Hanging-type electric displacement measuring device

An electric displacement and suspension technology, applied in the direction of measuring devices, instruments, etc., can solve the problems of inability to measure the internal displacement of the pile body, the transmission of multi-segment superposition errors, and the inability to recover the fixed instrument, so as to achieve simple and improved displacement measurement work. The effect of repeated service life, reduced difficulty and workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

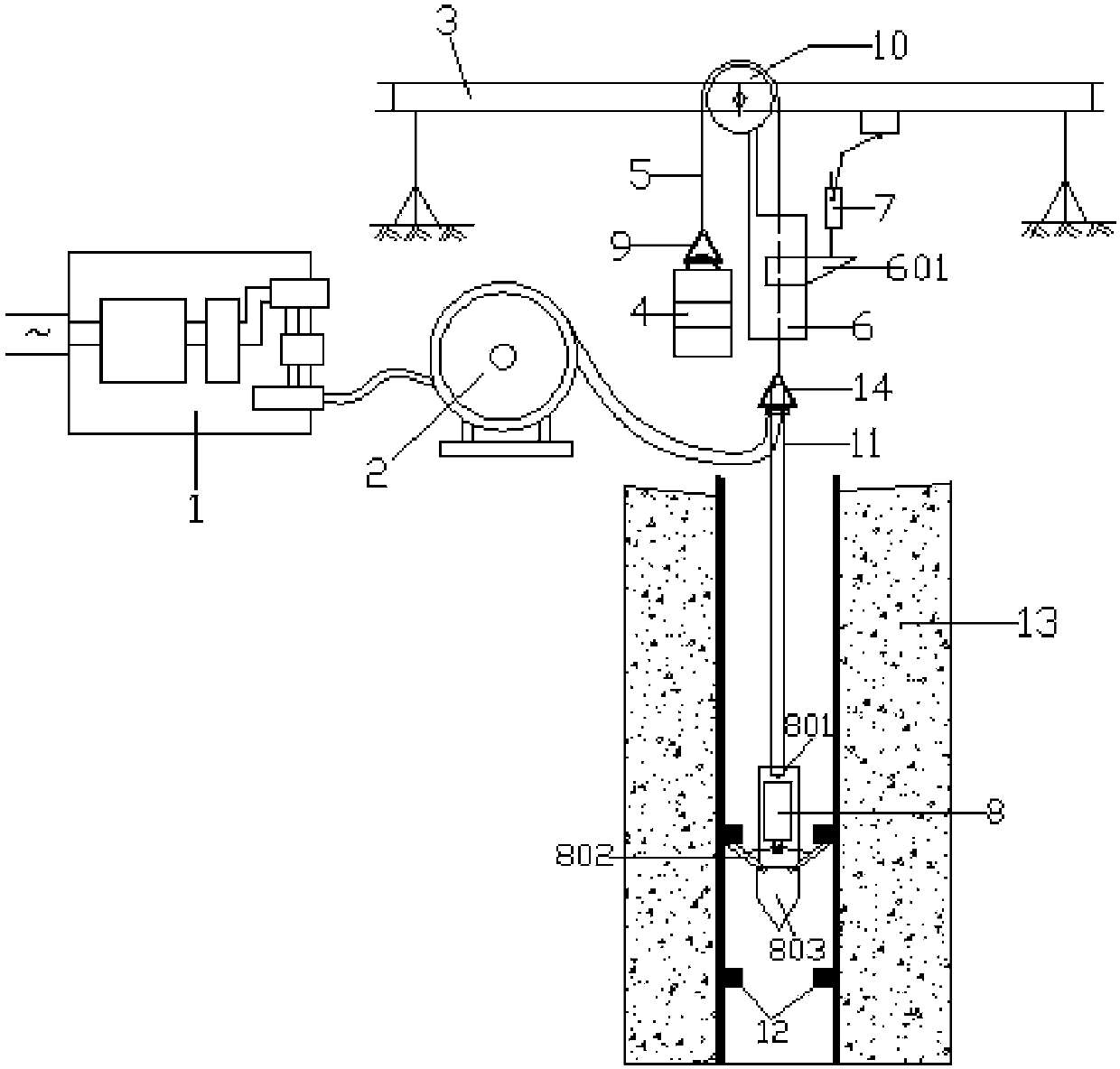

[0015] Such as figure 1 As shown, a suspension type electric displacement measuring device of the present invention includes a power converter 1, a displacement cable reel 2, a reference beam 3, a counterweight 4, a steel strand 5, a sliding meter 6, and a displacement sensor 7 , measuring instrument 8, first safety buckle 9, fixed pulley 10, cable 11 and second safety buckle 14. The power converter 1 is located beside the displacement cable reel 2 . The cable 11 consists of two wires and a steel strand. One end of the cable 11 is wound on the displacement cable reel 2 , and the other end of the cable 11 passes through the second safety buckle 14 and is connected to the tail of the measuring instrument 8 . The fixed pulley 10 is fixedly connected on the reference beam 3 . The steel strand 5 is wound on the fixed pulley 10 . The two ends...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com