Low-scooter suspension-type bogie

A technology for low-floor vehicles and bogies, which is applied to the installation of bogies, railway car body parts, and axle boxes, and can solve problems such as the difficulty in the design of the car floor surface transmission and running parts, and achieve low center of gravity, guiding performance, and stable operation performance improvement, channel width expansion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

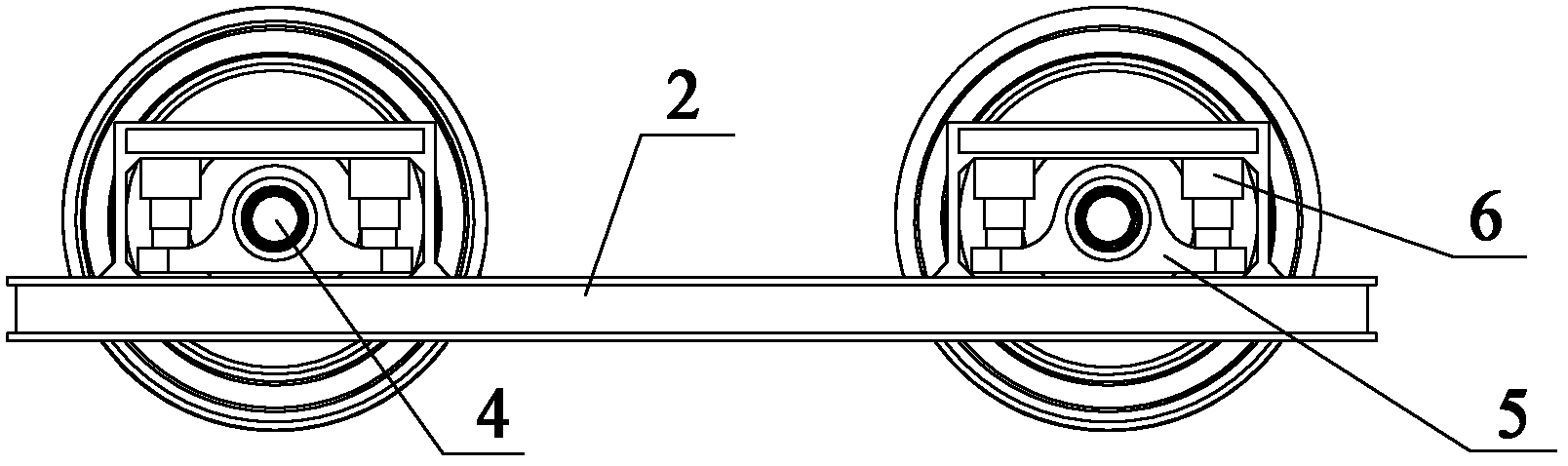

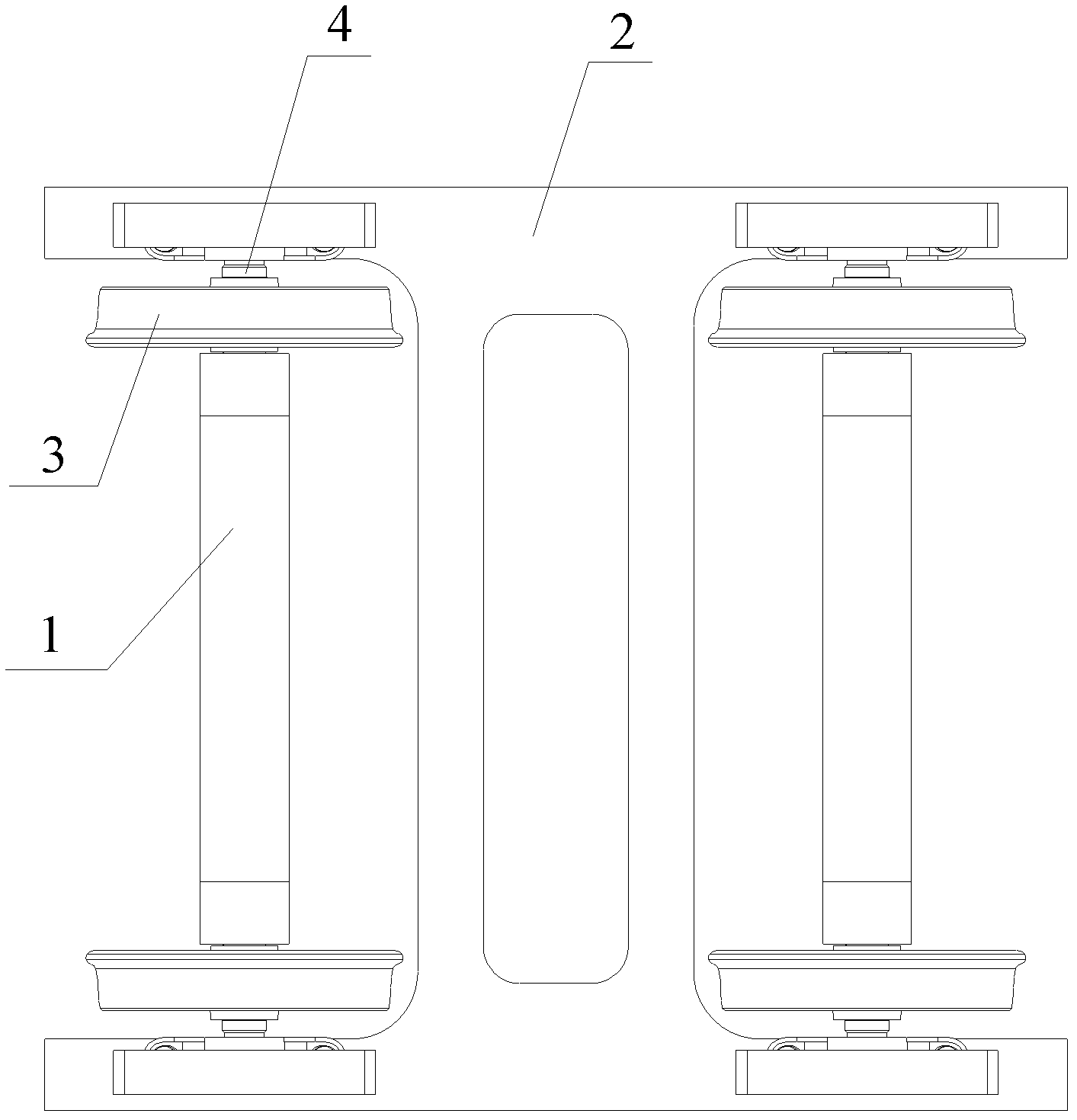

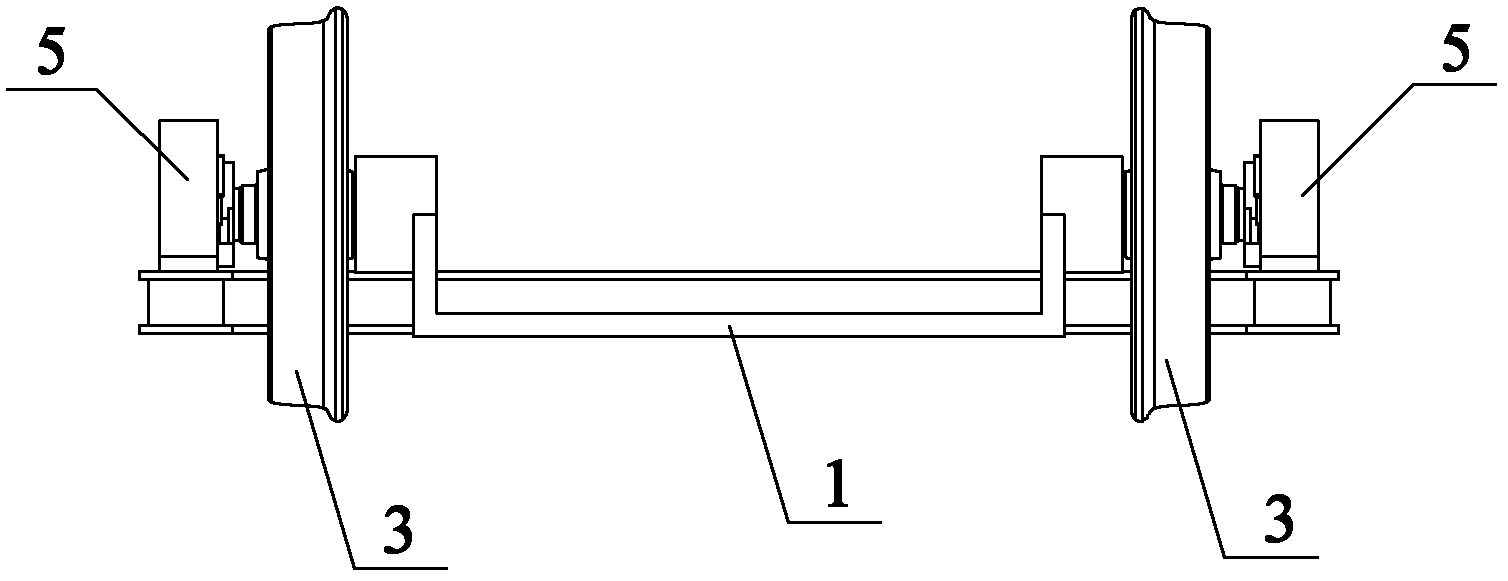

[0023] A suspension bogie for a low-floor vehicle, the structure of which is as follows Figure 1-4 As shown, it includes a crankshaft 1, a frame 2, a wheel 3, an axle 4, an axle box 5, and a series of springs 6. The frame 2 is an H-shaped structure, with two crossbeams in the middle, and two wheel sets 3 with crankshafts, which are respectively connected with the four suspension frames of the frame 2 through the axle box 5, the primary spring 6, and the primary spring 6. The suspension frame 2 is arranged on the spring support of the axle box 5 and on the outside of the wheel 3 .

[0024] The wheels 3 on both sides of the front end of the frame 2 and the crankshaft 1 form an independent wheelset structure with a crankshaft, and the wheels 3 and the crankshaft 1 on both sides of the rear end also form an independent wheelset structure with a crankshaft.

[0025] The bogie of this new structural design uses an independent wheel set structure with a crankshaft, and innovatively...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com