Drying room with good drying effect

A drying room and drying technology, which is applied in the direction of preliminary treatment, drying, and drying machine to promote the drying of solid materials, can solve the problems of reduced evaporation effect, labor cost, and increased energy consumption, and achieve the improvement of automatic operation level , improve stability and continuity, and reduce energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

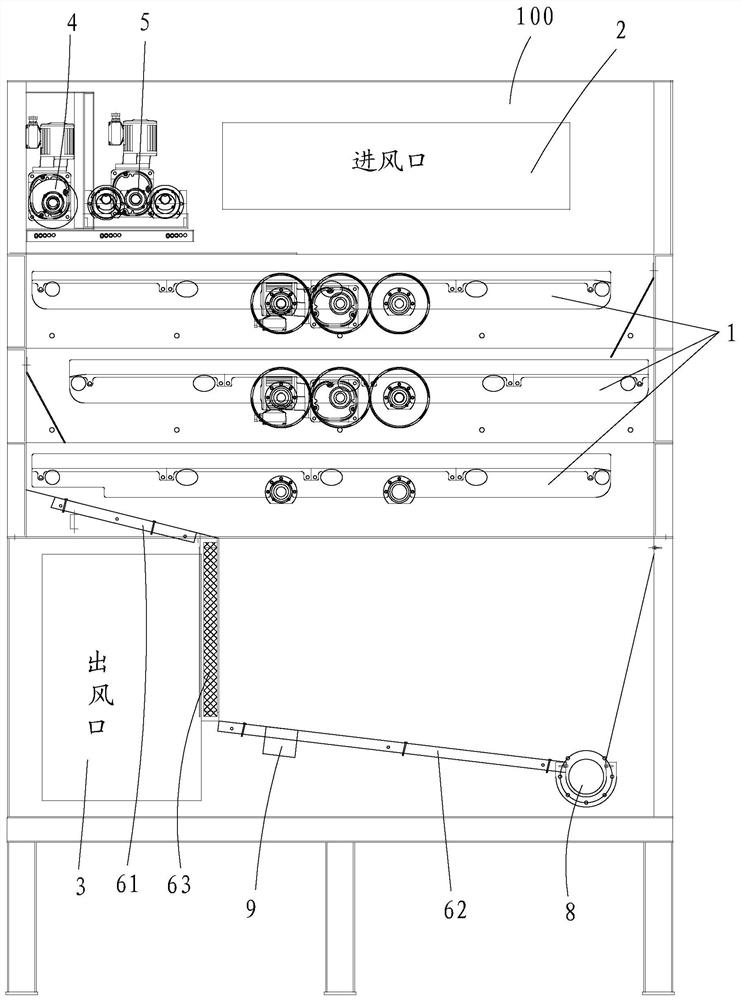

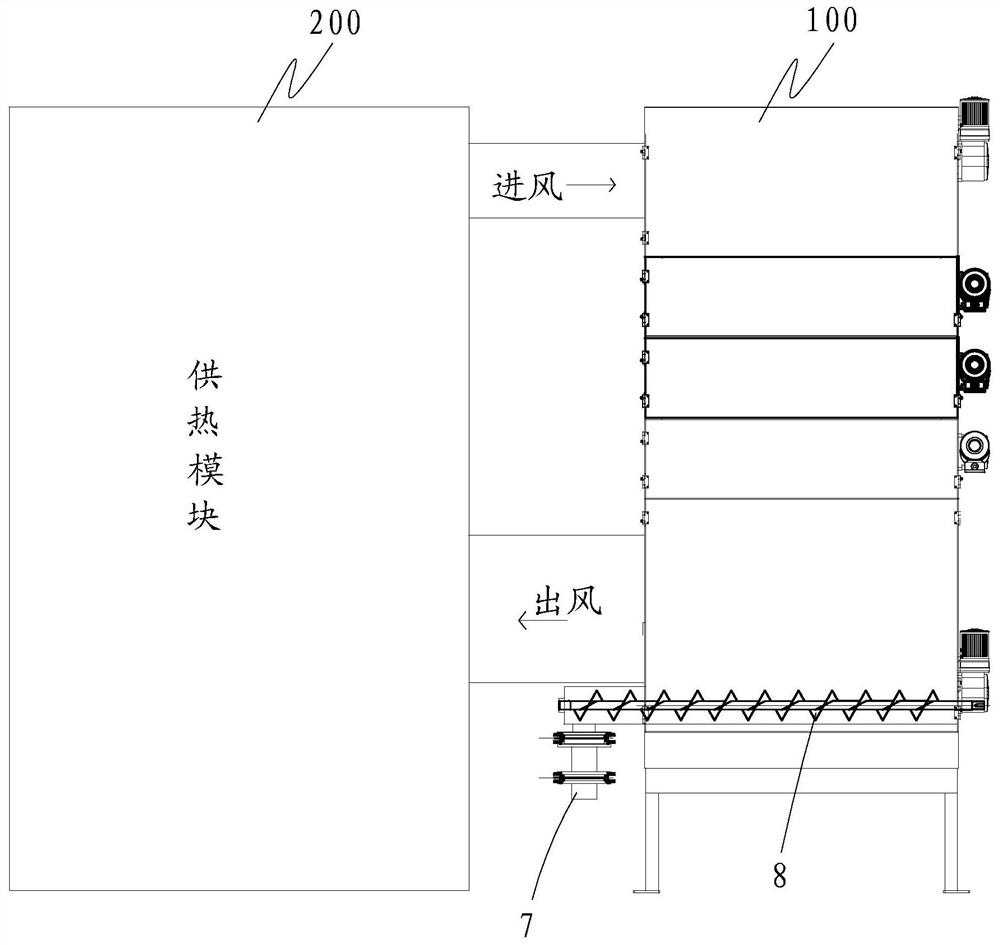

[0025] Such as figure 1 and figure 2 As shown, a drying room 100 with good drying effect is provided with a plurality of material delivery platforms 1 from top to bottom. Air outlet 3 is set below. Both the air inlet 2 and the air outlet 3 are connected to the heating module 200 , and the heating module 200 supplies hot air to the drying room 100 through the air inlet 2 . A blower or an air induction device (not shown) may be provided at the air outlet 3 for guiding the flow of the air and promoting the circulation of the air in the drying room 100 .

[0026] The specific structure of the drying room 100 in this embodiment is a modular drying room. For details, please refer to a drying room disclosed in Chinese invention patent ZL202010175357.9. The difference is that the drying room disclosed in the second embodiment of the specification of this document Each layer of material rolling conveying module in the chamber includes two layers of conveying platforms (each layer o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com