Adjusting device for verticality and separation distance between shot and imaging chip

A technology of imaging chip and adjustment device, applied in installation, optics, instruments, etc., can solve the problems of affecting imaging effect, inability to adjust the verticality back focal length, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

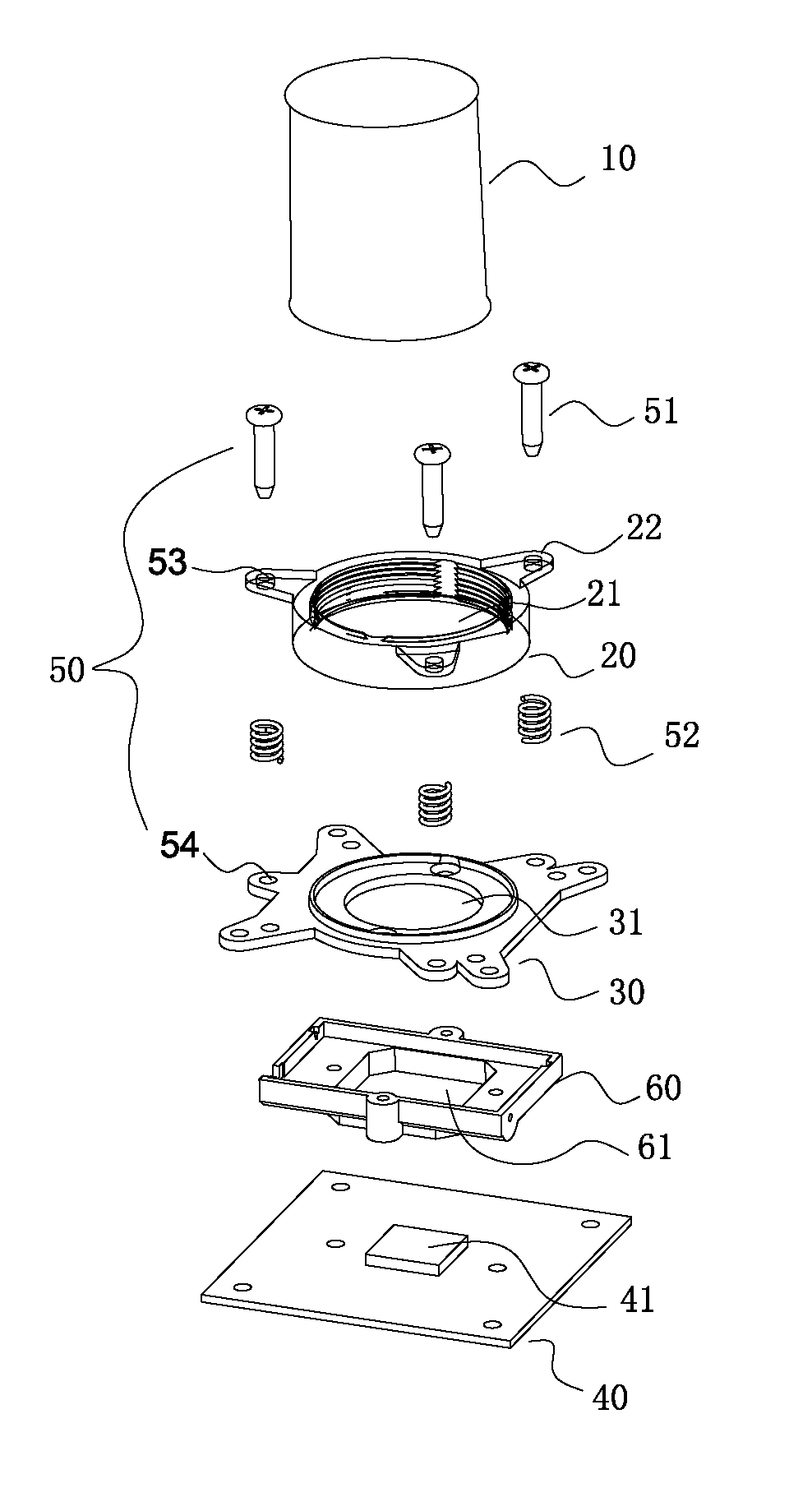

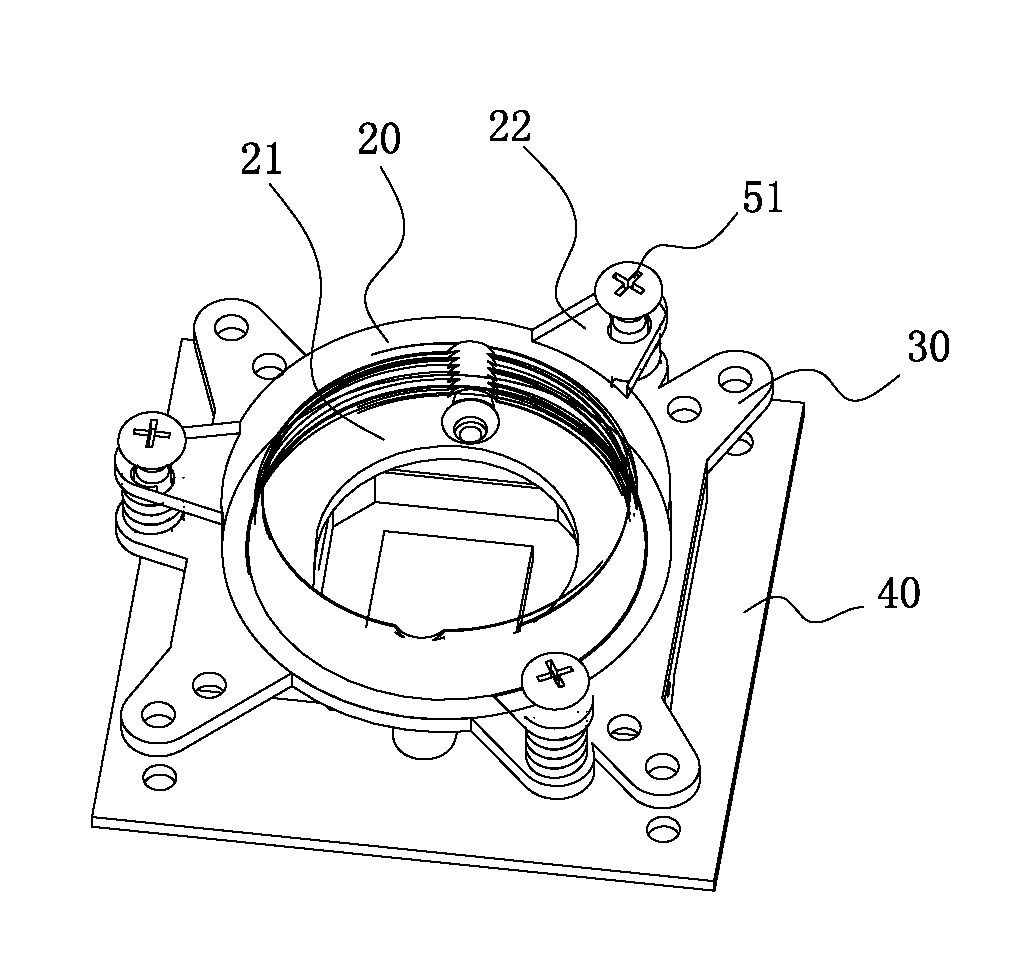

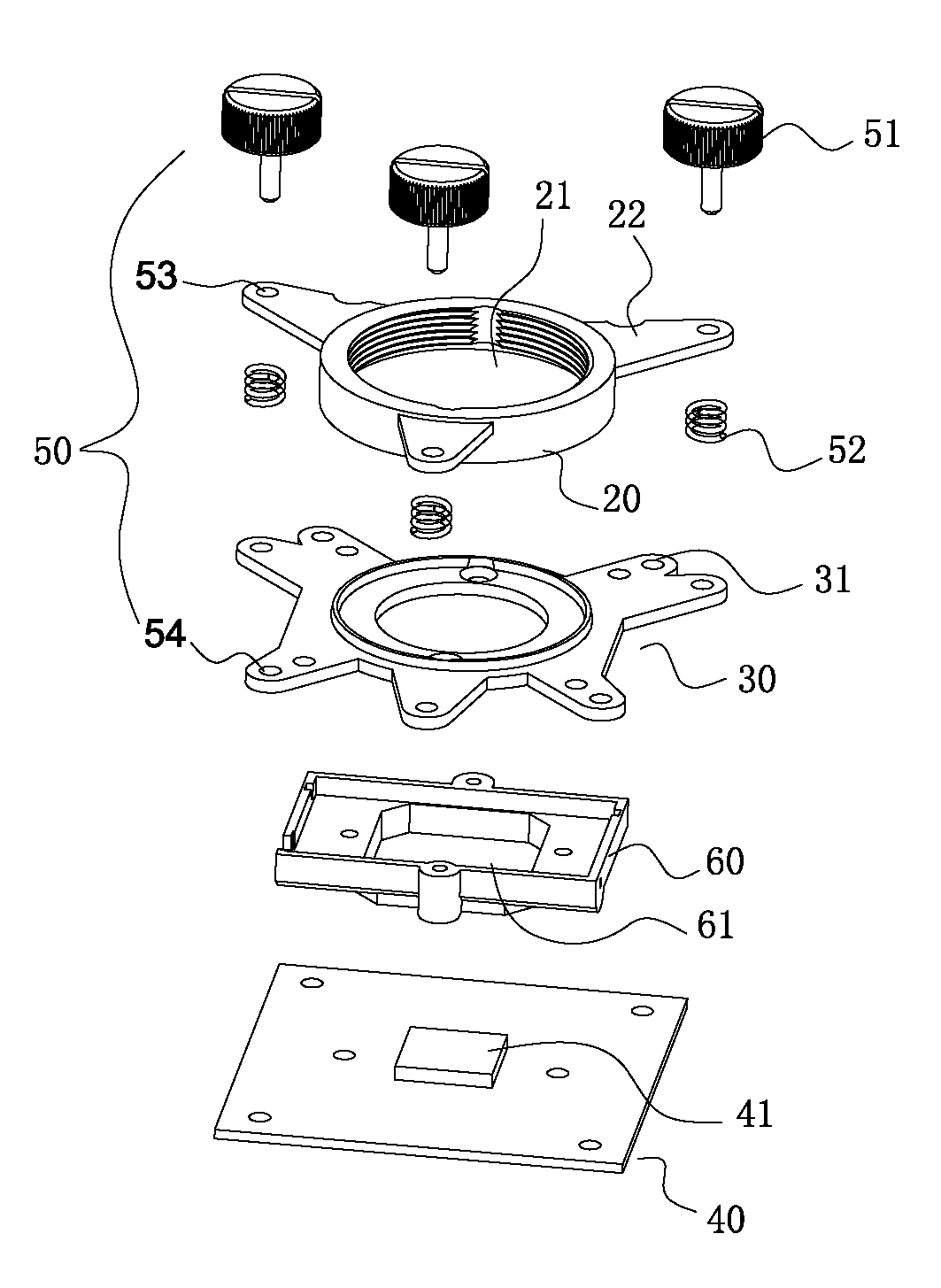

[0026] Such as Figure 1-6 As shown, a device for adjusting the verticality and spacing between the lens and the imaging chip includes a lens 10, a lens holder 20, a lens holder bracket 30 and a PCB board 40 with an imaging chip 41, and the middle of the lens holder 20 is circular Through hole 21, the lens 10 is vertically inserted and fixed on the circular through hole 21 in the middle of the lens holder 20; there is a through hole 31 in the middle of the lens holder bracket 30, and the lens holder bracket 30 and the PCB board 40 with the imaging chip 41 are fixedly connected to form Bracket fixing assembly; the lens holder 20 and the bracket fixing assembly are movably connected by at least three sets of helical elastic adjustment mechanisms 50, and the helical elastic adjustment mechanisms 50 include adjustment screws 51, elastic elements 52, and the first connection hole on the lens holder 20 53 and the second connecting hole 54 on the bracket fixing assembly, any connecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com