Inspection well of injection molding sewage draining pipe

A technology for inspection wells and pipe fittings, applied in the field of inspection wells, can solve the problems of reduced adhesion coefficient, unmanageable, easy to pull off, etc., to improve the transmission of strength and bearing force, ensure service life, and increase the effect of adhesion coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

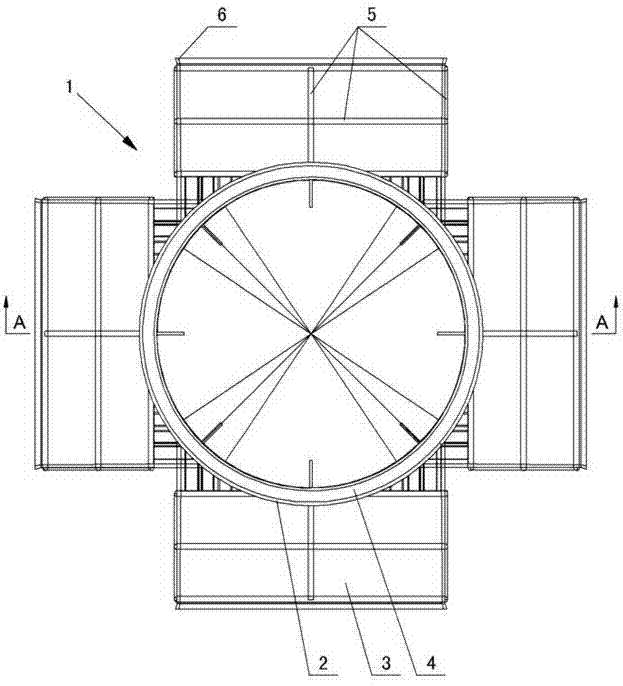

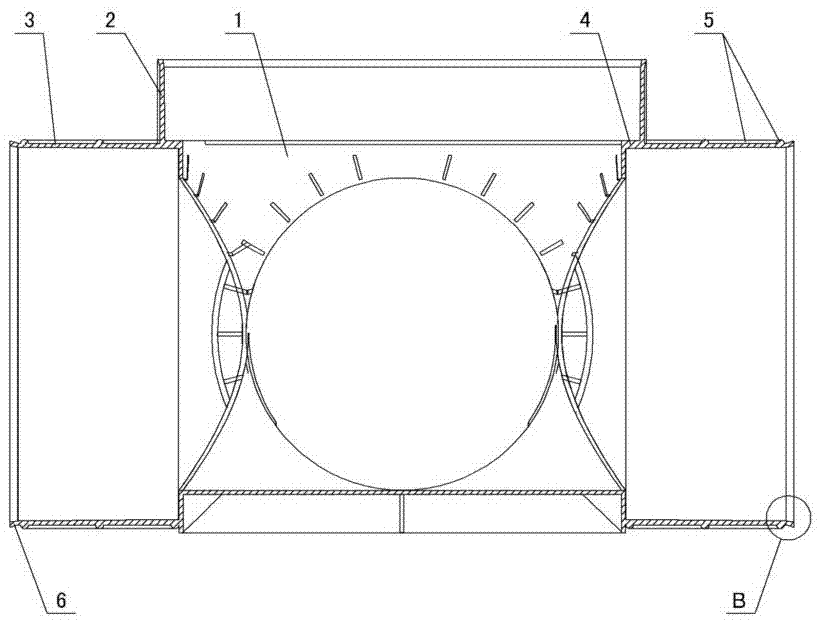

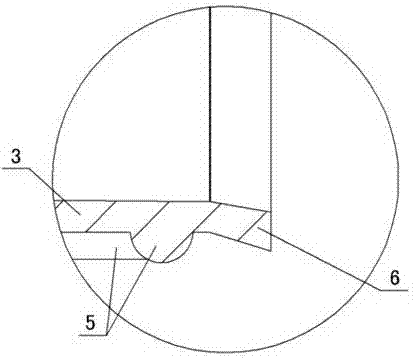

[0012] The invention relates to an inspection well for injection molded blowdown pipe fittings, such as figure 1 — Figure 5 As shown, it includes a main body 1, a vertical pipe connection port 2 and a horizontal pipe connection port 3. It is characterized in that: the vertical pipe connection port 2 is formed with a 360° force platform 4, and the vertical pipe connection port 2 is connected to the horizontal pipe. The mouth portion inner wall and the outer wall of mouth 3 are all shaped with protruding horn-shaped flared mouth 6. By forming a 360° force-bearing platform 4 on the inner wall end surface of the vertical pipe connection port 2 of the injection molding inspection well, a protruding horn-shaped flare 6 is formed on the inner wall and the outer wall of the mouth of the vertical pipe connection port and the horizontal pipe connection port 3 at the same time, The 360° force-bearing platform 4 is in contact with the lower end surface of the wellbore pipe, and the forc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com