Air suction type high-speed precision seed metering device with auxiliary seed-filling seed disc

A seed metering and air-suction technology, applied in the field of air-suction seed metering, can solve the problems of unclean seed unloading, low operation speed, incomplete seed clearing, etc. The effect of wind pressure and increased working speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

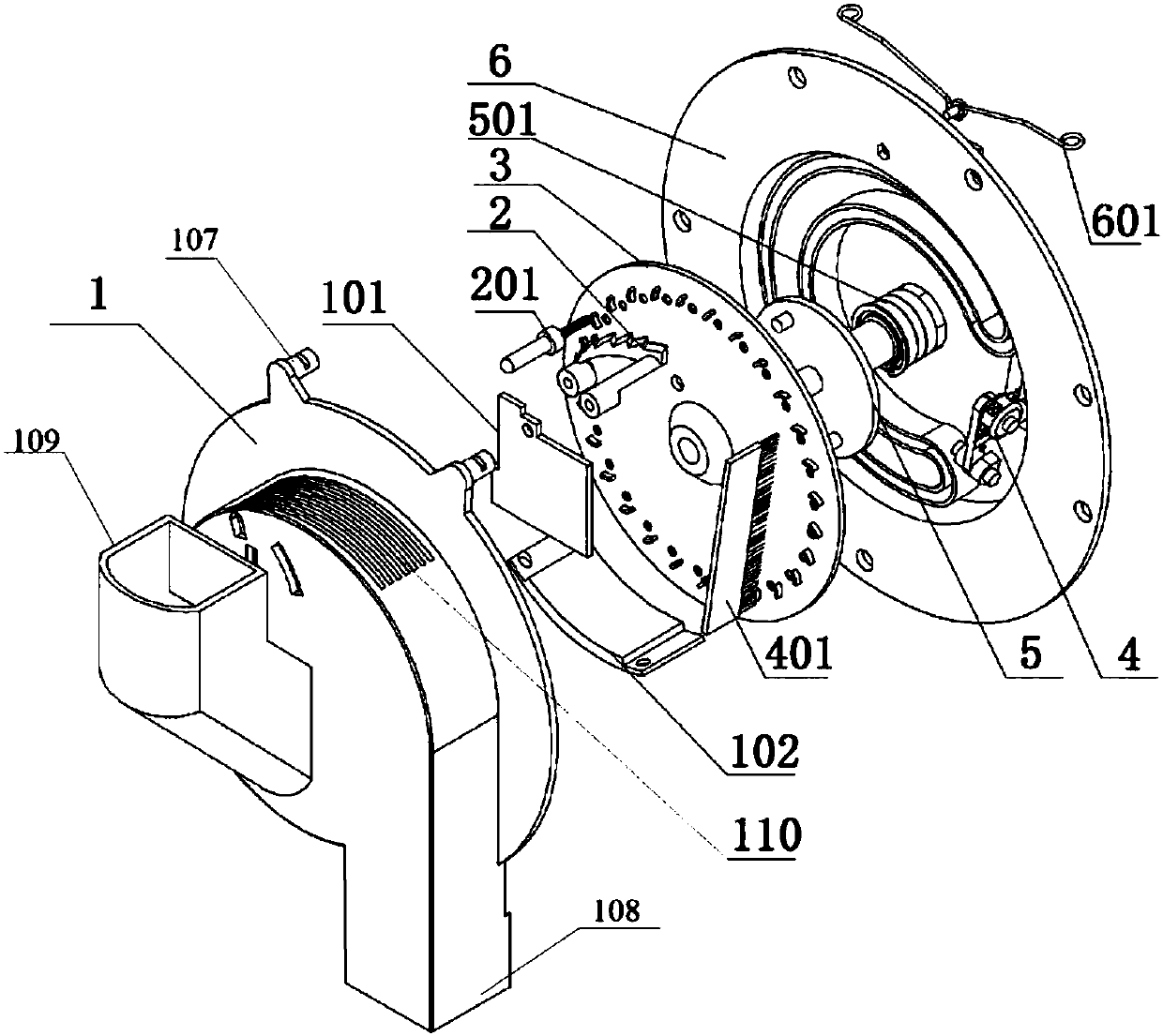

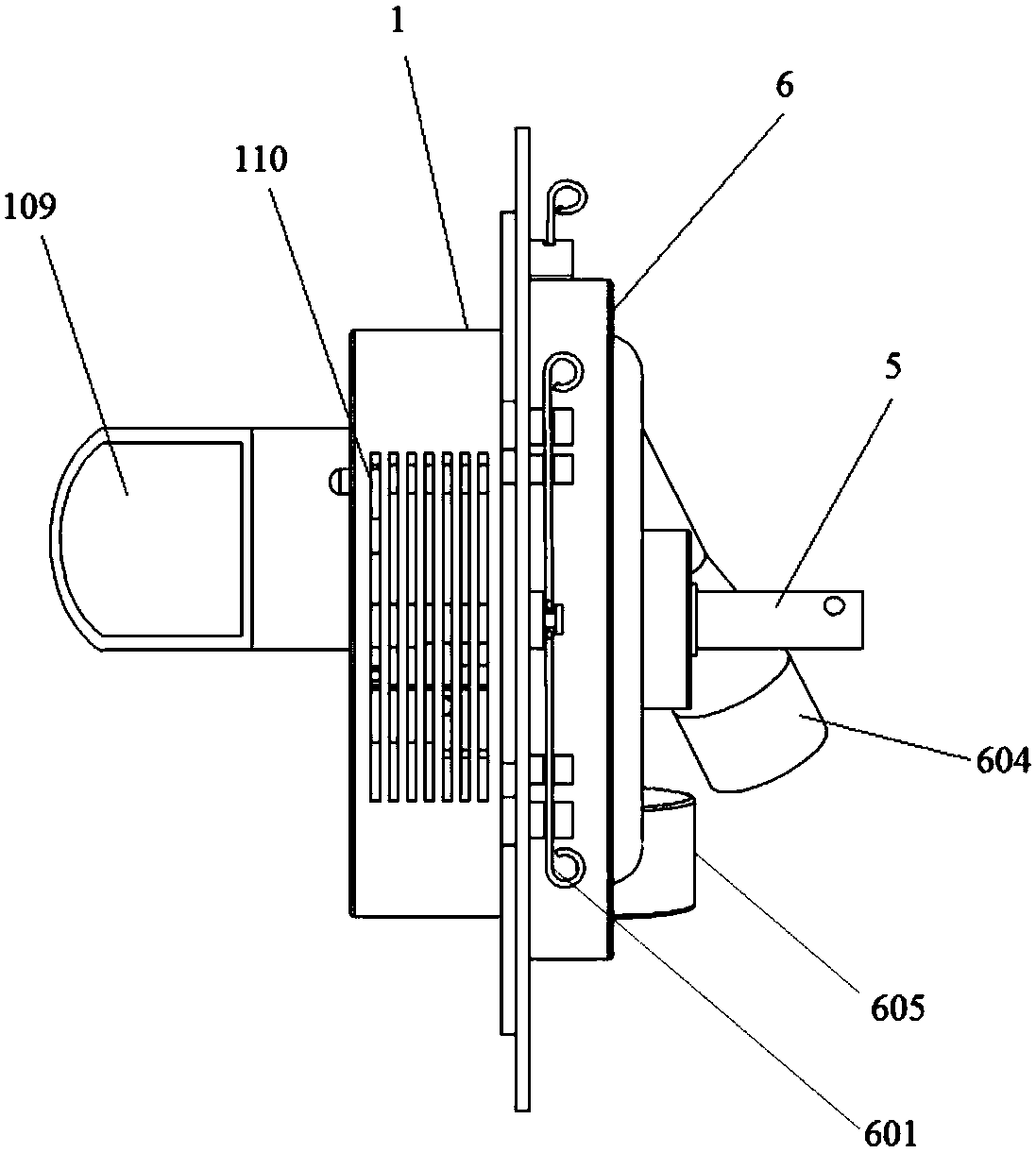

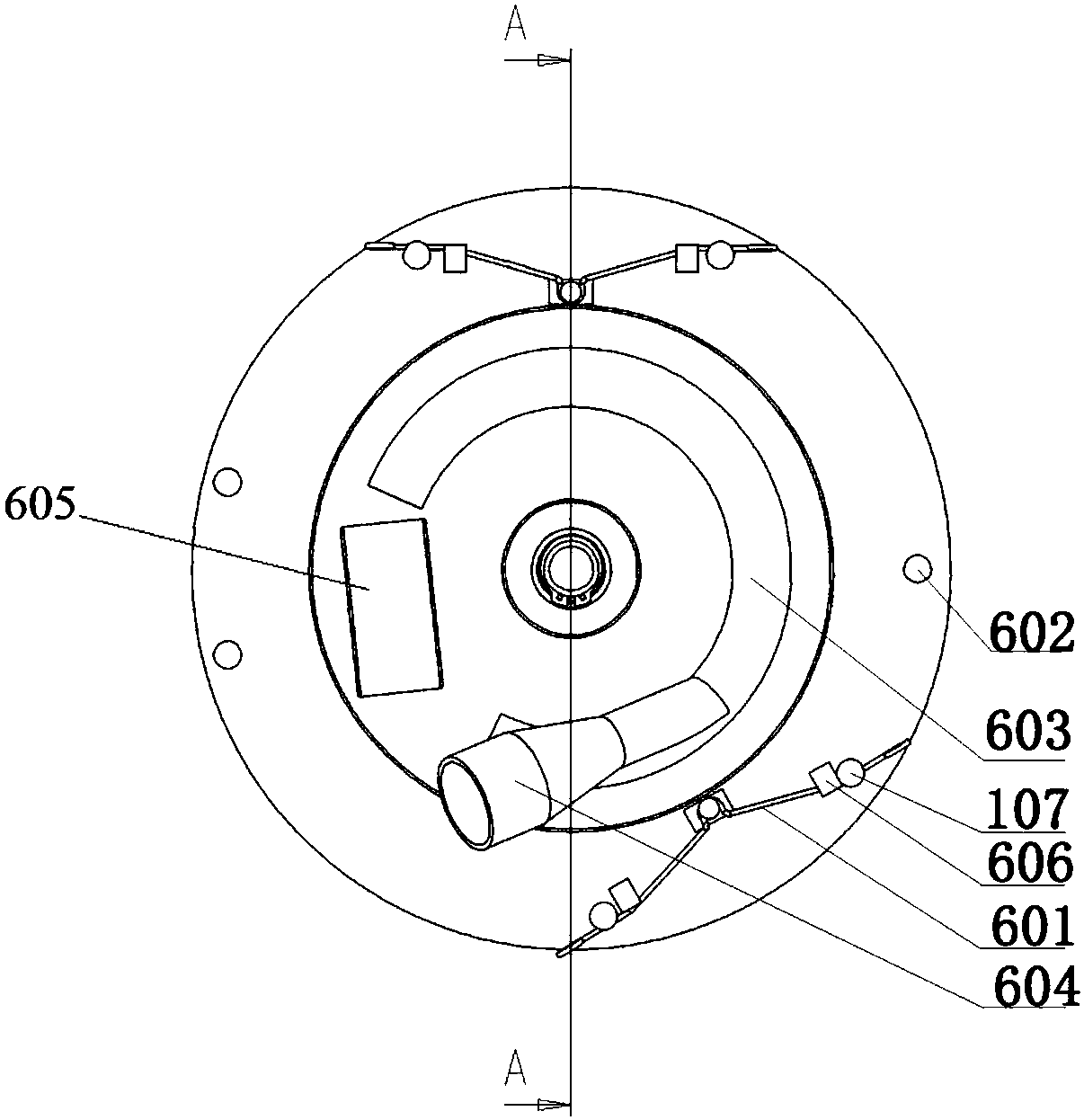

[0052] Such as figure 1 and figure 2 As shown, the air-suction seed metering device of the present invention mainly includes a front housing 1 , a seed clearing mechanism 2 , a seed tray 3 , a seed unloading mechanism 4 , and a rear housing 6 of a transmission mechanism 5 . The seed clearing mechanism 2 is installed on the front housing 1, which can adjust the clearing position. The seed disc 3 is fixed on the transmission mechanism 5, and the seed unloading mechanism 4 is installed on the rear housing 6, which can be in contact with the seed disc 3. The rear housing 6 can be fixedly connected and disassembled with the front housing 1.

[0053] For details, see figure 1 , 4 And 5, the front housing 1 includes a seed layer height adjustment plate 101, a seed unloading baffle plate 102, an adjustment hole 103, a groove 104, a brush adjustment hole 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com