Cellulose degradation complex microbial inoculant as well as preparation method and application thereof

A technology of cellulose degradation and compound bacterial agent, which is applied in the direction of biochemical equipment and methods, methods based on microorganisms, bacteria, etc., can solve the problems of limiting bacterial species, and achieve the promotion of degradation, plant growth, safety and harmlessness The effect of enhancing the degree of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] Embodiment 1: the construction of composite bacterial agent

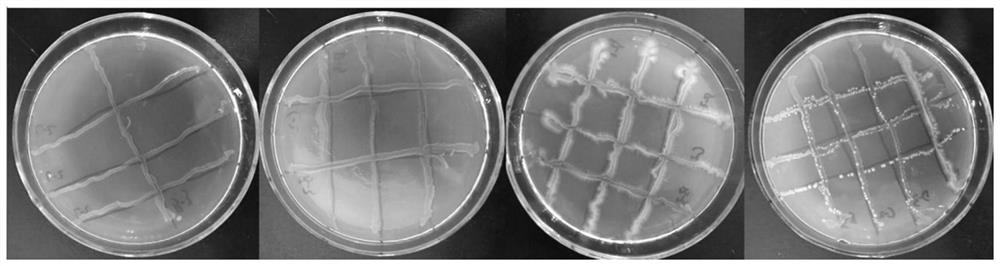

[0055] Strain antagonism test: five strains of Bacillus mycoides, Serratia marcescens, Corynebacterium glutamicum, and Trichoderma reesei were subcultured and stabilized. and Aspergillus fumigatus (Aspergillus fumigatus) in the CMC-Na solid medium for two-two cross-streaking, when the strains grow into strips, observe whether there is a zone of inhibition at the intersection of different strains, to detect whether the strains can be used in the construction of complex bacterial strains. see results figure 1 (From left to right in the figure are the cross-hatched results of two strains, three strains, four strains and five strains of bacteria). The intersection of each strain grows well, without antagonistic effect, and can be combined and compounded.

[0056] Determination of enzyme activity of complex bacterial strains: random combination of different bacterial strains (combination I-combination IV) with ...

Embodiment 2

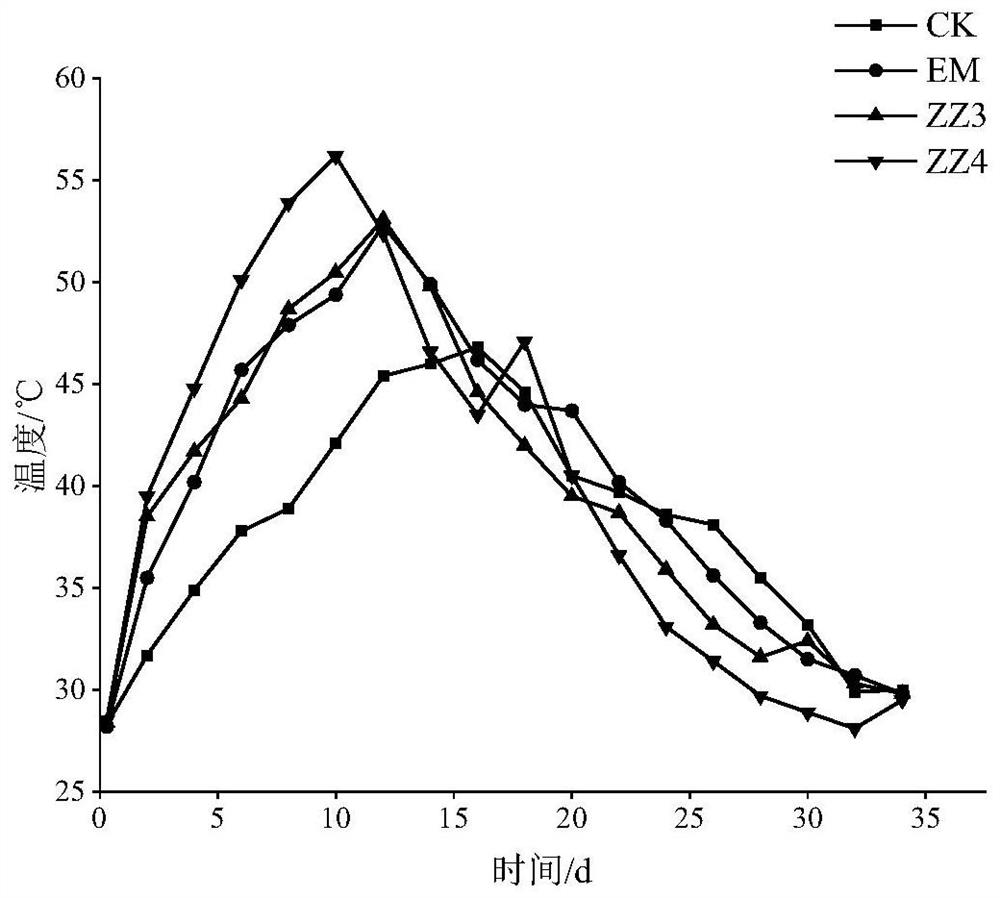

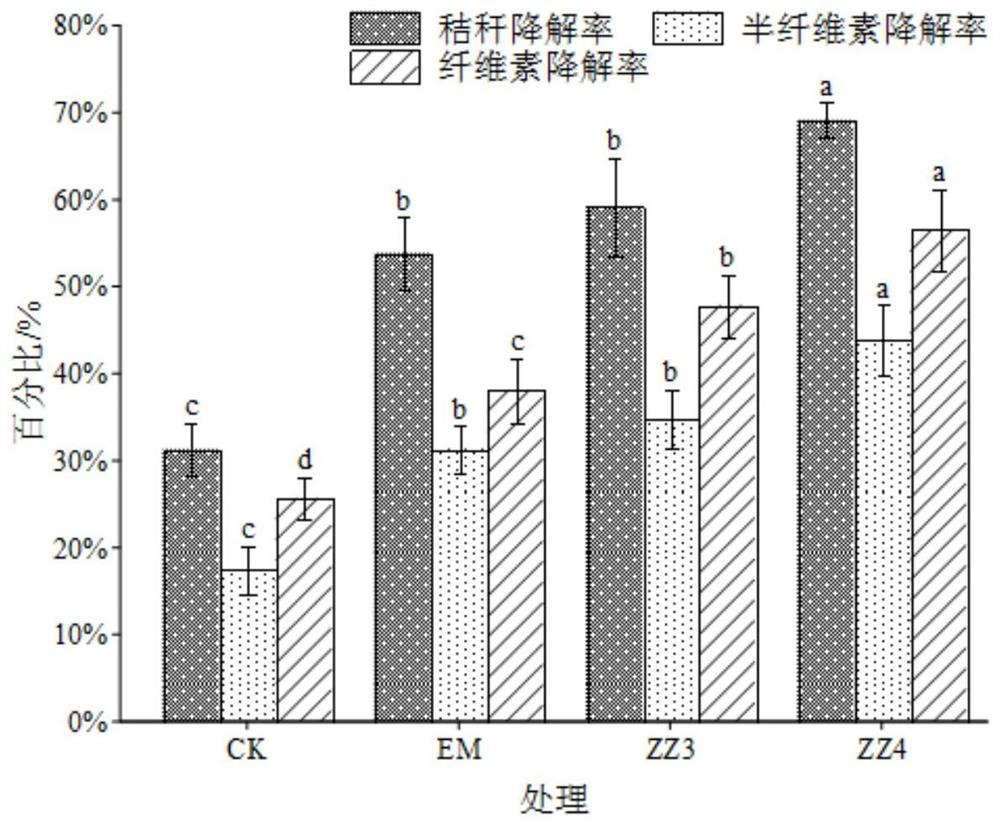

[0064] Example 2: Detection of straw degradation effect of compound bacterial agent

[0065] Soak the straw with 1% NaOH solution for 30 minutes to remove the surface wax and increase the contact degree between the cellulose-degrading bacteria and the cellulose component of the straw. Cut the soaked straw into small pieces of about 5 cm, and soak in deionized water for 24 hours to promote the dissolution of available carbon and nitrogen and adjust the moisture content appropriately. The treated straw was oven-dried at 50° C. and stacked in a fermenter, and urea was added to adjust the C / N to 30 to obtain the pretreated straw raw material.

[0066] The experiment consisted of 4 treatments, namely:

[0067]CK treatment: inoculate the liquid enzyme-producing medium equal to the volume of the bacterial agent on the pretreated straw raw material, mix evenly and then ferment continuously.

[0068] EM treatment: Inoculate the EM bacterial agent (purchased from Tai'an Putian Reagent...

Embodiment 3

[0077] Embodiment 3: Composite bacterial agent Ⅳ carrier screening experiment

[0078] In the present invention, 7 kinds of carriers are selected, which are respectively: inorganic materials (activated carbon, zeolite powder, vermiculite, diatomaceous earth) and organic materials (wheat bran, straw powder, peat soil). All kinds of materials were ground and passed through a 30-mesh sieve, sterilized at 121°C for 30 min, and dried for later use. Before inoculating the carrier, the initial number of viable bacteria in each treatment solution was determined. The specific operation is: under aseptic conditions, mix different carriers and compound bacterial agent IV according to the ratio of 10 g carrier to 40 ml bacterial solution, and then culture at 30°C. The culture carrier was sampled at 5h, 10h, 24h, 2d, 4d, 8d, 14d, and 22d respectively, and 0.2g carrier was taken each time, and distilled water was added to make the volume to 5ml, shaken at 120r / min for 15min, and then centr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com