Hot dog shaping assembly and hot dog shaped by using hot dog shaping assembly

A technology for heating components and hot dogs, applied in the directions of baking cans, oil/fat baking, etc., can solve the problems of underutilization, long time consumption, waste of time T or T' for frying, etc., and achieve full and effective use of time. , the effect of reducing hazards and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

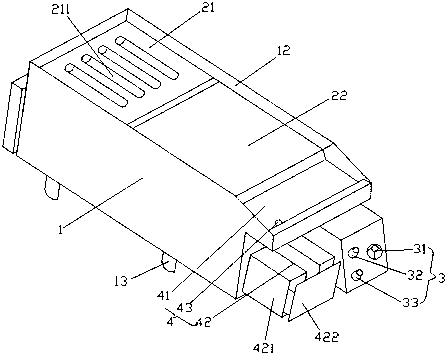

[0020] refer to figure 1 As shown, a hot dog shaping assembly provided by the present invention is installed on the working platform 22 of the grate 1, and the hot dog shaping assembly includes at least one detachable shaping block 21 installed on the working platform 22, and the Each shaping block 21 is provided with at least one shaping groove 211 , and the hot dog to be shaped is shaped in the shaping groove 211 . The shaping groove 211 of the present invention has a width of 3-5 cm, a length of 10-25 cm, and a depth of 1-3 cm.

[0021] Preferably, the furnace frame 1 includes a frame body, a surrounding board 12 and a plurality of legs 13 . The surrounding board 12 is connected with the upper surface of the frame body on three sides and is protrudingly arranged on the frame body; the surrounding board 12 surrounds the working platform 22 and has an opening for operation; Of course, the support 13 can be a rubber foot or a roller.

[0022] As a preference, the shaped blo...

Embodiment 2

[0026] The present invention also provides a hot dog shaped according to the above-mentioned hot dog shaping assembly, including bread, which also includes food disposed in the bread; wherein, the food is shaped by the shaping groove 211 of the hot dog shaping assembly, and the shaped The food is placed in the bread, and the bread is shaped into a hot dog by the shaping groove 211 of the hot dog shaping assembly.

[0027] Wherein, according to different shapes of the shaping groove 211, the shape of the hot dog includes strip shape, circle shape or irregular shape.

[0028] Preferably, the food in the bread is selected from one or more of eggs, shrimp paste, fish paste, and fabrics.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com