Efficient energy-saving environment-friendly mechanical sealing device

A mechanical sealing device, high-efficiency and energy-saving technology, applied in the direction of sealing/seal, wellbore/well parts, earthwork drilling and mining, etc., can solve the problems of cumbersome seal replacement, long replacement time, troublesome replacement, etc., to achieve installation and replacement The sealing strip is simple and easy to operate, compact in structure, and has the effect of increasing the safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

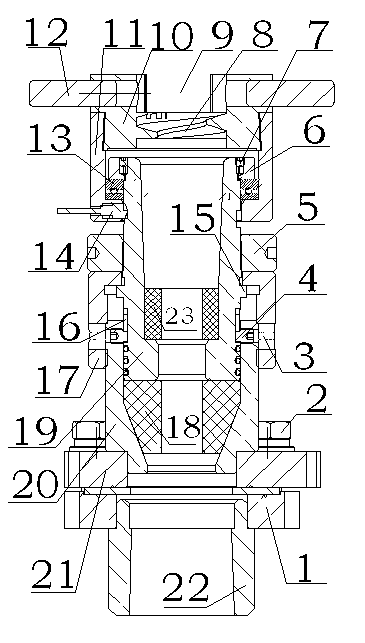

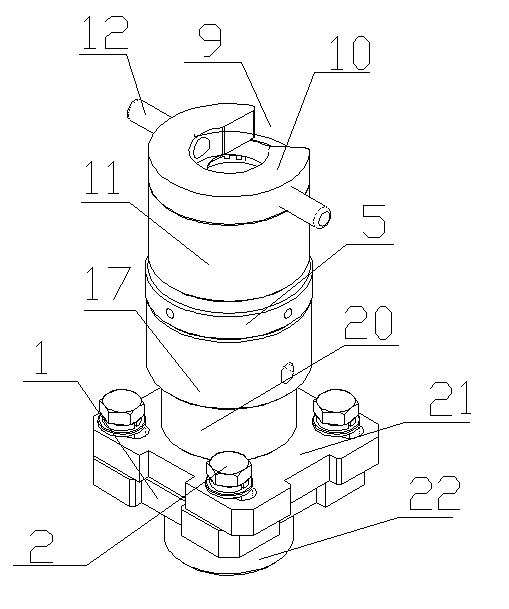

[0015] The present invention has gap 9 on the side wall of screw nut 10, and the side wall that runs through the center hole of screw nut 10 is a spiral channel 8. By this structure, a groove with a gap is formed on the screw nut 10, and the gap and the spiral The threaded inlet end of the channel just corresponds, which is convenient for inserting the sealing strip; the screw nut 10 is threadedly connected with the bearing seat 11, the upper end of the secondary sealing body 19 is inserted in the bearing seat 11, and the side wall of the upper end of the secondary sealing body 19 is installed through the stabilizing nail 7 There is a pressure cap 6, and the stabilizing nail can firmly fix the pressure cap on the secondary sealing body. A thrust ball bearing 13 is installed between the pressure cap 6 and the bottom end of the bearing seat 11, and the inner tile of the thrust ball bearing is tightly attached to the On the pressure cap, the outer bush is tightly attached to the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com