Connecting element for plate connection

A plate connection and connector technology, applied in the direction of thin plate connection, connection components, threaded fasteners, etc., can solve the problems of failure to meet the use requirements, low efficiency, high labor intensity, etc., to increase the force area, Firm fixing and quick assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

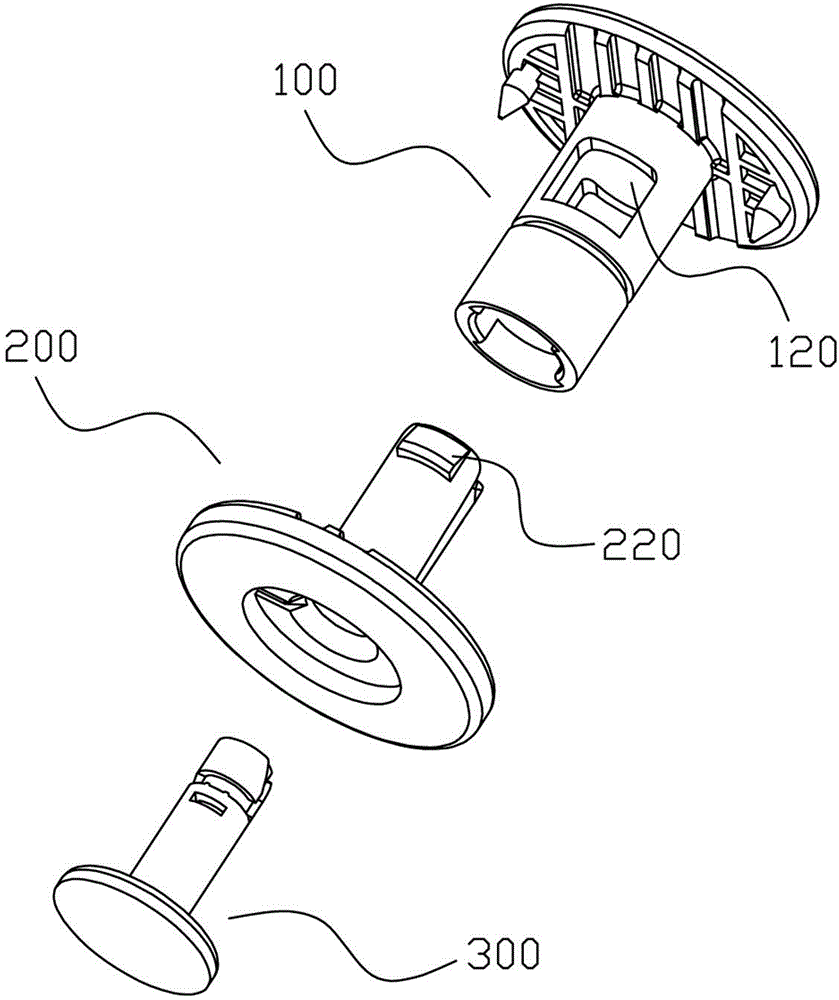

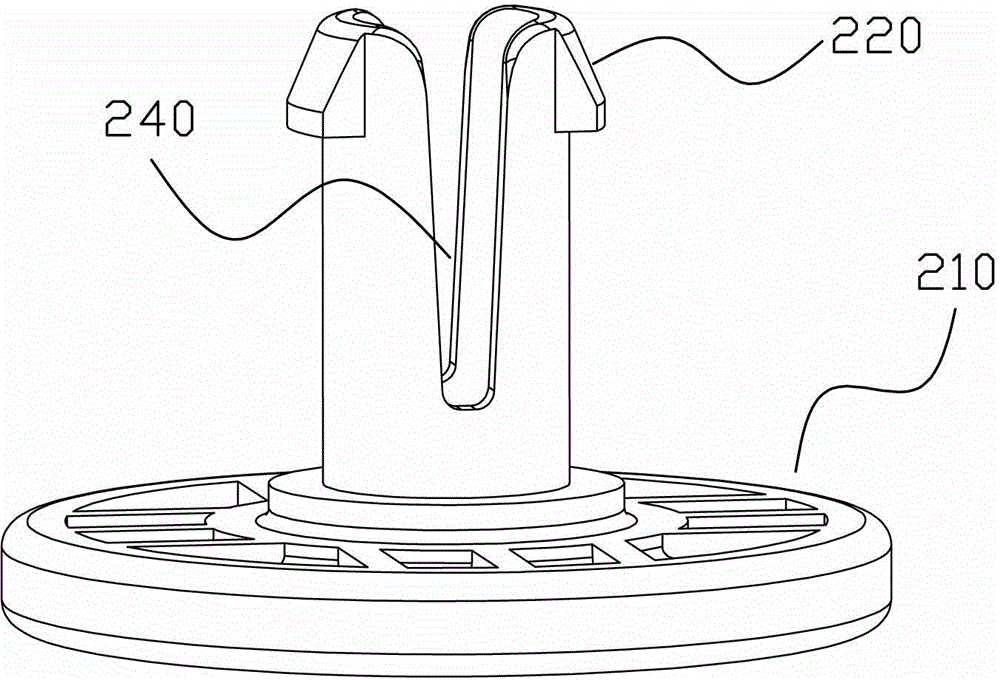

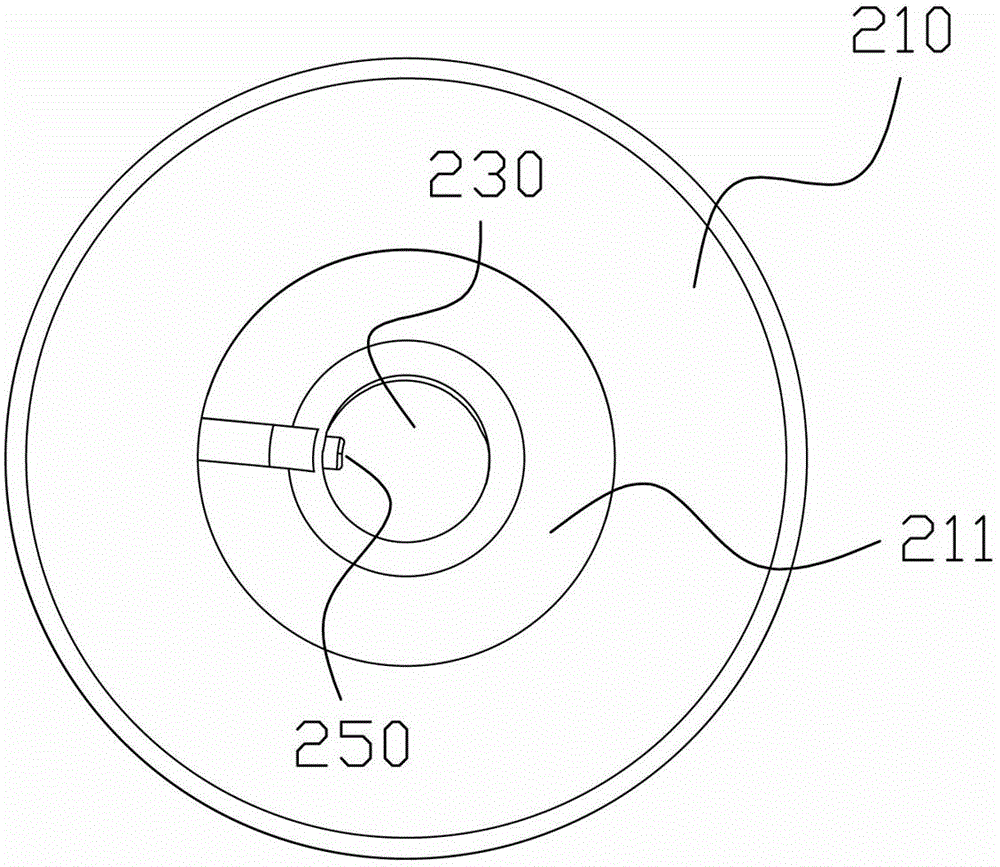

[0020] Such as figure 1 The shown connecting piece for plate connection includes a sleeve 100 with a T head and a sleeve rod 200 with a T head. The sleeve rod 200 is inserted into the sleeve 100 and engages with the sleeve 100 so that all The above-mentioned connecting piece is I-shaped. When the connecting piece is used for suturing and fixing the plates, it is necessary to open the corresponding mounting holes of the plates to be connected first, and then insert the cylindrical part of the sleeve 100 into the mounting holes of the plates to be connected, and then Insert the sleeve rod 200 into the barrel of the sleeve 100, and engage with the sleeve 100. The connected plates are clamped by the sleeve 100 and the T head (110, 210) of the sleeve rod 200, using multiple connectors According to the volume of the packing box and the size of the force, the T head (110, 210) of the sleeve 100 and the sleeve rod 200 can be designed into different sizes, and the T head of the sleeve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com