A method for manufacturing a sealing material for gas drainage holes

A technology of sealing material and gas drainage, applied in the field of mining material utilization, can solve the problems of high cost, failure of sealing operation, failure of sealing material, etc., and achieve good sealing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the technical solutions in the embodiments of the present invention will be clearly and completely described below.

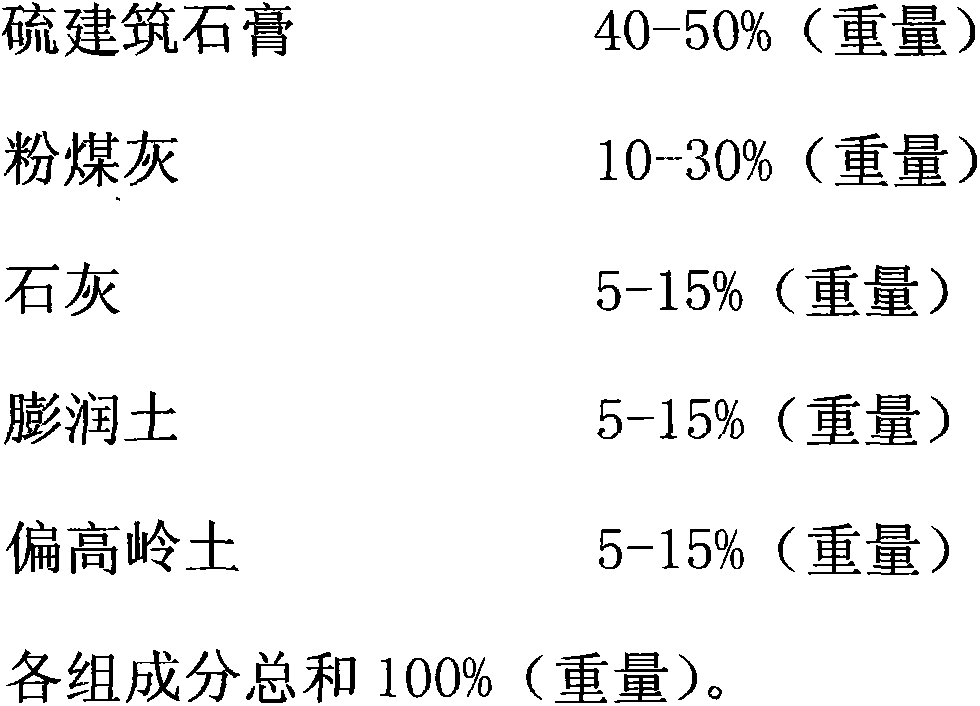

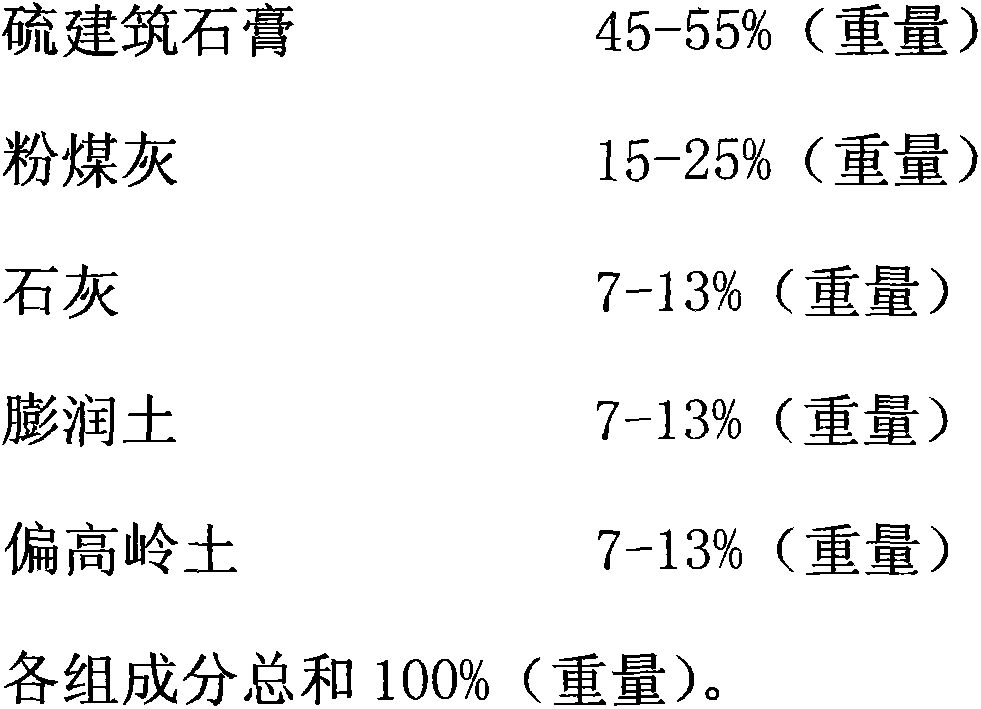

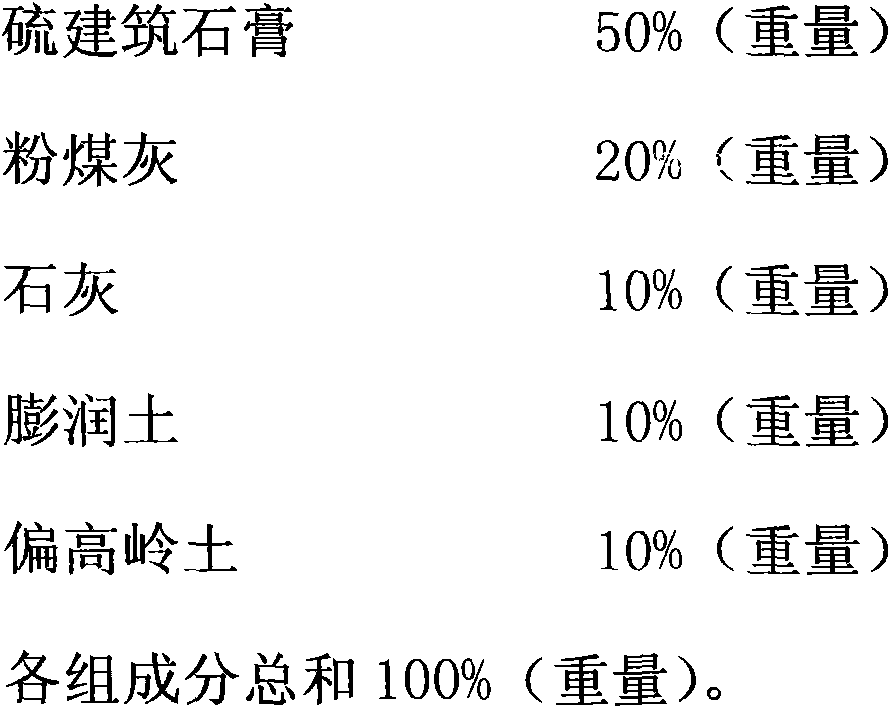

[0016] This specific embodiment adopts following technical scheme to realize, and it is made up of sulfur construction gypsum, fly ash, lime, bentonite and metakaolin, and its composition scope is:

[0017]

[0018] The manufacturing method of the sealing material is:

[0019] 1. Process sulfur building gypsum, fly ash, lime, bentonite and metakaolin into powders with a fineness of not less than 200 mesh;

[0020] 2. Mix the processed sulfur building gypsum, fly ash, lime, bentonite and metakaolin according to the proportion to get the product.

[0021] When in use, just mix water and the sealing material at a ratio of 0.5:1 and then use it.

[0022] Due to the adoption of the above technical scheme, the present invention ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com