Preparation method of manganese dioxide nanosheet/carbon nanotube core-shell structure denitration catalyst

A technology of denitrification catalyst and carbon nanotubes, which is applied in the field of nanomaterial preparation and environmental protection, can solve the problems that active component particles are easy to agglomerate and it is difficult to ensure the dispersion of active components, and achieve simple preparation process, good low-temperature denitrification performance, easy The effect of the operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

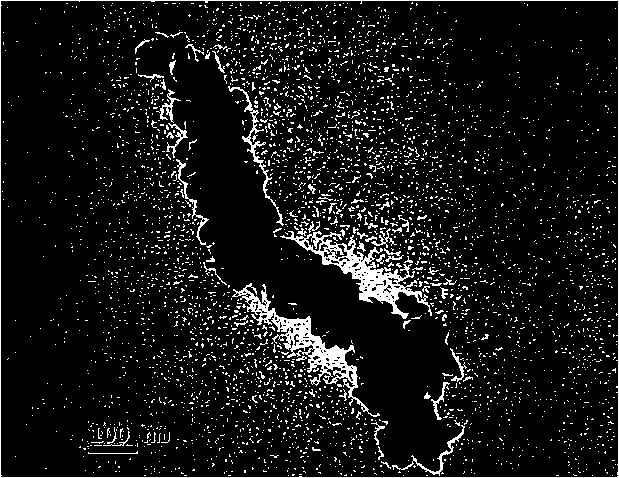

Image

Examples

Embodiment 1

[0020] Dissolve 0.1 g of potassium permanganate in 250 mL of deionized water to form a concentration of 2.5×10 -3 mol / L potassium permanganate solution, then add 0.2 g single-walled carbon nanotubes into the above solution, ultrasonically disperse for 0.5 h, wherein the mass ratio of potassium permanganate:carbon nanotubes is 0.9:1, then add hydrochloric acid In the above solution, adjust the pH value to 2, raise the temperature of the above solution to 60°C, reflux for 2 h under magnetic stirring, separate after cooling to room temperature, wash, and then dry to obtain the manganese dioxide nanosheet / carbon nanosheet Tube denitrification catalyst. The catalyst has a core-shell structure, the manganese dioxide nano-sheet is the shell, the carbon nano-tube is the core, and the manganese dioxide nano-sheet is uniformly coated on the surface of the carbon nano-tube.

[0021] Catalyst evaluation: Grind and sieve the prepared catalyst, take 20-40 mesh particles, put them into a f...

Embodiment 2

[0023] Dissolve 0.4 g of potassium permanganate in 500 mL of deionized water to form a concentration of 5 × 10 -3 mol / L potassium permanganate solution, then add 0.1 g multi-walled carbon nanotubes into the above solution, ultrasonically disperse for 1 h, wherein the mass ratio of potassium permanganate:carbon nanotubes is 7.3:1, then add oxalic acid In the above solution, adjust the pH value to 3, raise the temperature of the above solution to 70°C, reflux for 3 h under magnetic stirring, separate after cooling to room temperature, wash, and then dry to obtain the manganese dioxide nanosheet / carbon nanosheet Tube denitrification catalyst. The catalyst has a core-shell structure, the manganese dioxide nano-sheet is the shell, the carbon nano-tube is the core, and the manganese dioxide nano-sheet is uniformly coated on the surface of the carbon nano-tube.

[0024] Catalyst evaluation: Grind and sieve the prepared catalyst, take 20-40 mesh particles, put them into a fixed-bed ...

Embodiment 3

[0026] Dissolve 1 g of potassium permanganate in 1000 mL of deionized water to form a concentration of 6 × 10 -3 mol / L potassium permanganate solution, then add 1.4 g of multi-walled carbon nanotubes into the above solution, ultrasonically disperse for 1.5 h, wherein the mass ratio of potassium permanganate:carbon nanotubes is 1.3:1, then add acetic acid In the above solution, adjust the pH value to 4, raise the temperature of the above solution to 80°C, reflux for 4 h under magnetic stirring, separate after cooling to room temperature, wash, and then dry to obtain the manganese dioxide nanosheet / carbon nanosheet Tube denitrification catalyst. The catalyst has a core-shell structure, the manganese dioxide nano-sheet is the shell, the carbon nano-tube is the core, and the manganese dioxide nano-sheet is uniformly coated on the surface of the carbon nano-tube.

[0027] Catalyst evaluation: Grind and sieve the prepared catalyst, take 20-40 mesh particles, put them into a fixed-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com