Building concealed circuit threader

A technology for wire threaders and buildings, applied to electrical components, cable laying equipment, etc., can solve the problems of high labor intensity, low work efficiency, waste of working hours, etc., and achieve the effects of low labor intensity, high work efficiency and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The general idea of the present invention is to drive the traction wire forward and backward through the remote control motor to carry out the traction and installation operation of the wire in the wall. An embodiment is described below in conjunction with the accompanying drawings:

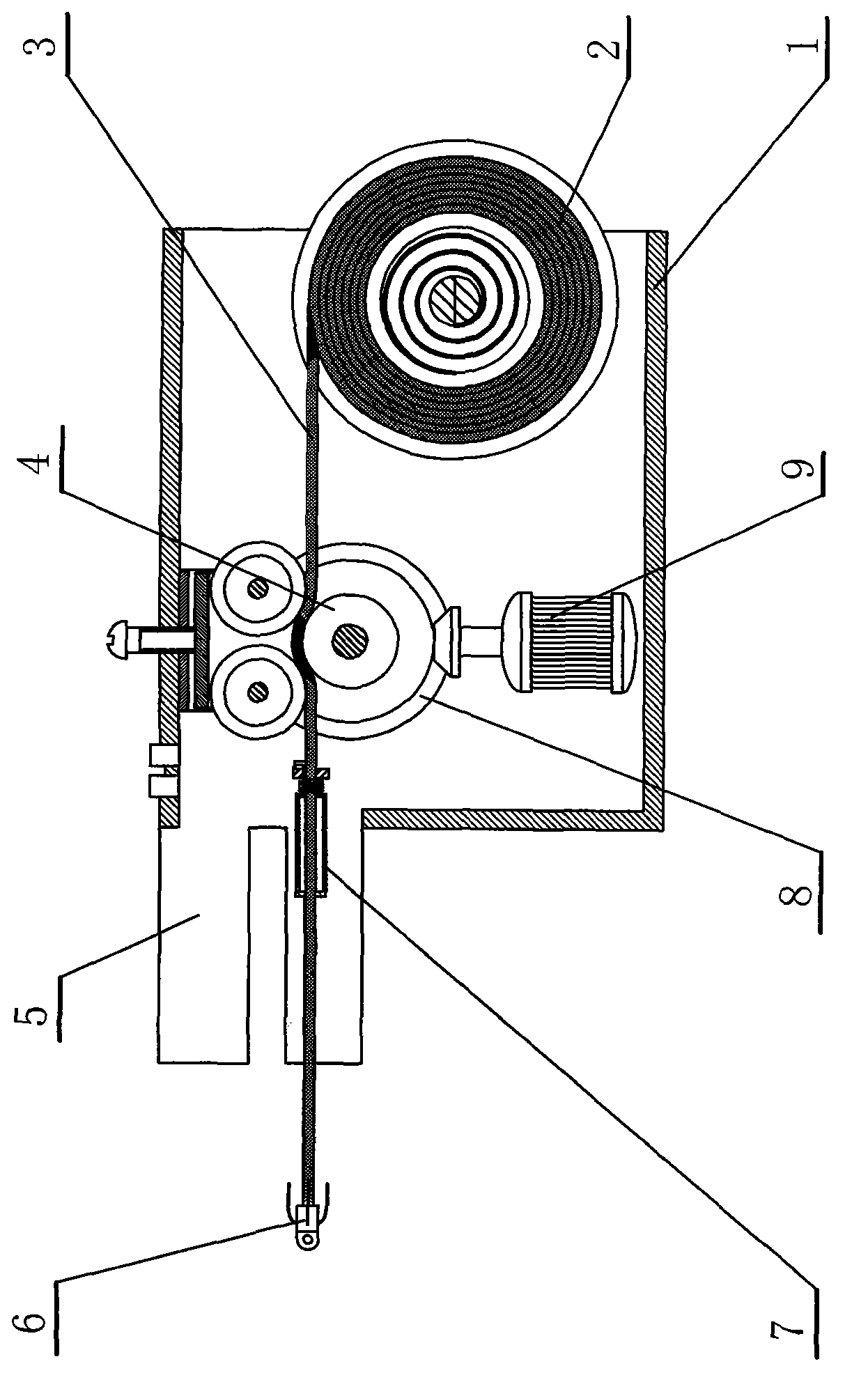

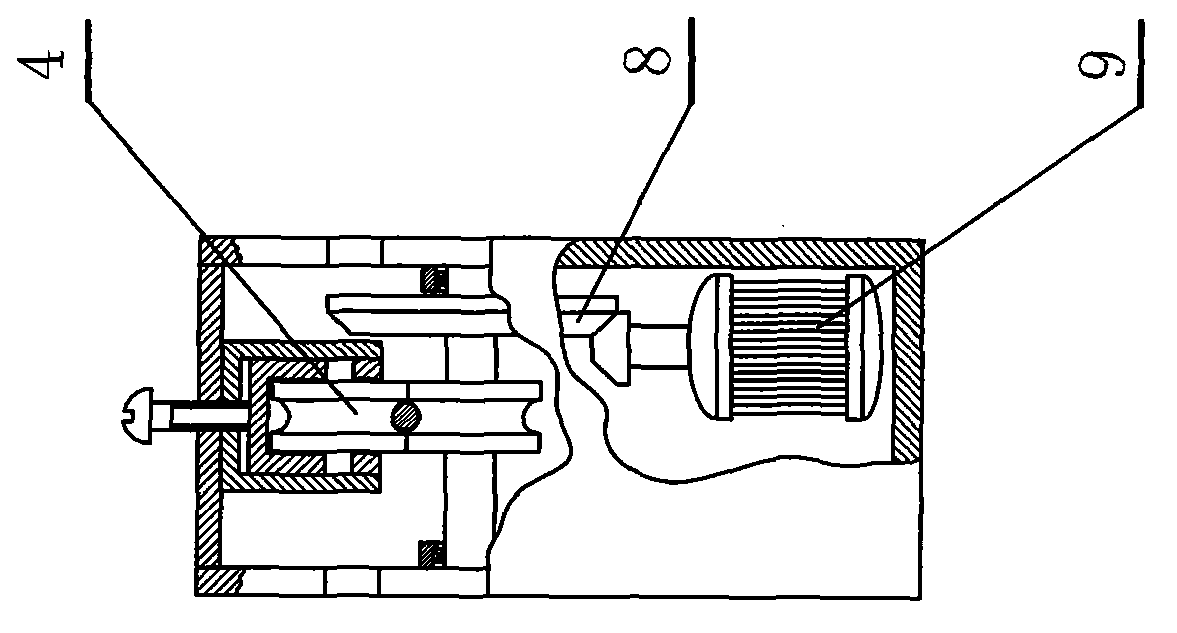

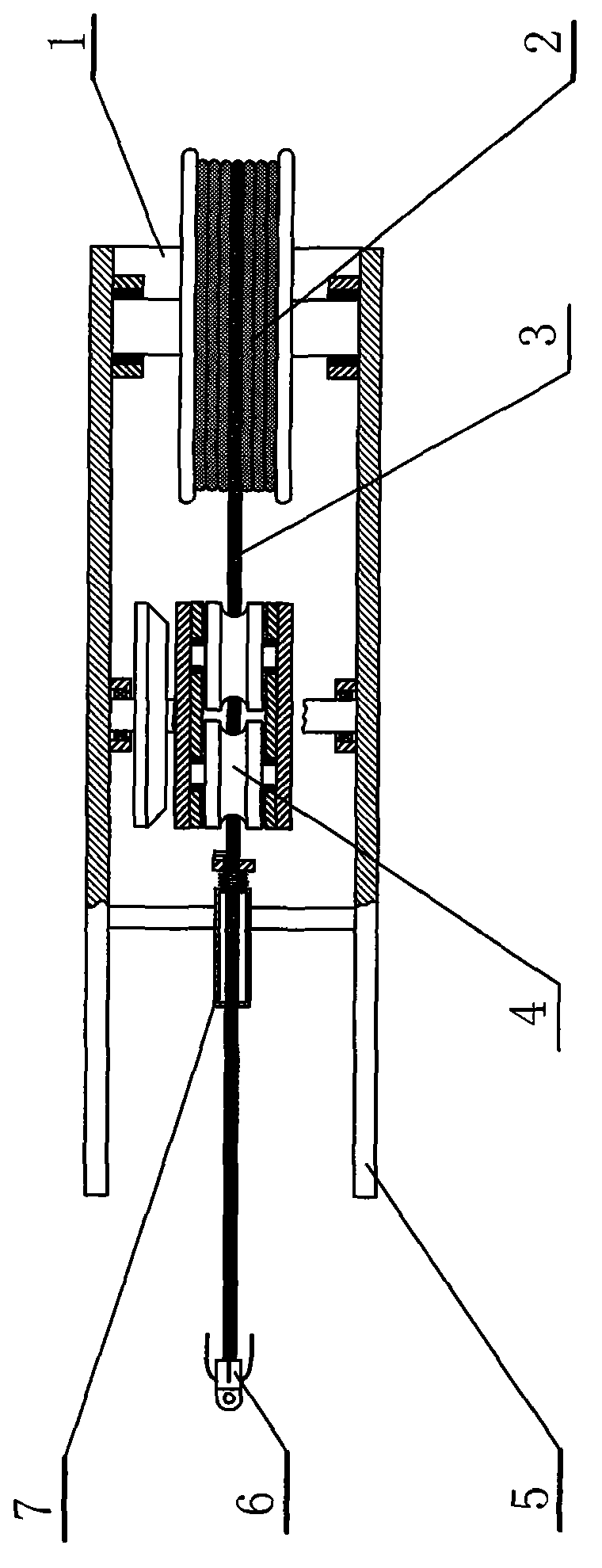

[0032] figure 1 , 2 , 3 introduce a threader, a reel 2 and a clamping mechanism 4 are arranged in a casing 1, and the clamping mechanism clamps the traction wire 3 under the drive of the motor 9 to realize the forward or reverse action.

[0033] combine Figure 4 , 5 , 6, it can be seen that the shell 1 is in the shape of a flat cube, and the front part is provided with four inserts 5, which can be inserted into the wire box on one side of the conduit. The upper surface of the housing 1 is provided with an indicator light 10, and one side is provided with a forward rotation button 11 and a reverse rotation button 12.

[0034] combine Figure 7 , 8 It can be seen that the reel 2 ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com