Method of correcting of stranded wire equipment

A twisted wire equipment, first wire technology, applied in electrical components, circuits, cable/conductor manufacturing, etc., can solve problems such as easy failure, hidden dangers for users, and a large amount of investment, to ensure that the resistivity remains unchanged and the resistance to resistance is guaranteed. The effect of pulling performance and reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

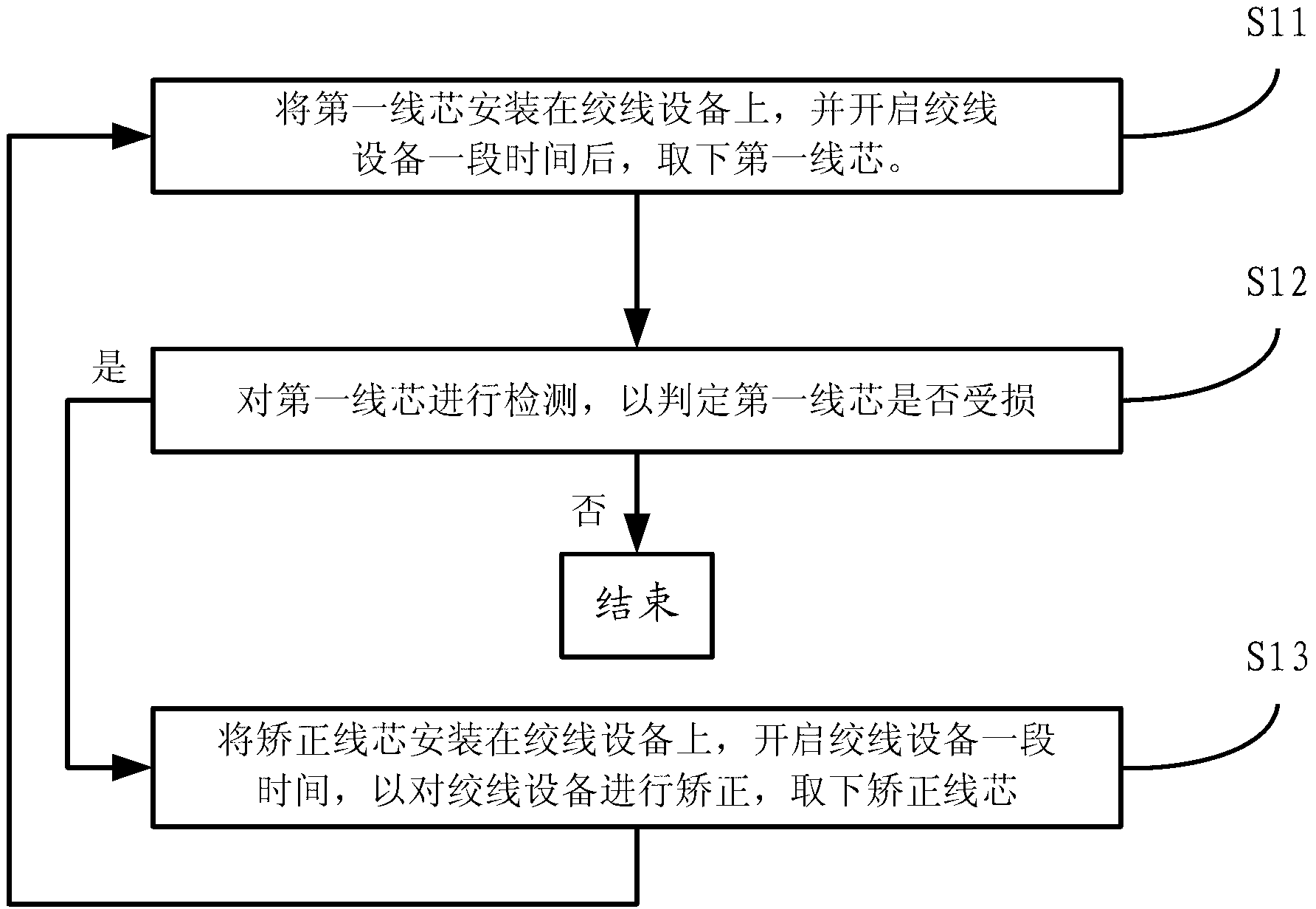

[0014] A method for rectifying a twisted wire device is proposed, and the twisted wire device is used for twisting a first wire core, comprising the steps of:

[0015] S11. Install the first wire core on the twisted wire device, and after turning on the twisted wire device for a period of time, remove the first wire core.

[0016] Specifically, since the damage to the first core is mainly due to some punctures at the contact position between the first core and the stranding equipment, if the stranding equipment is directly used to twist the first core, the core will be damaged. Cause a permanent damage, not only will affect its tensile strength, but also affect its resistivity, before using the stranding equipment to strand the first core, first, install the part of the first core to be twisted on the strand On the wire equipment, after the twisted wire equipment is turned on for a period of time, the thorns on the twisted wire equipment will cause damage to the surface wall o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com