Industrial wastewater treatment system and treatment method based on high-salt wastewater

A technology for high-salt wastewater and industrial wastewater, applied in water/sewage treatment, heating water/sewage treatment, adsorption water/sewage treatment, etc., can solve the problems of reducing high-salt wastewater treatment efficiency, increasing costs, etc., to increase exposure area, COD reduction, and high energy efficiency ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

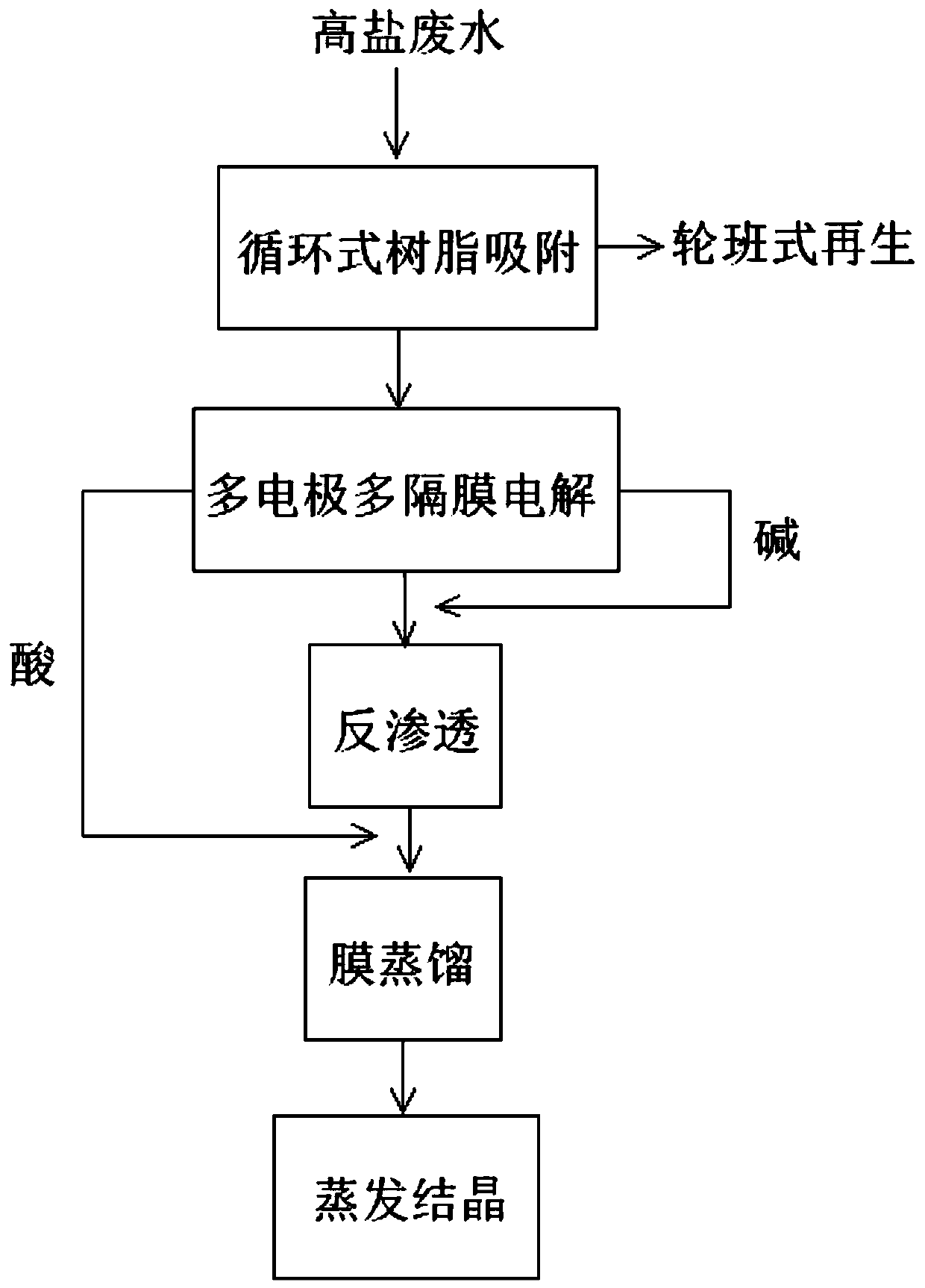

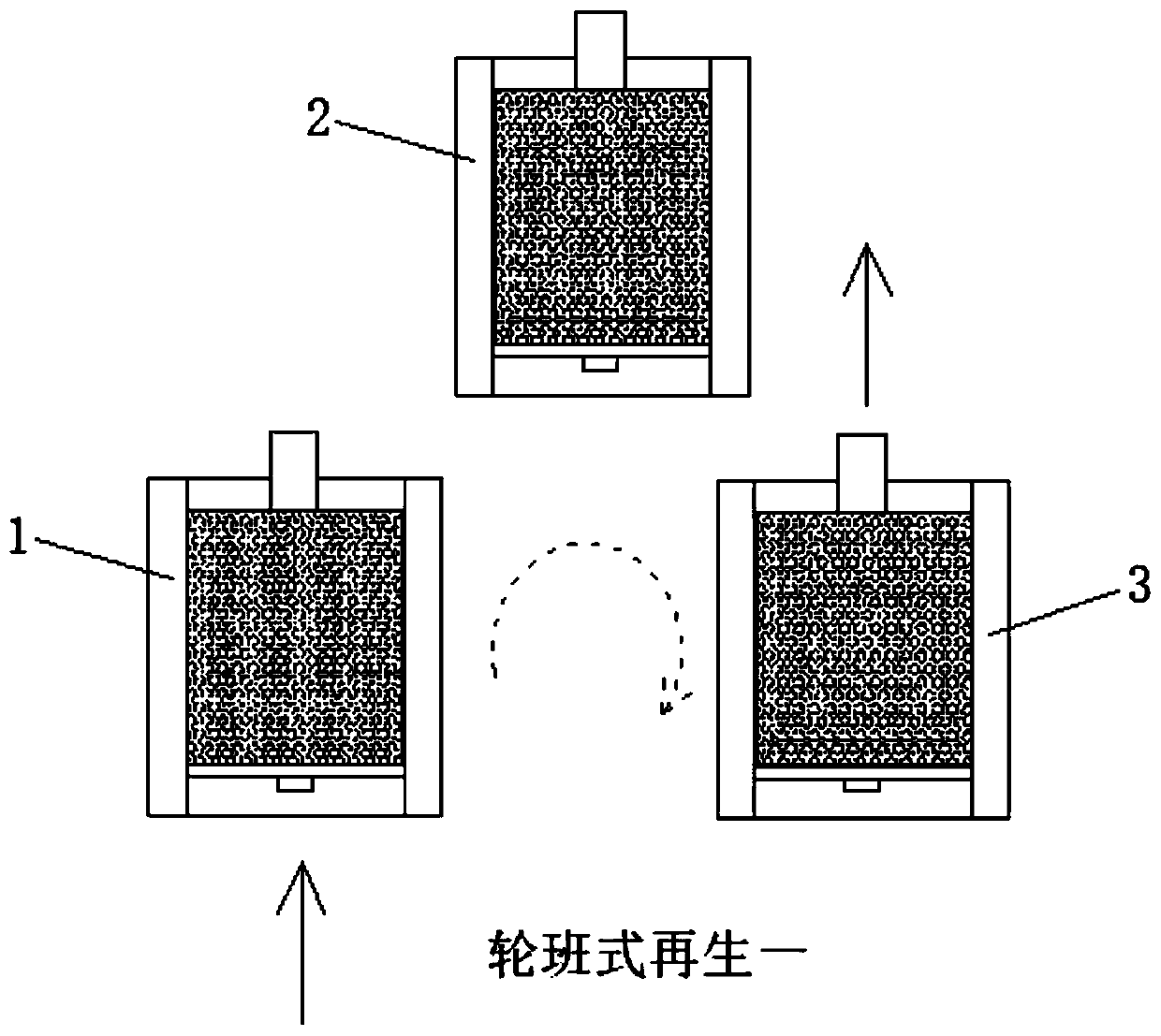

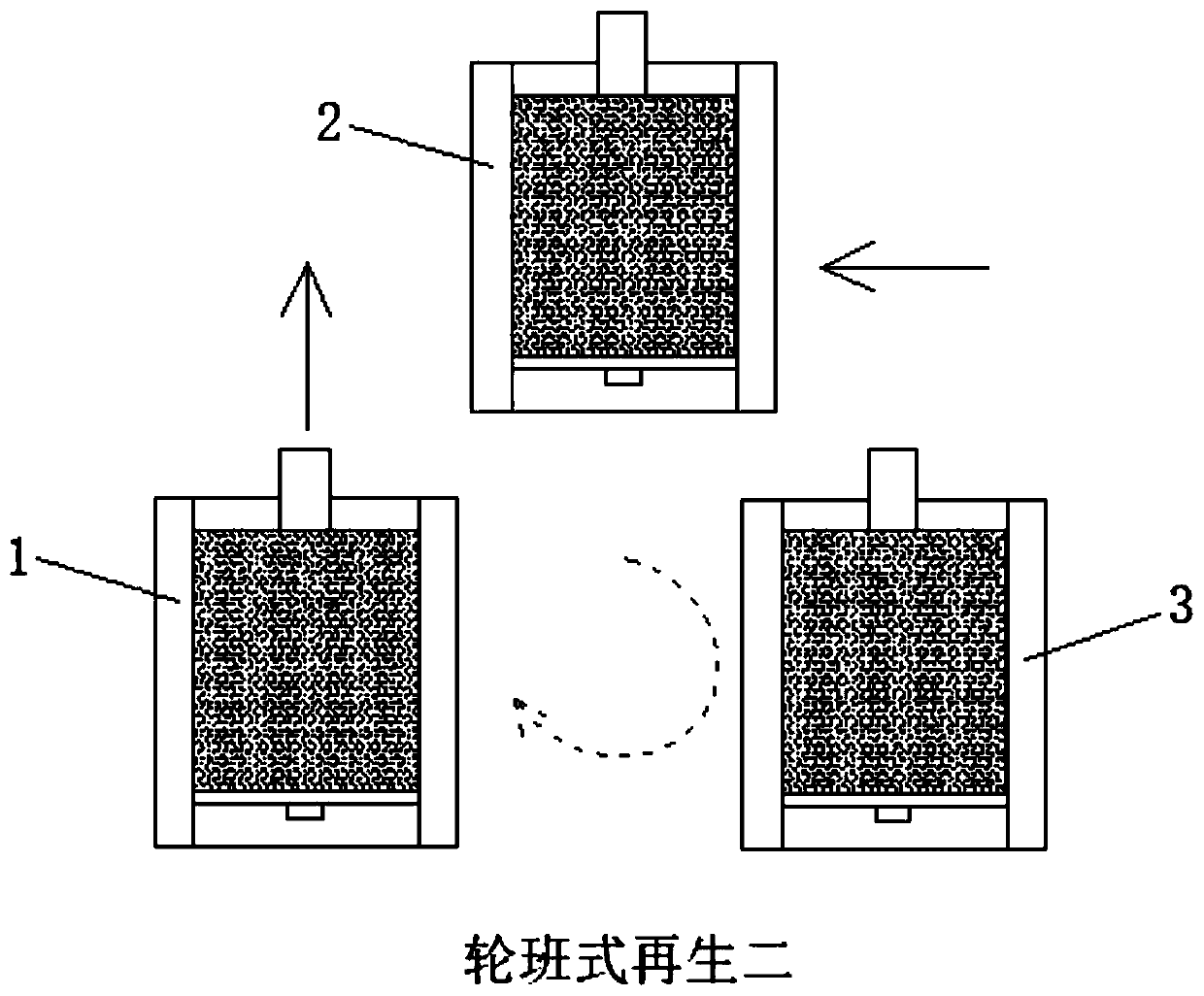

[0051] An industrial wastewater treatment system based on high-salt wastewater, including a cyclic resin adsorption unit, a multi-electrode multi-diaphragm electrolysis unit, a reverse osmosis unit, a membrane distillation unit, and an evaporation crystallization unit. The cyclic resin adsorption unit includes multiple resin adsorption subunits The interior of the resin adsorption sub-unit is filled with renewable resin particles 5. First, resin adsorption is used to remove hardness and a small amount of organic matter in high-salt wastewater, and then multi-electrode and multi-diaphragm electrolysis can be used to remove the salt in high-salt wastewater more thoroughly. Reverse osmosis is used to further concentrate the high-salt wastewater after hardness removal to obtain reverse osmosis product water and reverse osmosis concentrated water. The reverse osmosis concentrated water is further concentrated by membrane distillation to obtain membrane distillation product water and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com