Freezing-thawing test machine

A testing machine, freeze-thaw technology, applied in the field of freeze-thaw testing machine, can solve the problems of long refrigeration time, energy waste, etc., and achieve the effect of saving cost, reducing startup frequency and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

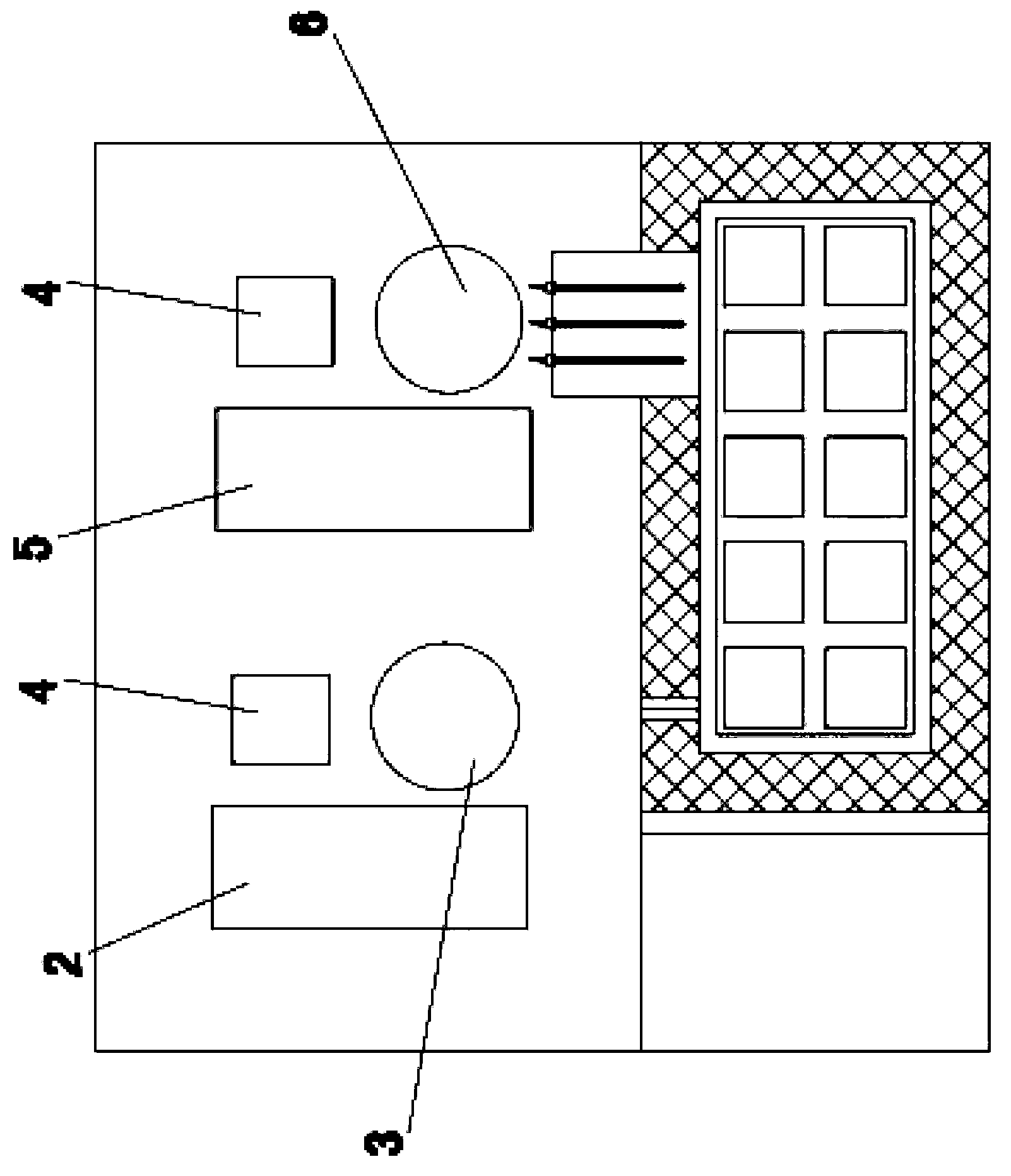

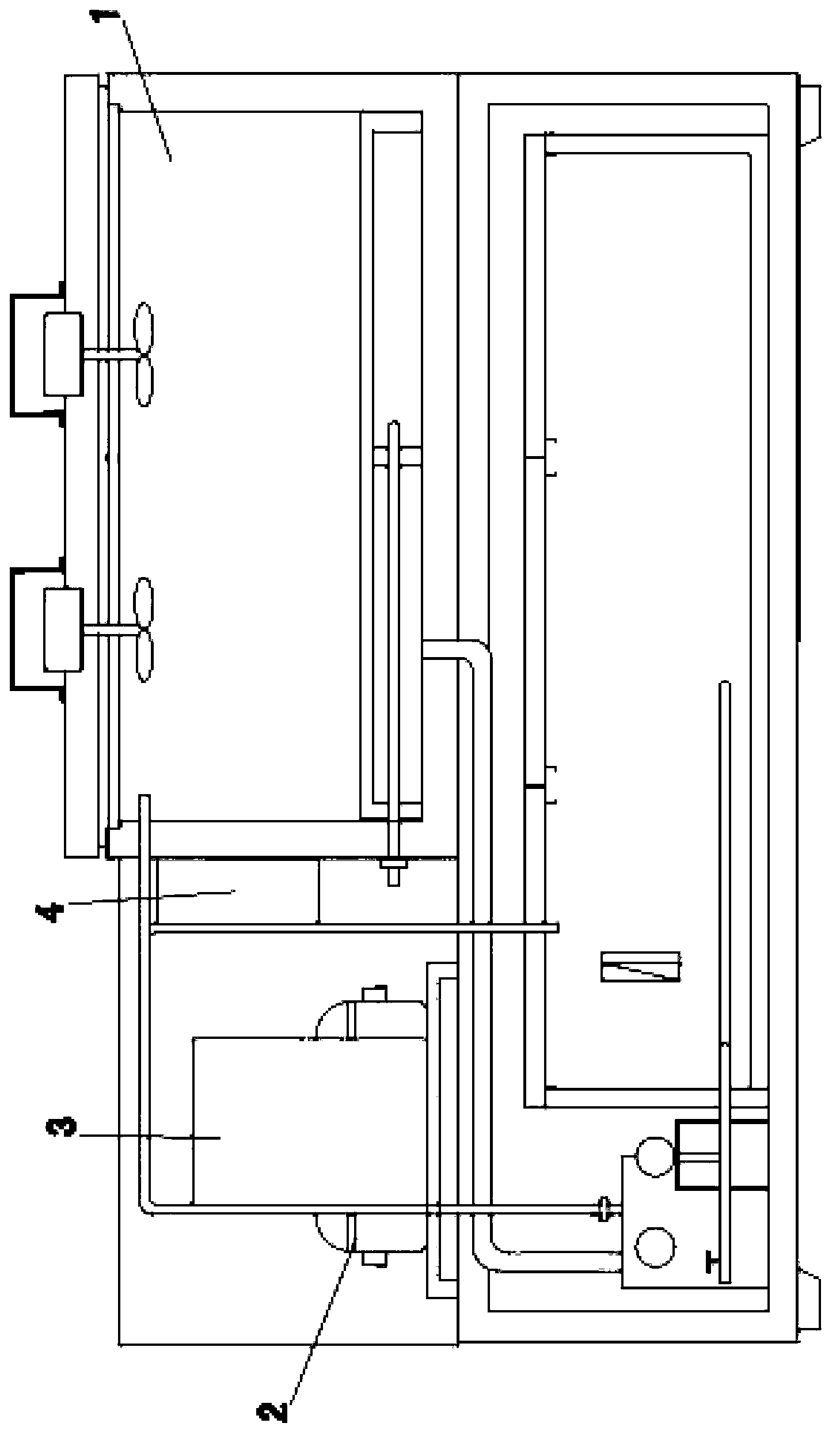

[0014] Such as Figure 1~3 Shown, a kind of freeze-thaw testing machine comprises test piece case 1, control cabinet and refrigeration system; Described control cabinet is positioned at the side of described test piece case 1; Side; the refrigeration system includes a first sub-refrigeration system and a second sub-refrigeration system that operate independently of each other; the first sub-refrigeration system includes a first compressor 2, a first condenser 3 and a plate heat exchanger 4; The second sub-refrigeration system includes a second compressor 5 , a second condenser 6 and a plate heat exchanger 4 ;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com