Flashlight

A flashlight and conductive sleeve technology, applied in the field of flashlights, can solve the problems of expensive metal shells and poor conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Now carry out further explanation in conjunction with accompanying drawing.

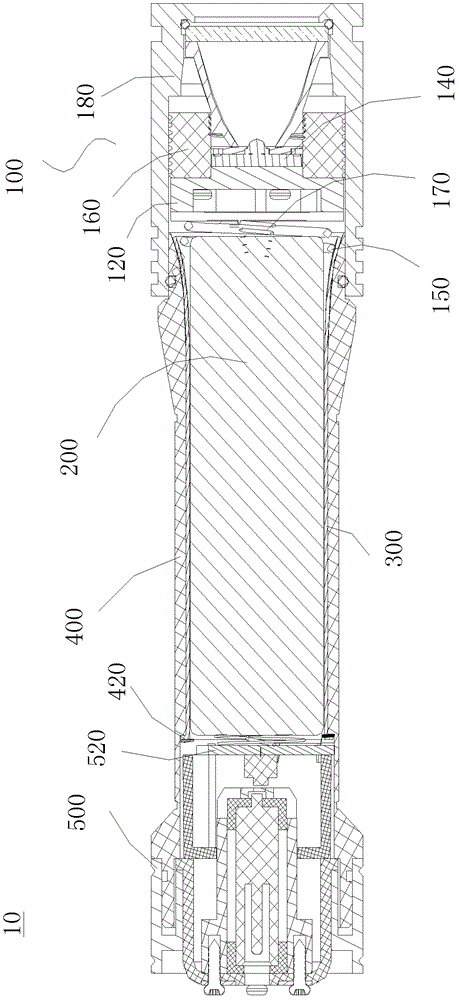

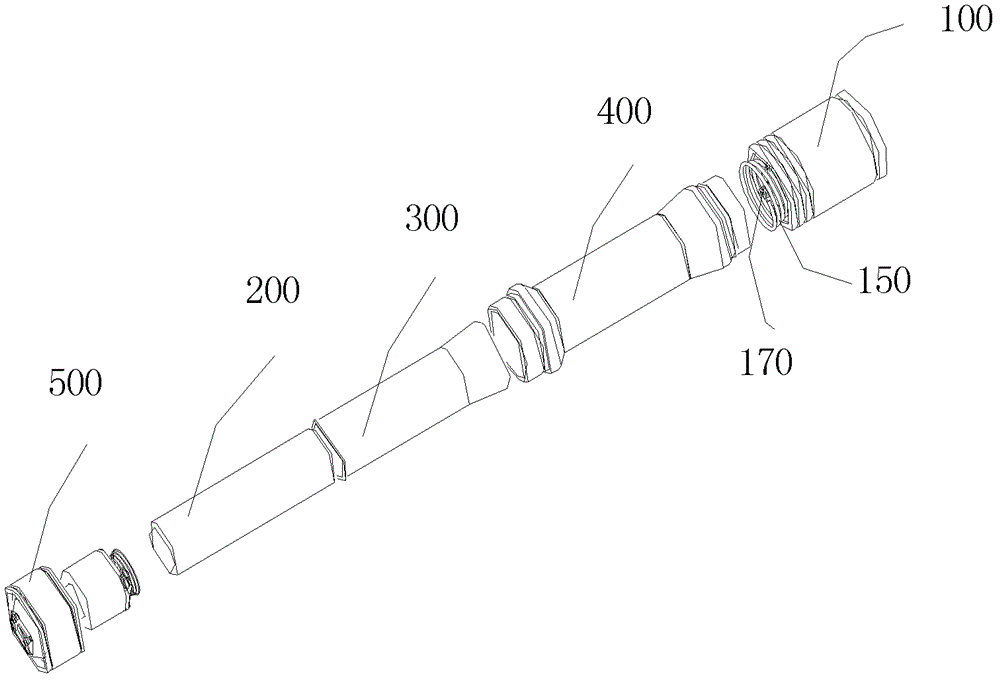

[0019] Such as figure 1 with figure 2 As shown, the flashlight 10 includes a light source part 100 , a conductive sleeve 300 , a barrel body 400 and a tail cap 500 . The light source part 100 and the tail cap 500 are respectively located at two ends of the barrel body 400 , and the conductive sleeve 300 is disposed adjacent to the inner wall of the barrel body 400 .

[0020] The light source part 100 includes a light source circuit board 120 and a light source 140 disposed thereon. The light source 140 is closely surrounded by a cooling frame 160 , the cooling frame 160 is screwed with the lamp head barrel 180 , and the light source circuit board 120 and the light source 140 are fixed in the lamp head barrel 180 , and the lamp head barrel 180 and the barrel body 400 are connected by threads.

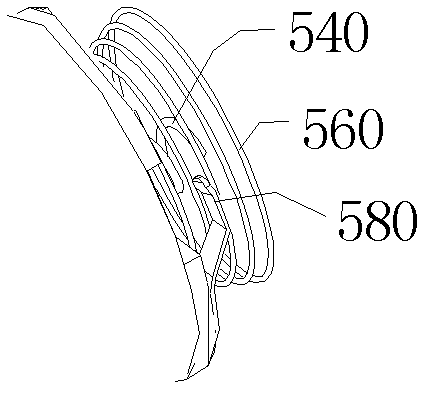

[0021] One side of the light source circuit board 120 is provided with a light source 140, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com