Outer wind shield for vehicle

A technology for external windshields and vehicles, which is applied in railway car bodies, railway car body components, climate sustainability, etc. to improve the airflow environment, reduce aerodynamic forces, and improve disturbances.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

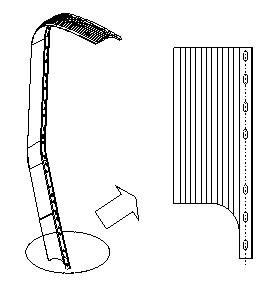

[0015] Such as figure 1 As shown, open the guide slot at the bottom of the outer windshield.

[0016] Due to the uneven track and complex equipment at the bottom of the car, the airflow at the bottom of the car body is the most unstable, and the external windshield tends to turn over and tear from the bottom of the car. Opening the diversion groove at the bottom of the outer windshield can increase the space for airflow diversion, which is beneficial to the pressure relief of the airflow under the car, thereby reducing the impact of the airflow disturbance at the bottom of the car on the outer windshield, and improving the tearing of the outer windshield at the bottom of the car Condition. Of course, the outer windshield of the present invention is not limited to rail vehicles.

Embodiment 2

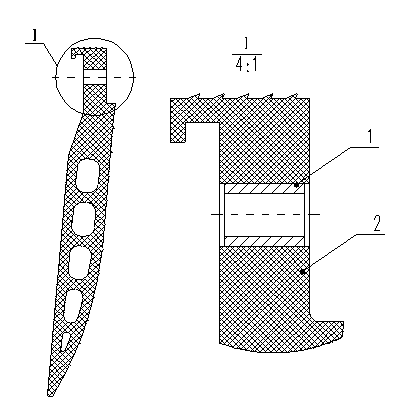

[0018] Such as figure 2 As shown, add a protective steel sleeve inside the mounting hole.

[0019] After adding the protective steel sleeve, the stress form of the mounting hole is changed from the line contact between the rubber and the bolt thread to the line contact between the bolt and the steel sleeve, and then the surface of the steel sleeve is in contact with the rubber surface of the mounting hole, which improves the bearing capacity of the mounting hole. It reduces the stress concentration of the mounting hole, thereby preventing the rubber from deforming and tearing under the interaction with the bolt.

[0020] At the same time, due to the support of the protective steel sleeve, the bending strength of the mounting hole position is also correspondingly improved, which can effectively prevent the bending deformation of the outer windshield under the action of a large external force.

Embodiment 3

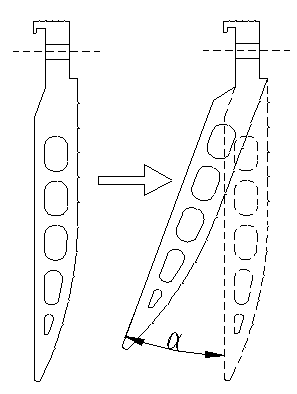

[0022] Such as image 3 As shown, the wing plate of the outer windshield is designed as an inclined structure. Preferably, it is inwardly inclined at α° with the direction of the vehicle body. The size of α is based on the aerodynamic calculation and analysis that can effectively reduce the pressure difference on both sides of the outer windshield. .

[0023] The study found that when the inclination angle α is not less than 2° and the vehicle speed is at medium or high speed, the pressure difference on both sides of the outer windshield can be effectively reduced through aerodynamic calculation and analysis, thereby reducing the valgus force of the airflow on the outer windshield , especially to reduce the probability of the outer windshield turning over when the vehicle is running at high speed, and finally achieve the purpose of preventing the outer windshield from tearing. This patent has implemented 2°, 5°, and 10° inclination angles, preferably 5°. At this time, the str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com