Method and device for preparing low-moisture-content and low-acidity bio-oil through fast pyrolysis

A technology with low water content and bio-oil, which is applied in the preparation of biofuels, liquid hydrocarbon mixtures, and the petroleum industry. It can solve the problems of high water and acid content and difficult separation, and achieve the reduction of water content and acidity, and good dehydration and acid removal. , Improve the effect of calorific value and chemical application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

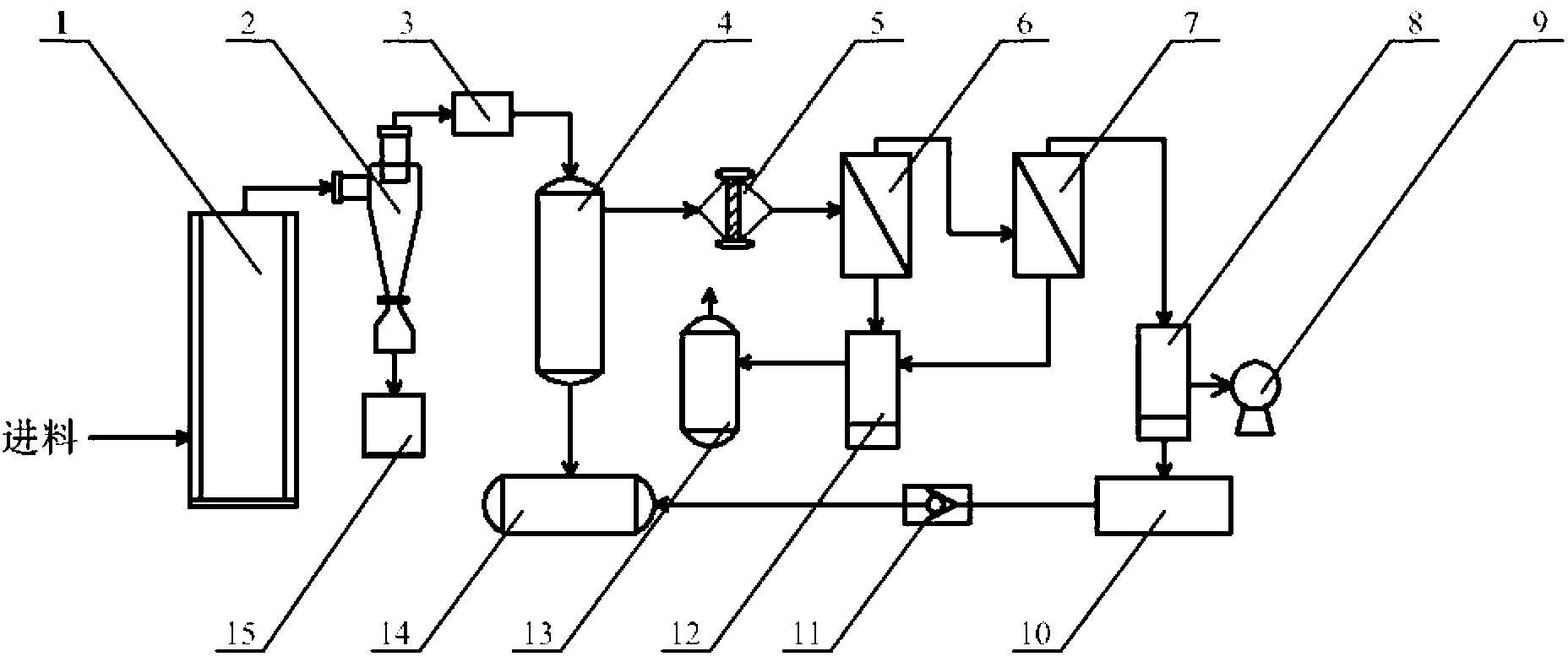

Embodiment 1

[0073] The biomass raw material is larch species, with a moisture content of 8.7% and a particle size of 0.9-1.2mm. First turn off the vacuum pump 9, heat the pyrolysis reactor 1 to 450°C, turn on the vacuum pump 9, turn on the first-stage condenser 4, the second-stage condenser 8 and the third-stage condenser 12, and continuously add the above-mentioned granular larch material to the heat The reactor 1 is decomposed, and the liquid in the temporary storage tank 10 enters the oil storage tank 14 through the one-way valve 11, and after feeding for 1 hour, the reaction ends. It is measured that the moisture content of the liquid in the vinegar liquid storage tank 13 is 60%, and the pH=3.5; the pH value of the oil storage tank 14 is 6.2, and the moisture content is 7.8%.

Embodiment 2

[0075] The biomass raw material is corn stalks with a moisture content of 7.9% and a particle size of 0.6-0.9mm. First turn off the vacuum pump 9, heat the pyrolysis reactor 1 to 550°C, turn on the vacuum pump 9, turn on the first-stage condenser 4, the second-stage condenser 8 and the third-stage condenser 12, and continuously add the above-mentioned granular larch material to the heat The reactor 1 is decomposed, and the liquid in the temporary storage tank 10 enters the oil storage tank 14 through the one-way valve 11, and after feeding for 1 hour, the reaction ends. It is measured that the moisture content of the liquid in the vinegar storage tank 13 is 65%, and the pH value is 3.3; the pH value in the oil storage tank 14 is 6.5, and the moisture content is 8.2%.

[0076] In one embodiment of the device of the present invention, the model of the pyrolysis reactor used is BJFU-FPOA-220, designed by Beijing Forestry University and produced by Beijing Kunlun Yongtai Technolog...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap