaction kettle A41, stirring at an appropriate speed; heat A41 to 120°C; High-purity CO 2 Pump into A41, the pressure rises to 430bar, close k3;

[0024] (2) Add 6ml of deionized water into the preheating container A31 and raise the temperature to 120°C; 2 Pump into the reactor A31, raise the pressure to 450bar;

[0025] (3) Open k4, the deionized water in A31 will be supercritical CO 2 The fluid is carried into the A41, and the deionized water and the liquid medicine are fully mixed and reacted under the action of stirring. Continue to pump CO into A31 2 To achieve a holding pressure value of 450bar, constant pressure and temperature for 24 hours;

[0026](4) After the reaction is over, collect the material fro...

Embodiment 2

[0027] Embodiment 2: see figure 1 ,

[0028] (1) Take 8ml of tetrabutyl titanate, Y(NO 3 ) 3 ·6HO 2 Weigh 0.0479g, dissolve it in 70ml of absolute ethanol, stir well until the nitrate hydrate is completely dissolved to obtain a uniform solution, and add it to the reaction kettle A41, stirring at an appropriate speed; heat A41 to 140°C; High-purity CO 2 Pump into A41, the pressure rises to 320bar, close k3;

[0029] (2) Add 3ml of deionized water into the preheating container A31 and raise the temperature to 140°C; 2 Pump into the reactor A31, raise the pressure to 350bar;

[0030] (3) Open k4, the deionized water in A31 will be supercritical CO 2 The fluid is carried into the A41, and the deionized water and the liquid medicine are fully mixed and reacted under the action of stirring. Continue to pump CO into A31 2 To achieve a holding pressure value of 350bar, constant pressure and temperature for 16 hours;

[0031] (4) After the reaction is over, collect the materi...

Embodiment 3

[0032] Example 3, see figure 1

[0033] (1) Take tetraisopropyl titanate 15ml, Gd(NO 3 ) 3 ·6HO 2 Weigh 0.0925g, dissolve in 140ml of absolute ethanol together, stir well until the nitrate hydrate is completely dissolved to obtain a uniform solution, and add it to the reaction kettle A41, stirring at an appropriate speed; heat A41 to 140°C; High-purity CO 2 Pump into A41, the pressure rises to 220bar, close k3;

[0034] (2) Add 6ml of deionized water into the preheating container A31 and heat up to 140°C; 2 Pump into the reactor A31, raise the pressure to 250bar;

[0035] (3) Open k4, the deionized water in A31 will be supercritical CO 2 The fluid is carried into the A41, and the deionized water and the liquid medicine are fully mixed and reacted under the action of stirring. Continue to pump CO into A31 2 To achieve a holding pressure value of 250bar, constant pressure and temperature for 8 hours;

[0036] (4) After the reaction is over, collect the material from t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com