New energy automobile motor V-shaped mounting adjustment device

A new energy vehicle, installation and adjustment technology, applied in the direction of motor vehicles, transportation and packaging, etc., can solve the problems of increased workload, inaccurate control, self-heavy motor, etc., to reduce the input of manpower and material resources, and accurately control the tilt angle , the effect of reducing the number of adjustments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to understand the technical content of the present invention more clearly, the following examples are given in detail. In this case, the same components are provided with the same reference numerals.

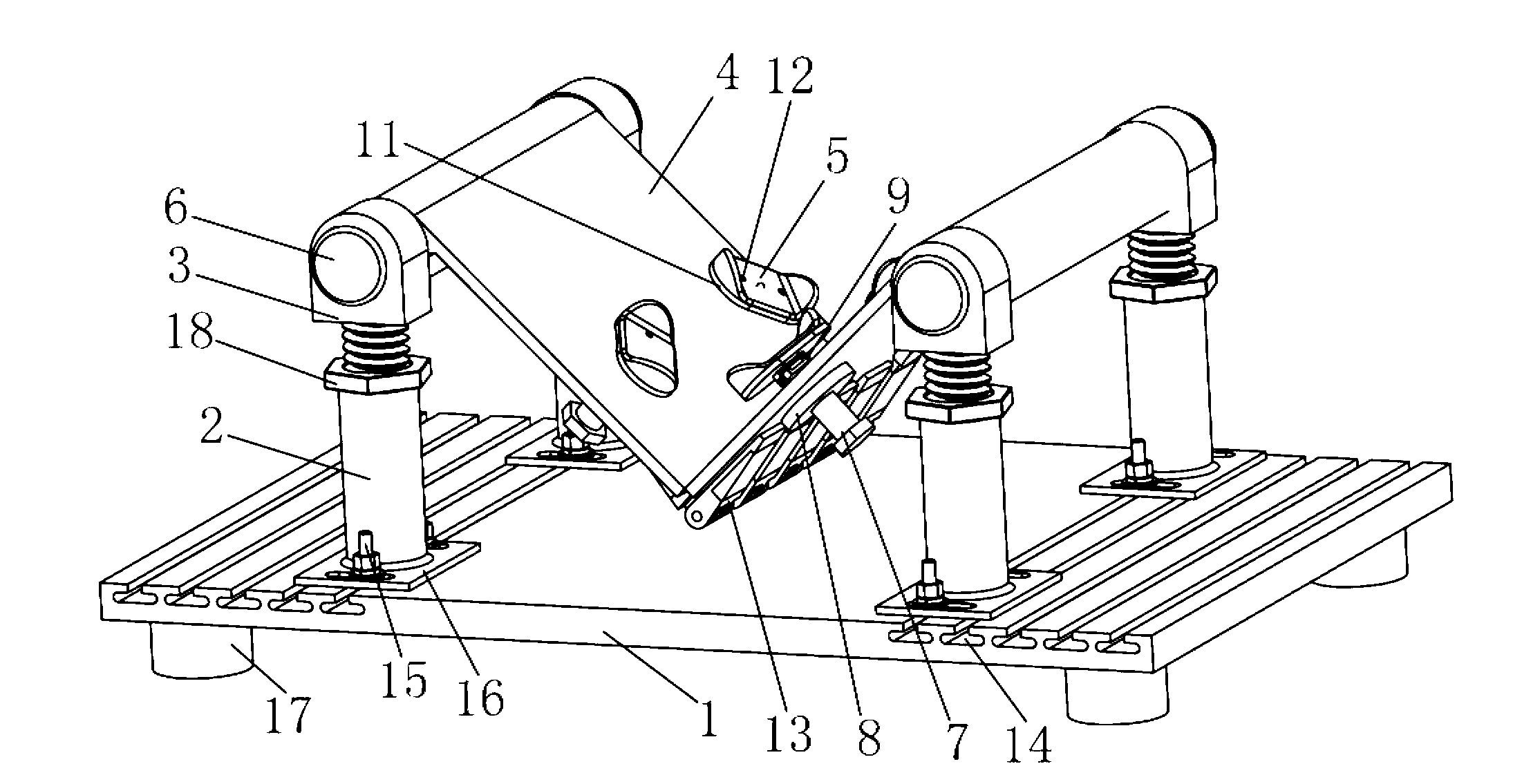

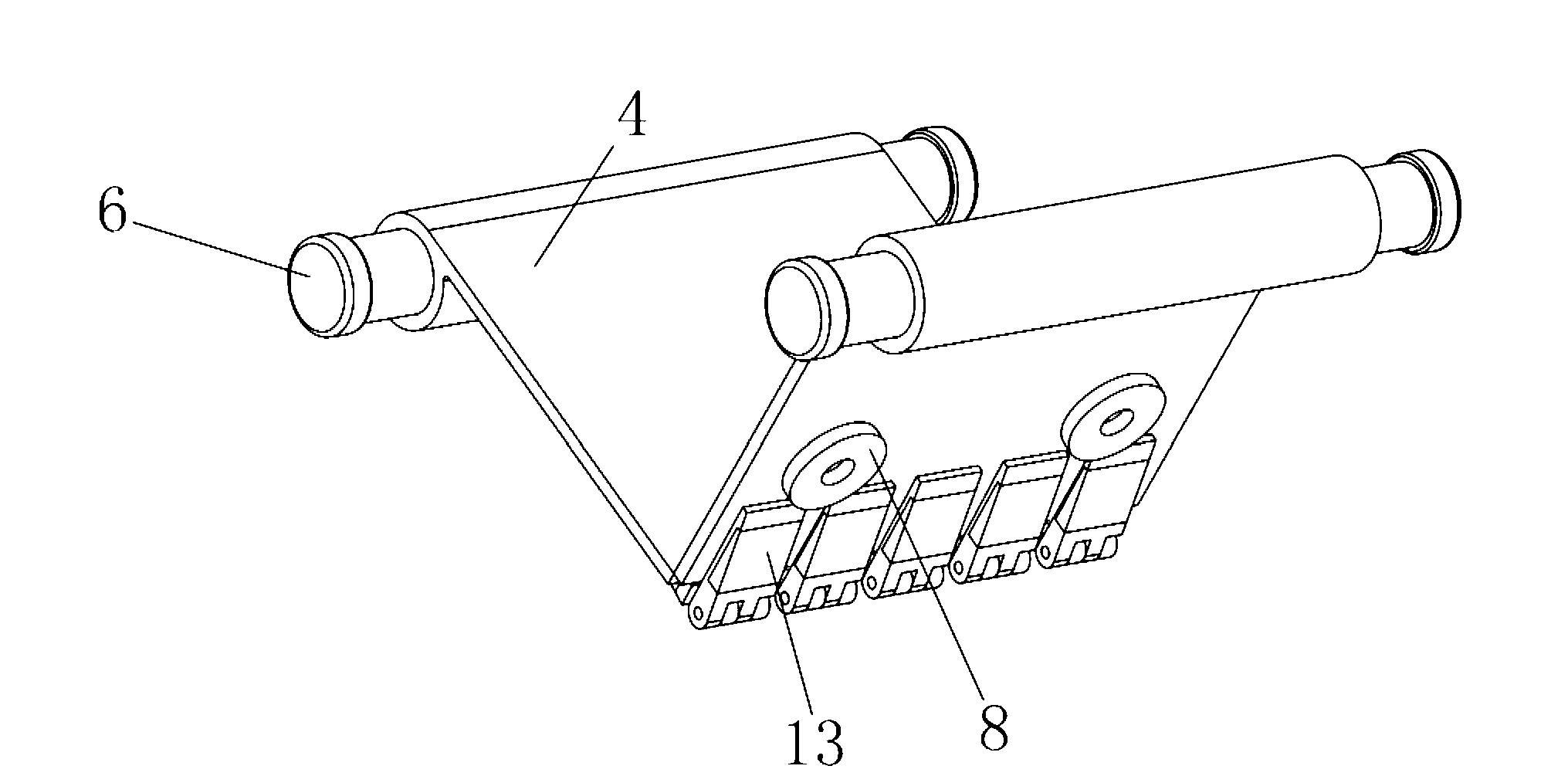

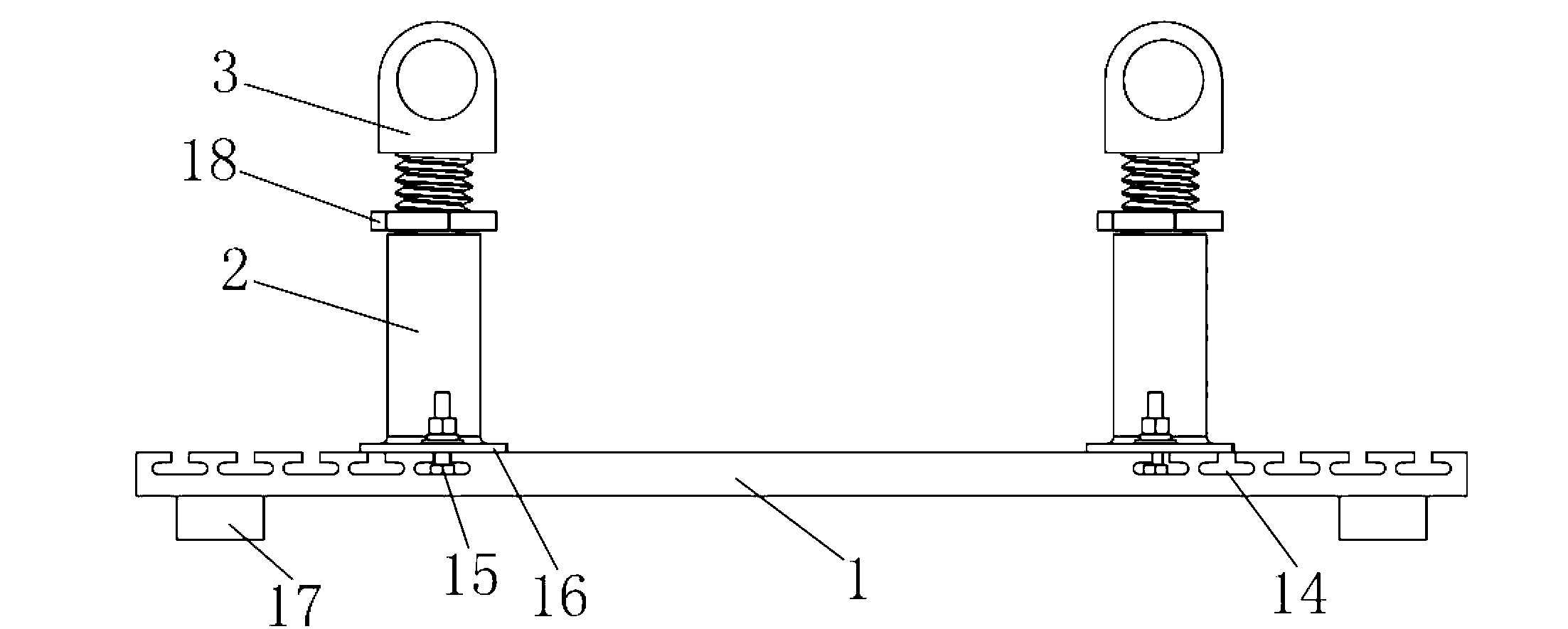

[0027] See Figure 1 to Figure 5 As shown, the new energy vehicle motor V-type installation and adjustment device of the present invention includes a base plate base 1, four screw leg bases 2, four screw legs 3, two supporting plates 4 and at least two thrust rubbers 5 , the four screw leg bases 2 are symmetrically installed on the base plate base 1 in twos, and the four screw legs 3 are threadedly engaged in the four screw leg bases 2 respectively. One end of the supporting plate 4 is hinged to each other and the other end is rotatably arranged between the two screw legs 3 to form a V-shaped bracket, and at least two of the thrust rubbers 5 are respectively arranged on two on the pallet 4.

[0028] Specifically, the supporting plate 4 can adopt No. 45 steel p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com