Detection mechanism of spigot

A detection mechanism and notch technology, which is applied in the direction of measuring devices, mechanical devices, mechanical measuring devices, etc., can solve the problems of too many positioning detection devices, reduced layout space of inspection tools, and many notch detection points, etc., to achieve detection High efficiency, reduce production cost, solve cumbersome effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention is described in detail with reference to the accompanying drawings, but the protection scope of the present invention is not limited to the following examples.

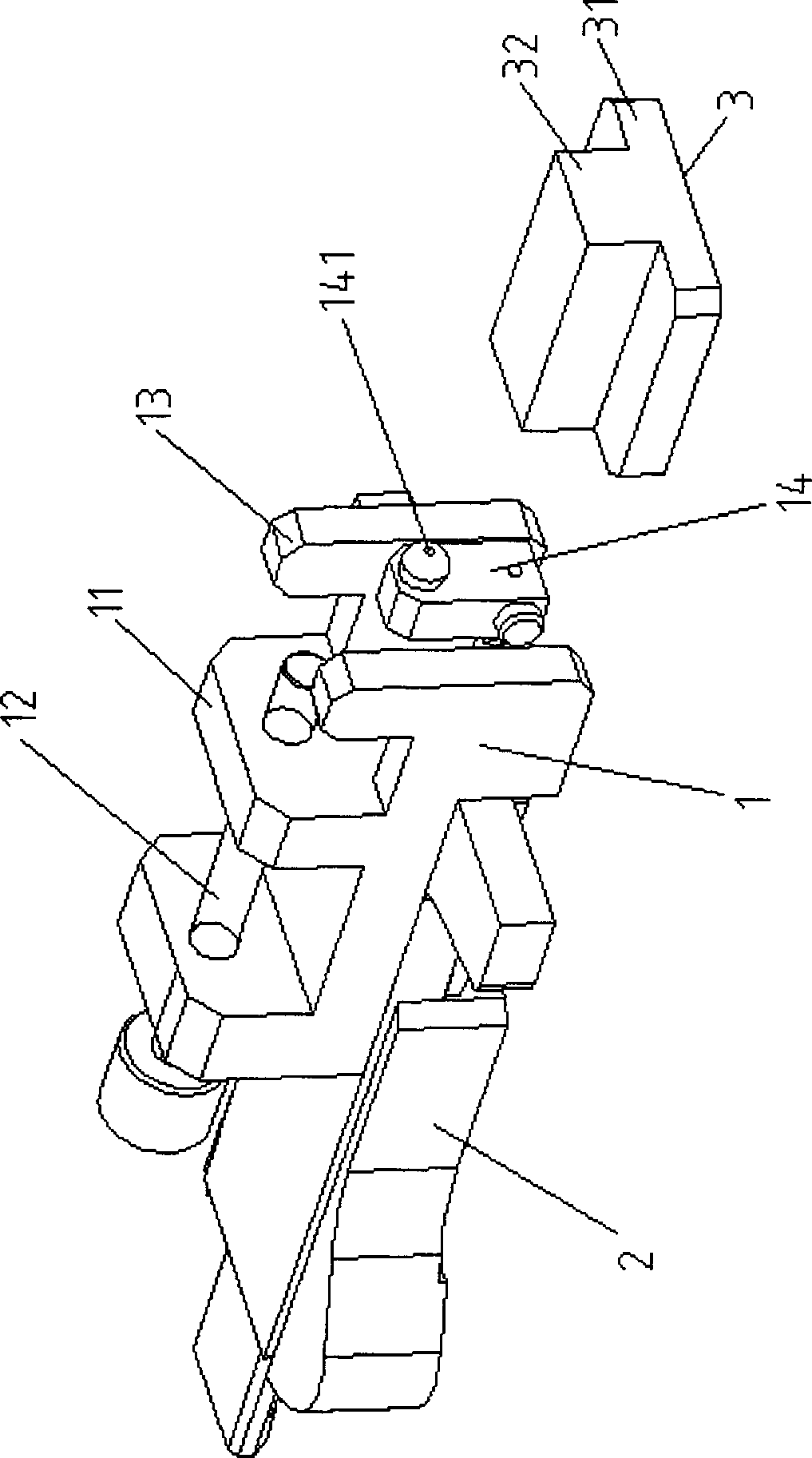

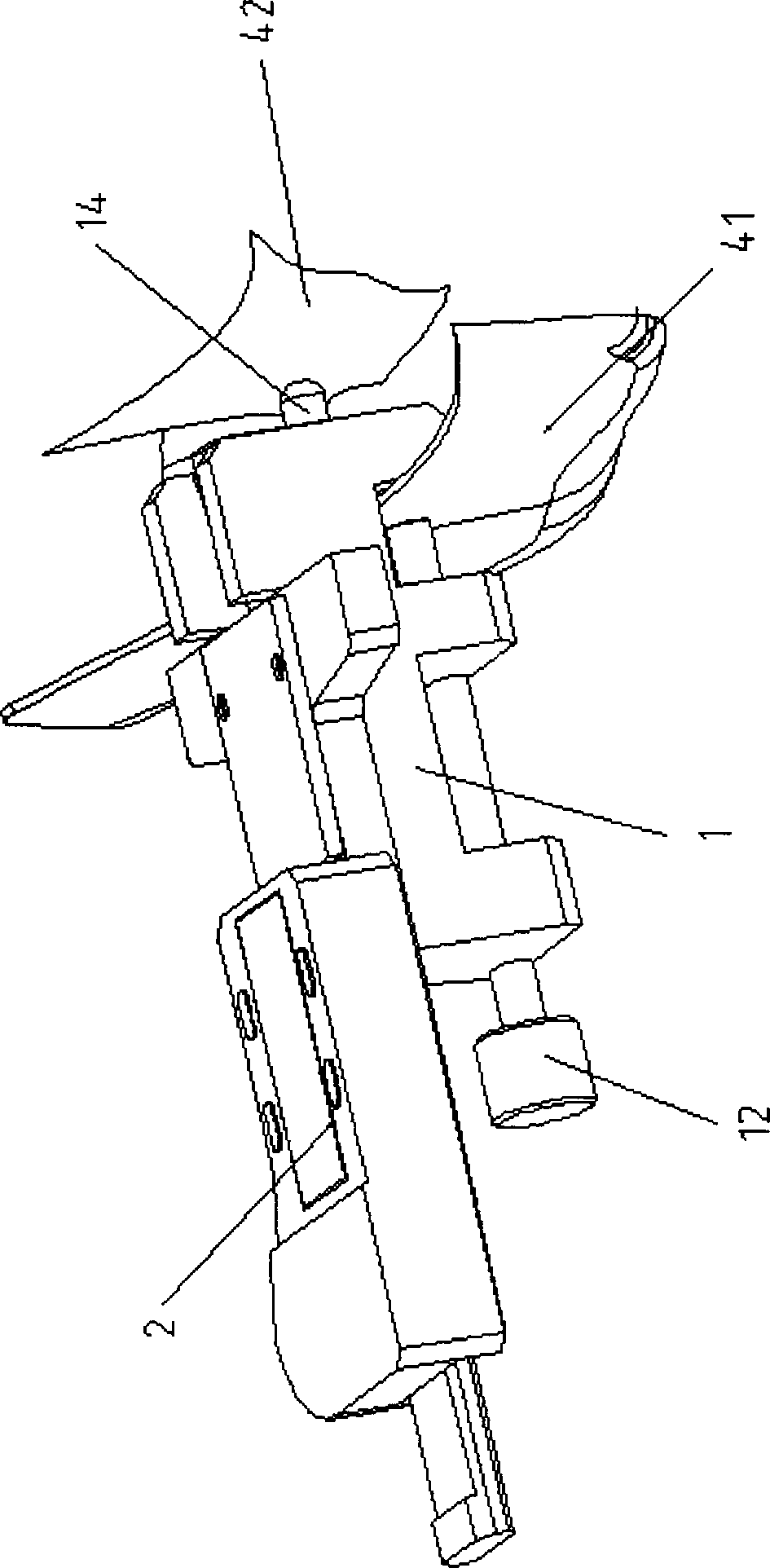

[0019] Such as figure 1 As shown, a notch detection mechanism includes a positioning pressing block 1, a dial indicator 2 and a zero-setting block 3, and the dial indicator is longitudinally fixed on one side of the positioning pressing block; the positioning pressing block The other side protrudes outwards to form two parallel spaced lugs 11, and another tightening screw 12 is provided, which is connected to the two lugs through threaded engagement, and the axis of the tightening screw is in line with the hundred The axis direction of the measuring head of the sub-meter is parallel; the one end of the measuring head of the said positioning pressing block is close to the dial indicator and continues to form two spaced positioning ends 13 towards its other side; the said positioning pressin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com