Three-jaw centrifugal force self-centering chuck

A self-centering chuck and centrifugal force technology, applied in the direction of the chuck, etc., can solve the problems of complex operation and maintenance, low production efficiency, long manufacturing cycle, etc., and achieve the effects of convenient use, improved production efficiency, and improved processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

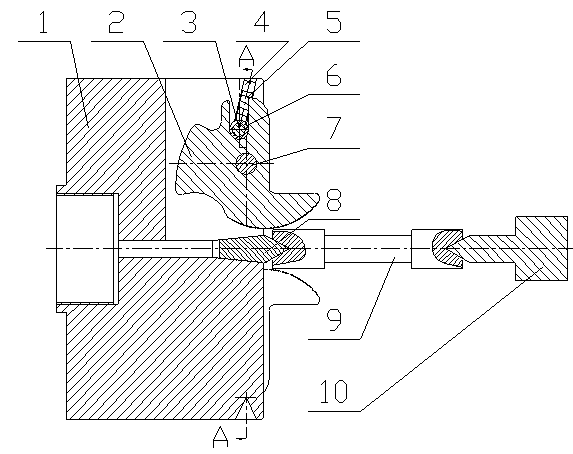

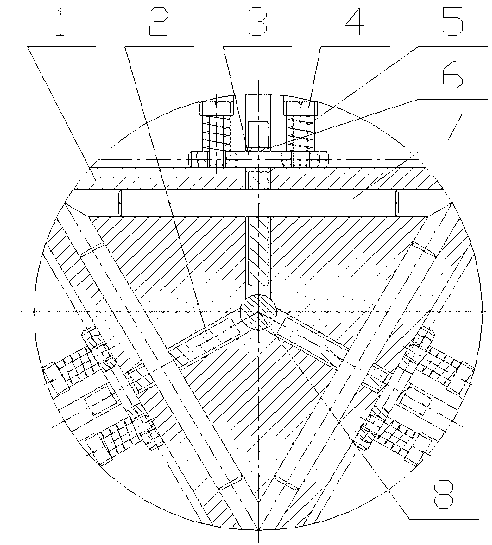

[0016] like figure 1 and figure 2 As shown, a three-jaw self-centering chuck includes a chuck body 1, jaws 2, a centrifugal shaft 3, a plug shaft 4, a centrifugal roller sleeve 6 and a fixed shaft 7. There are three evenly distributed straight grooves on the end surface of the chuck body 1, and the jaws 2 are placed in the straight grooves. There are three evenly distributed chute grooves on the circumferential direction. Parallel and symmetrical internal threaded holes, the diameter of the internal threaded hole is larger than the width of the chute; there are three evenly distributed fixed shaft holes and a center hole inside the chuck body. The plug shaft 4 is screwed in the internally threaded hole of the chuck body 1 by external threads, and the plug shaft 4 is covered with a compression spring 5, which is installed in the internally threaded ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com