A data processing method for the stretching coefficient of printed board drill tape

A tensile coefficient and data processing technology, which is applied in the field of data processing of tensile coefficient of printed board drilling tape, can solve the problems of high cost, waste of cost, troublesome control of drilling accuracy, etc., and achieve the effect of saving cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

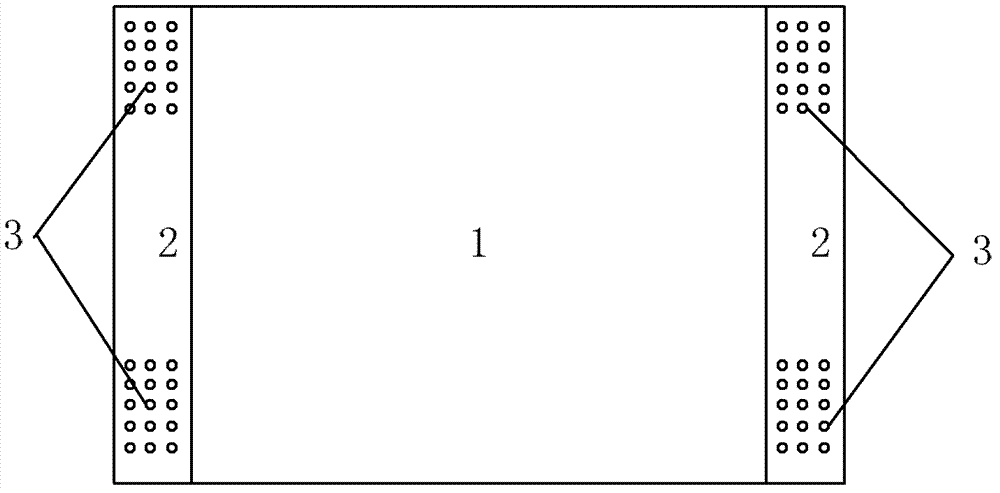

[0015] Such as figure 1 As shown, the printed board of the present invention includes a unit board 1 and a test strip 2 , and the test strip 2 is located on both sides of the unit board 1 . During engineering production, we add some test holes 3 at the reasonable positions of the four corners outside the production data and add welding rings on the inner and outer layers. During production, we confirm the tensile coefficient of the drill tape by drilling test holes; the whole process can be divided into Three steps to achieve.

[0016] A data processing method for the stretching coefficient of a printed board drill tape, the specific method steps are:

[0017] Step 101. On the four corners of the test strip 2, drill one-third of the total number of drilled holes with a ratio of 1:1, and compare the deviation of the hole position, so as to p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com